Thermal treatment method for Al-Zn-Mg-Sc-Zr alloy

A heat treatment method and alloy technology, which are applied in the field of cold rolling treatment of Al-Zn-Mg-Sc-Zr alloy after hot rolling and before solid solution, can solve the problem that the overall performance of the alloy is reduced, the alloy cannot be completely dissolved into the matrix, and the alloying is reduced. The effect of improving mechanical properties, convenient operation, and increasing the degree of supersaturation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

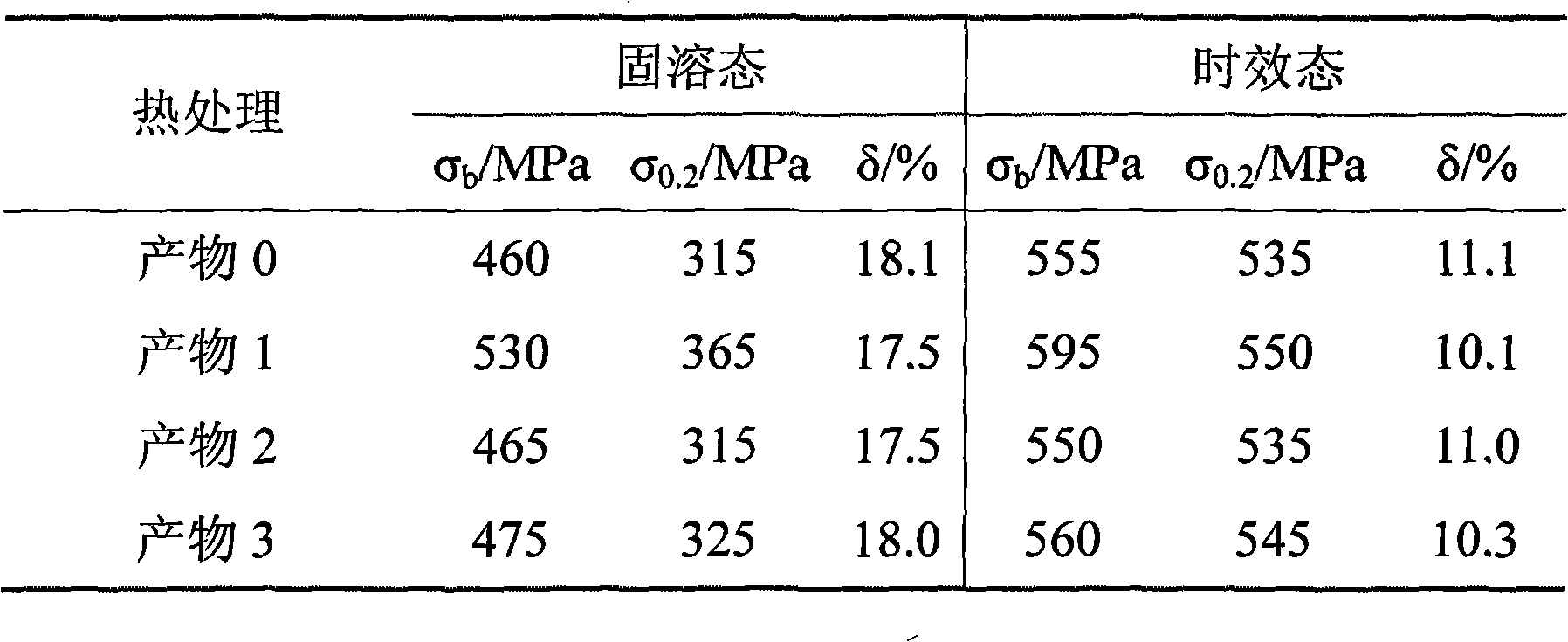

example 1

[0015] The aluminum-zinc-magnesium-scandium-zirconium alloy ingot test piece 1 is carried out:

[0016] 1. Hot rolling: 430°C, after 8 passes of hot rolling to 5mm, the deformation is 83.3%;

[0017] 2. Solid solution: heat preservation at 500°C for 1.5h, water quenching;

[0018] 3. Cold rolling: After 3 passes of cold rolling to 2.5mm, the deformation is 50.0%;

[0019] 4. Solid solution: heat preservation at 505°C for 2 hours, water quenching;

[0020] 5. Aging: Aging at 120-130°C for 20-26 hours, and air cooling after being out of the oven. The final product 1 was obtained.

example 2

[0022] The aluminum-zinc-magnesium-scandium-zirconium alloy ingot test piece 2 is carried out:

[0023] 1. Hot rolling: 400℃, after 8 passes of hot rolling to 5mm, the deformation is 83.3%;

[0024] 2. Solid solution: heat preservation at 450°C for 1 hour, water quenching;

[0025] 3. Cold rolling: After 2 passes of cold rolling to 3mm, the deformation is 40.0%;

[0026] 4. Solid solution: heat preservation at 505°C for 1 hour, water quenching;

[0027] 5. Aging: aging at 120-130℃ for 20-26h. Remove from the oven and air cool. The final product 2 was obtained.

example 3

[0029] The aluminum zinc magnesium scandium zirconium alloy ingot test piece 3 is carried out:

[0030] 1. Hot rolling: 400-450°C, after 8 passes of hot rolling to 5mm, the deformation is 83.3%;

[0031] 2. Solid solution: heat preservation at 500°C for 3 hours, water quenching;

[0032] 3. Cold rolling: After 3 passes of cold rolling to 2mm, the deformation is 60%;

[0033] 4. Solid solution: heat preservation at 505°C for 1 hour, water quenching;

[0034] 5. Aging: aging at 120-130℃ for 20-26h. Remove from the oven and air cool. The final product 3 was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com