Thin-coating high-viscosity water-based polyacrylate pressure-sensitive adhesive as well as preparation method and application thereof

A technology of polyacrylate and pressure-sensitive adhesives, which is applied in the direction of adhesives, polymer adhesive additives, film/sheet adhesives, etc., and can solve the problems that cannot meet the requirements of the development of light and thin electronic devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

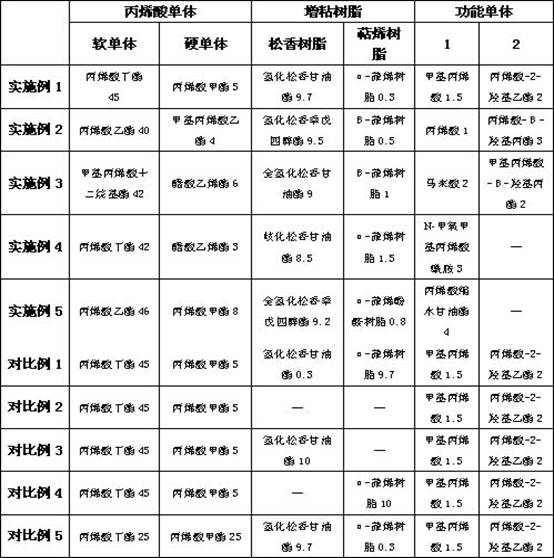

Examples

Embodiment 1

[0036] First weigh 45 parts of butyl acrylate and 5 parts of methyl acrylate in a container, heat at 60°C and slowly add 9.7 parts of hydrogenated rosin glyceride and 0.3 parts of α-pinene resin, and stir for 1 hour while adding, until completely dissolved; Add 0.5 parts of sodium lauryl sulfate, 1 part of propylene alcohol polyoxyethylene ether, 0.5 parts of potassium persulfate, 1.5 parts of methacrylic acid, and 2 parts of 2-hydroxyethyl acrylate to 20 parts in the reactor. Pre-emulsion A was obtained in deionized water; then 0.4 parts of potassium persulfate, 1 part of propylene alcohol polyoxyethylene ether, and 0.1 part of sodium bicarbonate were sequentially weighed and added to 15 parts of deionized water to obtain solution B; then the mass of pre-emulsion A was added Put 20% of the fraction in solution B, heat up to 70°C, and stir until the solution appears blue light, heat up to 84°C, then slowly add the remaining emulsion A dropwise within 2 hours, keep it warm for 2...

Embodiment 2

[0038]First weigh 40 parts of ethyl acrylate and 4 parts of ethyl methacrylate in a container, heat at 50°C and slowly add 9.5 parts of hydrogenated rosin pentaerythritol ester and 0.5 part of β-pinene resin, stir for 1 hour while adding, until completely Dissolve; Add 0.4 parts of sodium methacrylsulfonate, 0.8 parts of sodium propyl alkyl ether sulfonate, 0.5 parts of sodium persulfate, 1 part of acrylic acid, and 3 parts of β-hydroxypropyl acrylate into the reactor 20 parts of deionized water to obtain pre-emulsion A; then weigh 0.4 parts of sodium persulfate, 0.8 parts of sodium propyl alkyl ether sulfonate, and 0.1 parts of sodium bicarbonate and add them to 15 parts of deionized water to obtain solution B; then add Put 20% of the mass fraction of pre-emulsion A in solution B, heat up to 70°C, and stir until the solution appears blue light, heat up to 83°C, then slowly add the remaining emulsion A dropwise within 2 hours, keep it warm for 2 hours, and wait until the reacti...

Embodiment 3

[0040] First weigh 42 parts of lauryl methacrylate and 6 parts of vinyl acetate in a container, heat at 55°C and slowly add 9 parts of perhydrogenated rosin glyceride and 1 part of β-pinene resin, and stir while adding 1.5h until completely dissolved; add 0.5 part of sodium dodecylbenzenesulfonate, 0.9 part of sodium alcohol polyether sulfosuccinic acid monoester, 0.5 part of ammonium persulfate, 2 parts of maleic acid, Add 2 parts of methacrylic acid-β-hydroxypropyl ester to 20 parts of deionized water to obtain pre-emulsion A; Add 0.1 part of sodium to 15 parts of deionized water to obtain solution B; then add 20% of the mass fraction of pre-emulsion A to solution B, heat up to 70°C, and stir until the solution appears blue light, heat up to 83°C, and then within 2 hours Slowly add the remaining emulsion A dropwise and keep it warm for 2 hours. After the reaction is complete, cool down to 40°C, add ammonia water to adjust the pH to neutral, and cool down to room temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Peel force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com