Aluminum-magnesium-yttrium intermediate alloy prepared by magnesiothermic reduction method and preparation method of aluminum-magnesium-yttrium intermediate alloy

A technology of master alloy and reduction method, applied in the field of rare earth aluminum master alloy, can solve the problems of inability to show alloying effect, many impurities and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

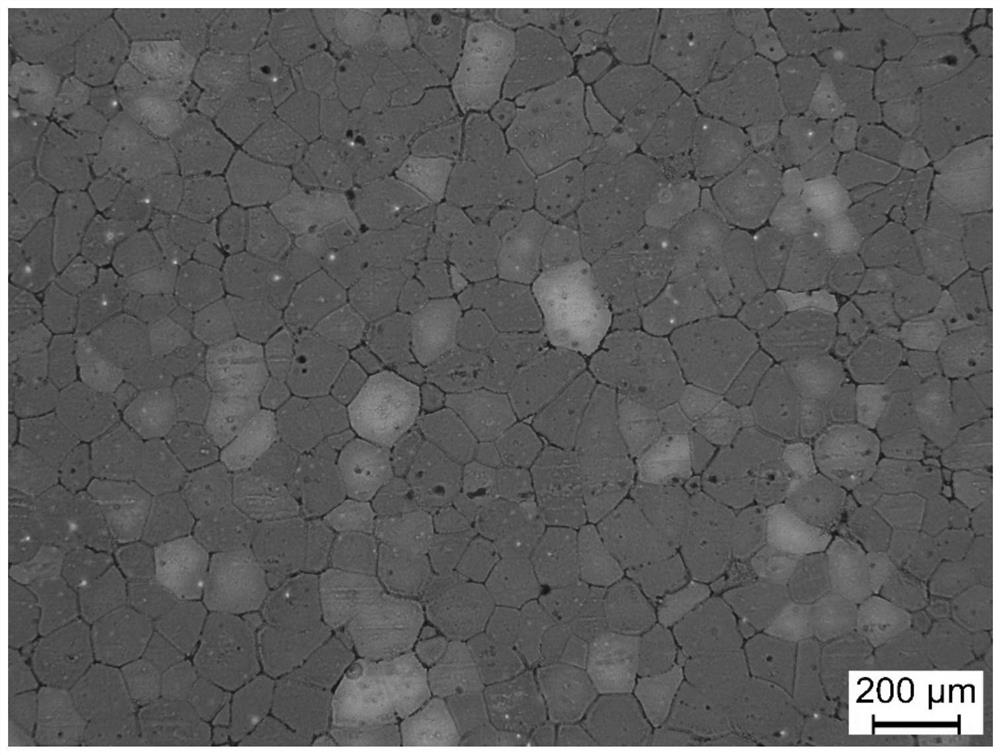

Image

Examples

Embodiment 1

[0038] A method for preparing aluminum-magnesium-yttrium master alloy by magnestic reduction method comprises the following steps:

[0039] (1) Calculate and weigh metal aluminum, metal magnesium, yttrium fluoride, lithium fluoride, sodium fluoride, sodium chloride, Potassium chloride, calcium fluoride, magnesium fluoride, aluminum fluoride, spare;

[0040] (2) The mass percent of each component in the mixed salt is: lithium fluoride 10%, sodium fluoride 15%, sodium chloride 20%, potassium chloride 30%, calcium fluoride 5%, magnesium fluoride 8%, Aluminum fluoride 12%, use mixing equipment to mix it evenly; the consumption of described mixed salt is 4 times of yttrium fluoride weight;

[0041] (3) Put metal aluminum in an aluminum alloy melting furnace and heat up to 740°C to melt, add metal magnesium in proportion and keep it warm to make it melt completely, add the prepared mixed salt in proportion and heat up to 850°C, and the mixed salt is completely melted, get melt 1; ...

Embodiment 2

[0047] A method for preparing aluminum-magnesium-yttrium master alloy by magnestic reduction method comprises the following steps:

[0048] (1) Calculate and weigh metal aluminum, metal magnesium, and yttrium compounds (yttrium fluoride, yttrium chloride), sodium fluoride, and , potassium fluoride, sodium chloride, potassium chloride, magnesium fluoride, aluminum fluoride, spare;

[0049] (2) The mass percentages of each component in the compound of yttrium are: 40% of yttrium fluoride, 60% of yttrium chloride, which are mixed uniformly and set aside;

[0050] (3) The mass percent of each component in the mixed salt is: sodium fluoride 15%, potassium fluoride 10%, sodium chloride 30%, potassium chloride 30%, magnesium fluoride 10%, aluminum fluoride 5%, Use mixing equipment to mix it evenly; the amount of mixed salt is 5 times that of the compound of yttrium;

[0051] (4) Put metal aluminum in an aluminum alloy melting furnace and heat up to 740°C to melt, add metal magnesiu...

Embodiment 3

[0056] A method for preparing aluminum-magnesium-yttrium master alloy by magnestic reduction method comprises the following steps:

[0057] (1) Calculate and weigh metal aluminum, metal magnesium, yttrium compounds (yttrium chloride, yttrium bromide), lithium fluoride, and , sodium fluoride, sodium chloride, potassium chloride, sodium bromide, potassium iodide, magnesium fluoride, aluminum fluoride;

[0058] (2) The mass percentages of each component in the compound of yttrium are: 70% of yttrium chloride, 30% of yttrium bromide, which are mixed uniformly and set aside;

[0059] (3) The mass percentage of each component in the mixed salt is: lithium fluoride 10%, sodium fluoride 15%, sodium chloride 20%, potassium chloride 25%, sodium bromide 8%, potassium iodide 8%, fluoride Magnesium 5%, aluminum fluoride 9%, use mixing equipment to mix them evenly; the amount of mixed salt is 3 times that of yttrium compound;

[0060] (4) Put the metal aluminum into an aluminum alloy melt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com