Metal surface mechanically-assisted electric heat alloying preparation method

An electrothermal alloy and mechanically assisted technology, applied in the coating process and coating of metal materials, can solve the problems of difficult control of surface roughness, complex process, large coating thickness, etc., and achieve low processing cost and high quality reinforcement layer , the effect of dense alloying layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] see figure 1 Shown, a kind of preparation method of metal surface mechanically assisted electrothermal alloying, its operation steps are as follows:

[0040] Step 1. Pretreatment of metal workpiece substrate to be alloyed:

[0041] The industrial pure titanium (TA2) plate of 20mm×20mm×2mm is used as the substrate of the metal workpiece to be alloyed, and the oil, scale and work hardening layer on the surface of the industrial pure titanium plate are removed by sandblasting and grinding, and fixed on the working platform for use;

[0042] Step 2. Electrothermal alloying electrode preparation: Fasten the surface of the metal brush body with a stainless steel wire with a diameter of 0.05 mm, and make a density of 3000 wires / cm 2 , the brush of 40 * 40mm, as the electrode material that carries out Cr, Fe (the main component in the stainless steel) co-infiltration in the air, stand-by;

[0043] Step 3. Assembly of electrothermal alloying equipment: fix the brush prepared i...

Embodiment 2

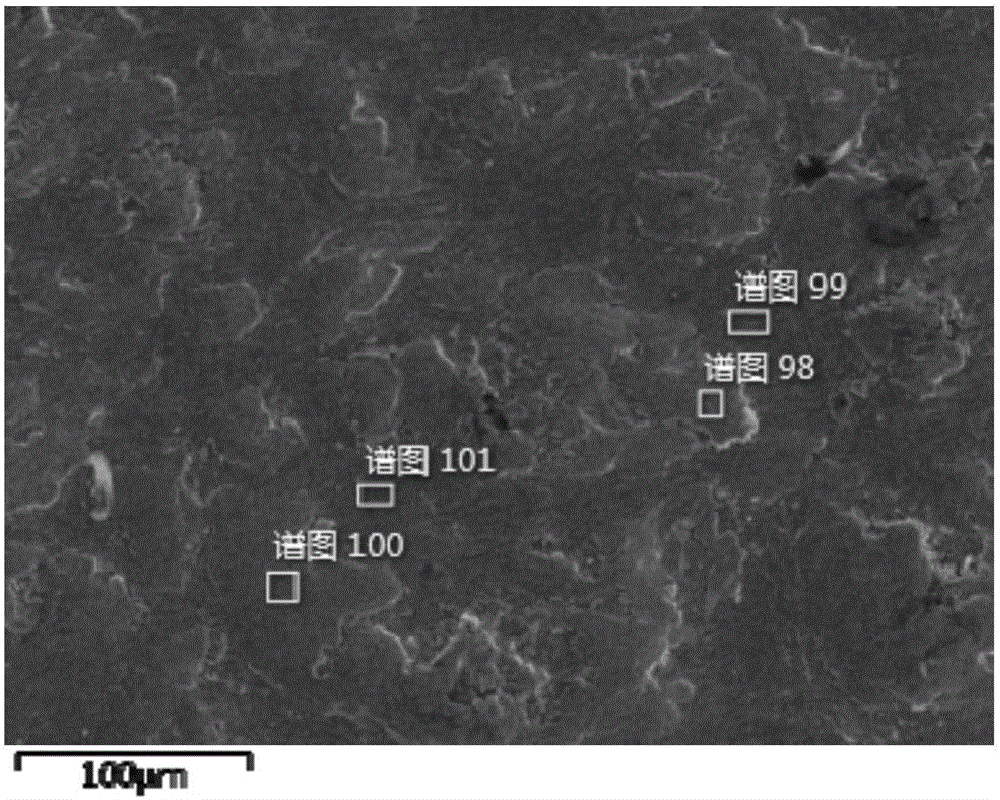

[0049] see figure 2 Shown, a kind of preparation method of metal surface mechanically assisted electrothermal alloying, its operation steps are as follows:

[0050] Step 1. Pretreatment of metal workpiece substrate to be alloyed:

[0051] The industrial pure titanium (TA1) plate of Φ90×2mm is used as the substrate of the metal workpiece to be alloyed, and the oil, scale and work hardening layer on the surface of the industrial pure titanium plate are removed by sandblasting and grinding, and fixed on the working platform for use;

[0052] Step 2. Preparation of electrothermal alloying electrodes: fasten copper wires with a diameter of 0.2mm on the surface of the metal brush body to make a density of 500 wires / cm 2 , Φ30mm solid core brush, as the electrode material for copper infiltration (or titanium, copper alloying) treatment in the air, to be used;

[0053] Step 3. Assembly of electrothermal alloying equipment: fix the brush prepared in step 2 on the high-speed rotating...

Embodiment 3

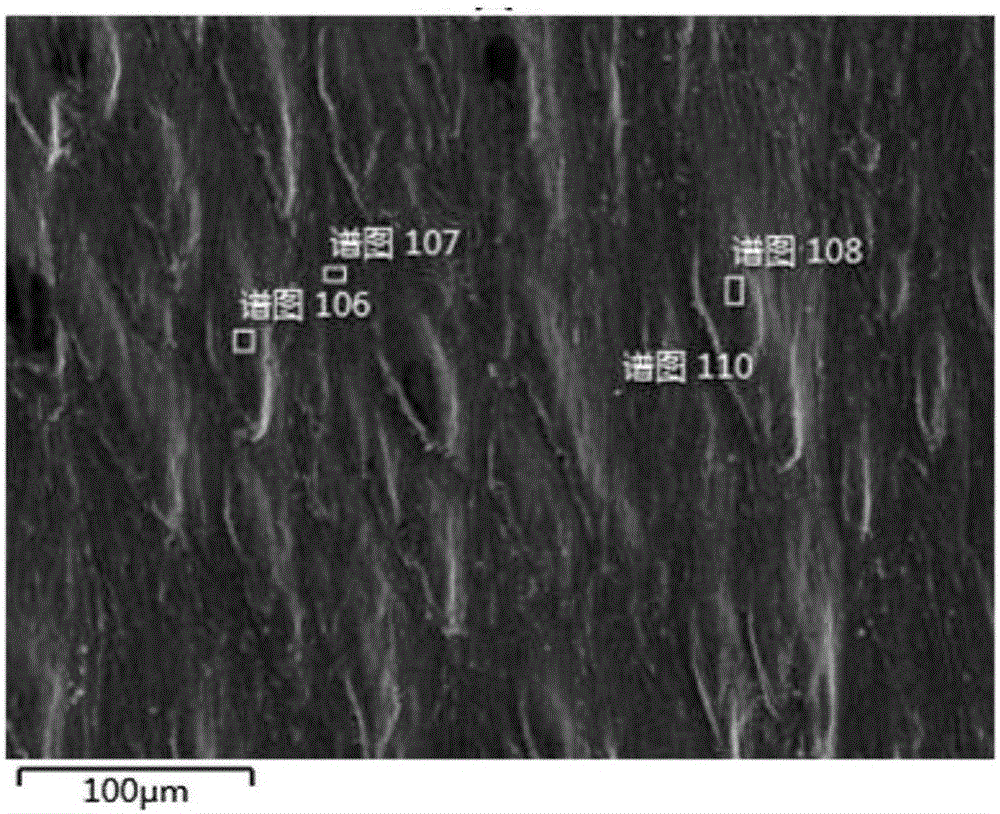

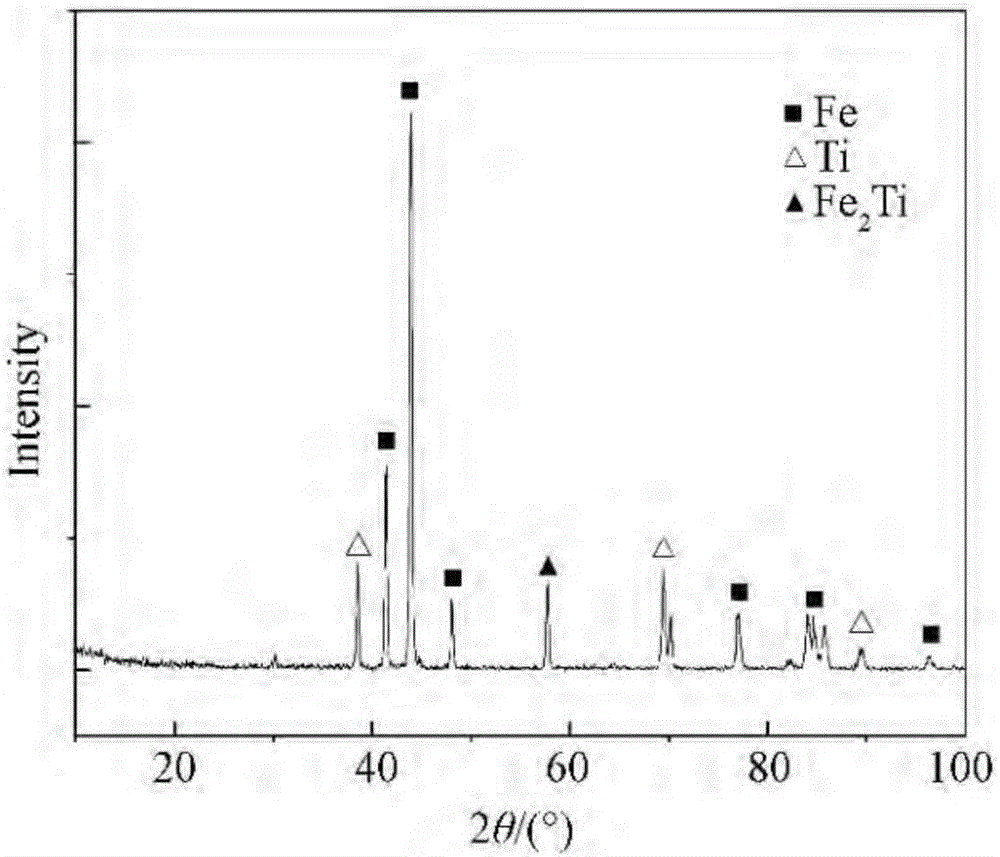

[0060] see image 3 Shown, a kind of preparation method of metal surface mechanically assisted electrothermal alloying, its operation steps are as follows:

[0061] Step 1. Pretreatment of metal workpiece substrate to be alloyed:

[0062] Use No. 45 steel plate of Φ60×2mm as the substrate of the metal workpiece to be alloyed. After sandblasting and grinding, remove the oil, scale and work hardening layer on the surface of the No. 45 steel plate, and fix it on the working platform for use;

[0063] Step 2. Electrothermal alloying electrode preparation: 0.1mm diameter TA2 titanium wire (with low thermal conductivity) is fastened on the surface of the metal brush body, and the density is 1200 pieces / cm 2 , Φ30mm brush, as the electrode material for titanium infiltration (or titanium, steel alloying) treatment in the air, to be used;

[0064] Step 3. Assembly of electrothermal alloying equipment: fix the brush prepared in step 2 on the high-speed rotating motor, and continuously...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com