Fluorine cluster-based metal organic framework MFOFs material with high stability, and application thereof

A high stability, organic framework technology, applied in other chemical processes, gas treatment, membrane technology, etc., can solve the problems of OMS not resistant to acid and alkali conditions, limited time length, difficult to use normally, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

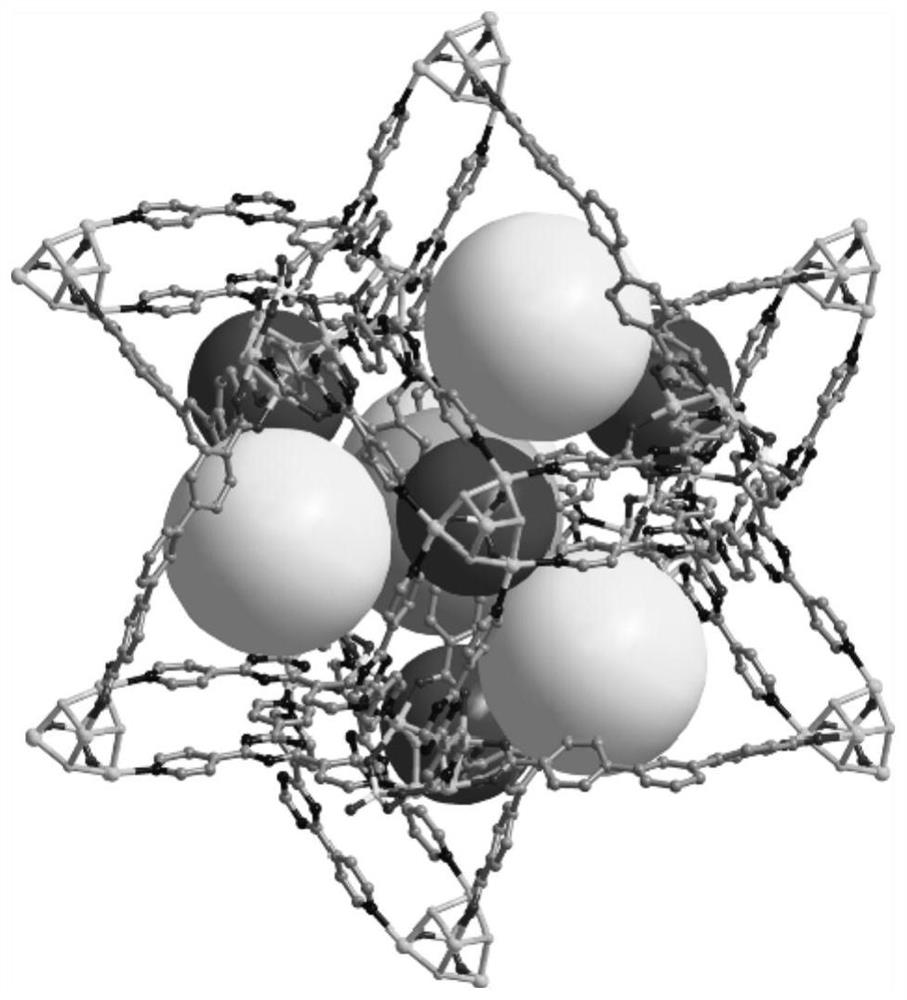

Image

Examples

Embodiment 1

[0043] Fluorine cluster-based MFOFs materials [Co 4 (μ 3 -F) 3 (μ 3 -SO 4 )(btb)(tpt) 2 ] The preparation method of (MFOF-1) crystal comprises the steps:

[0044] Weigh CoSO 4 ·6H 2 O (0.028g, 0.10mmol), 2,4,6-tris(4-pyridyl)-1,3,5-triazine (tpt) (0.016g, 0.050mmol), 1,3,5-tris( 4-carboxyphenyl)benzene (btb) (0.022g, 0.050mmol) was put into a 20mL glass bottle, and N,N dimethylacetamide (5mL) / methanol (5mL) / 1,4- Dioxane (1mL) solvent, sonicated for 30min, then added 100mL HBF 4 (tetrafluoroboric acid, 40wt% aqueous solution) for acidification; finally the mixed suspension was sealed and kept in a circulating oven at 100°C for 2 days, then collected, washed, and vacuum-dried to obtain the target product red octahedral crystal MFOF- 1.

[0045] The crystal MFOF-1 was soaked in acetone solvent, and the solvent was exchanged every 12 hours. After six exchanges, it was activated under vacuum at 120°C for 8 hours to obtain MFOF-1 crystals that could be used for adsorption ...

Embodiment 2

[0047] Fluorine cluster-based MFOFs materials [Ni 4 (μ 3 -F) 3 (μ 3 -SO 4 )(btb)(tpt) 2 ] The preparation method of (MFOF-2) crystal comprises the steps:

[0048] Weigh NiSO 4 ·7H 2 O (0.056g, 0.20mmol), 2,4,6-tris(4-pyridyl)-1,3,5-triazine (tpt) (0.031g, 0.10mmol), 1,3,5-tris( 4-carboxyphenyl)benzene (btb) (0.044g, 0.10mmol) was put into a 20mL glass bottle, and N,N dimethylformamide (5mL) / methanol (5mL) / 1,4- Dioxane (1 mL) solvent, sonicated for 30 min, then added 300 μL H 2 SiF 6 (fluorosilicic acid, 35wt% aqueous solution) for acidification; finally the mixed suspension was sealed and kept in a 120°C circulation oven for 7 days, then collected, washed, and vacuum-dried to obtain the target product green octahedral crystal MFOF- 2.

[0049] The crystal MFOF-2 was soaked in methanol solvent, and the solvent was exchanged every 12 hours. After six exchanges, it was activated under vacuum at 100°C for 15 hours to obtain the MFOF-2 crystal for adsorption test.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com