A kind of high-voltage solid-state battery composite positive electrode and preparation method thereof

A composite cathode, solid-state battery technology, used in battery electrodes, positive electrodes, lithium batteries, etc., can solve the problems of low battery cut-off voltage, difficult to match high-voltage positive stage, etc., to achieve increased volume energy density, low impedance, and enhanced lithium ion The effect of diffusivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

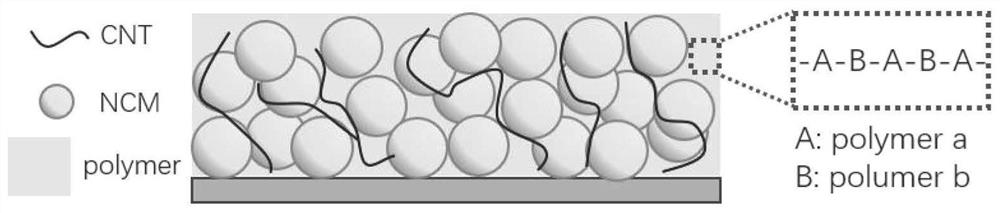

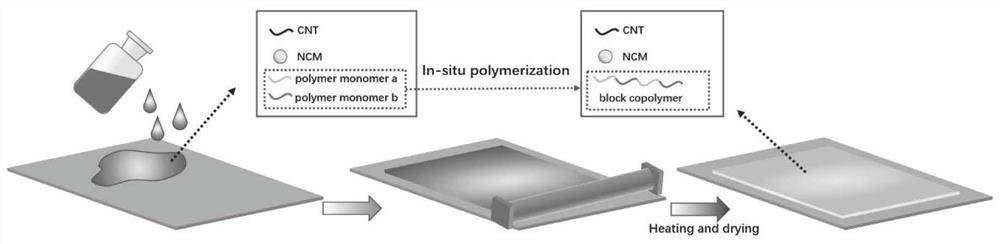

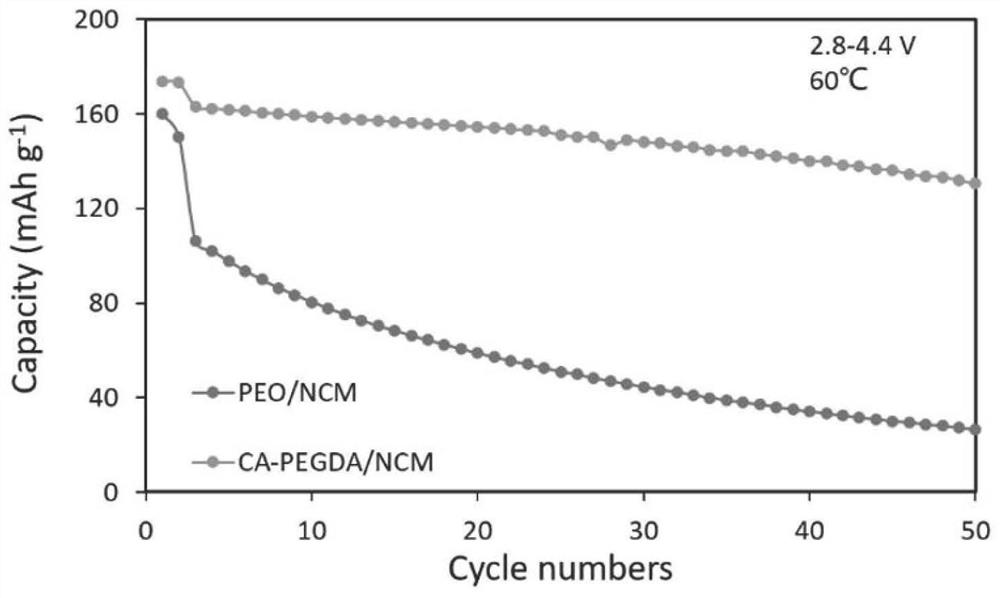

[0026] Embodiment 1: This embodiment describes a composite positive electrode for a high-voltage solid-state battery, and the composite positive electrode includes lithium salt, LiNi 0.8 Co 0.1 Mn 0.1 O 2 , block copolymers and carbon nanotubes. Among them, LiNi 0.8 Co 0.1 Mn 0.1 O 2 As cathode active materials, block copolymers act as binders, and carbon nanotubes (CNTs) have high electrical conductivity. like figure 1 shown, which is a schematic diagram of the structure of the composite cathode, the block copolymer electrolyte replaces the traditional binder with conductive Li + The block monomer used contains -CN functional group, which can reduce the catalytic activity of the transition metal on the ternary surface, so the prepared positive stage has good high-pressure performance. Moreover, the method of in-situ polymerization is adopted, and the prepared composite positive grade has high density, and the assembled all-solid-state lithium battery has high volume...

specific Embodiment approach 2

[0027] Embodiment 2: According to Embodiment 1, a high-voltage-resistant solid-state battery composite positive electrode, the monomers of the block copolymer are ethyl cyanoacrylate (ECA), polyethylene oxide (PEO), polyethylene Alcohol (PVA), Polyvinylidene Fluoride (PVDF), Polyethylene Glycol, Polymethyl Methacrylate (PMMA), Polyethylene Glycol (Diol) Diacrylate (PEGDA), Polyvinyl Carbonate (PPC) any two of them.

specific Embodiment approach 3

[0028] Embodiment 3: According to Embodiment 1, a high-voltage-resistant solid-state battery composite positive electrode, the lithium salt is lithium perchlorate (LiClO 4 ), lithium hexafluorophosphate (LiPF 6 ), lithium bistrifluoromethanesulfonimide (LiTFSI), lithium hexafluoroarsenate (LiAsF 6 ), lithium tetrafluoroborate (LiBF 4 )one of a kind.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com