Proton exchange membrane, preparation method thereof and fuel cell

A proton exchange membrane and slurry technology, applied in fuel cells, circuits, electrical components, etc., can solve the problems of high swelling degree of proton exchange membrane, inhibition of swelling degree of proton exchange membrane, and inability to control swelling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

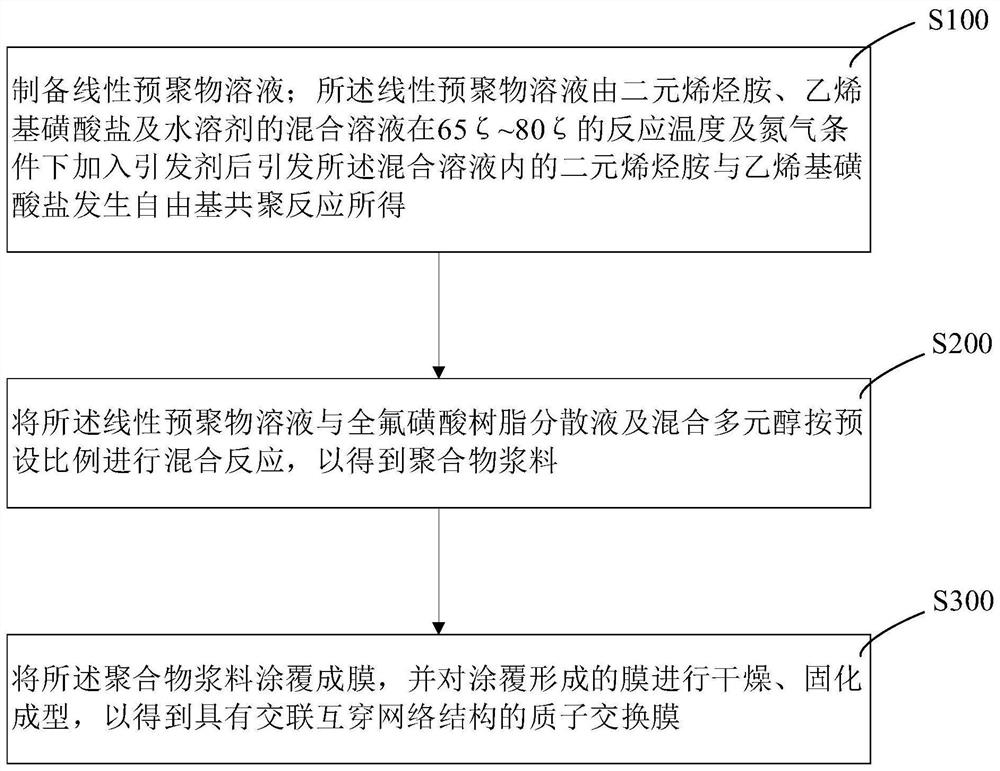

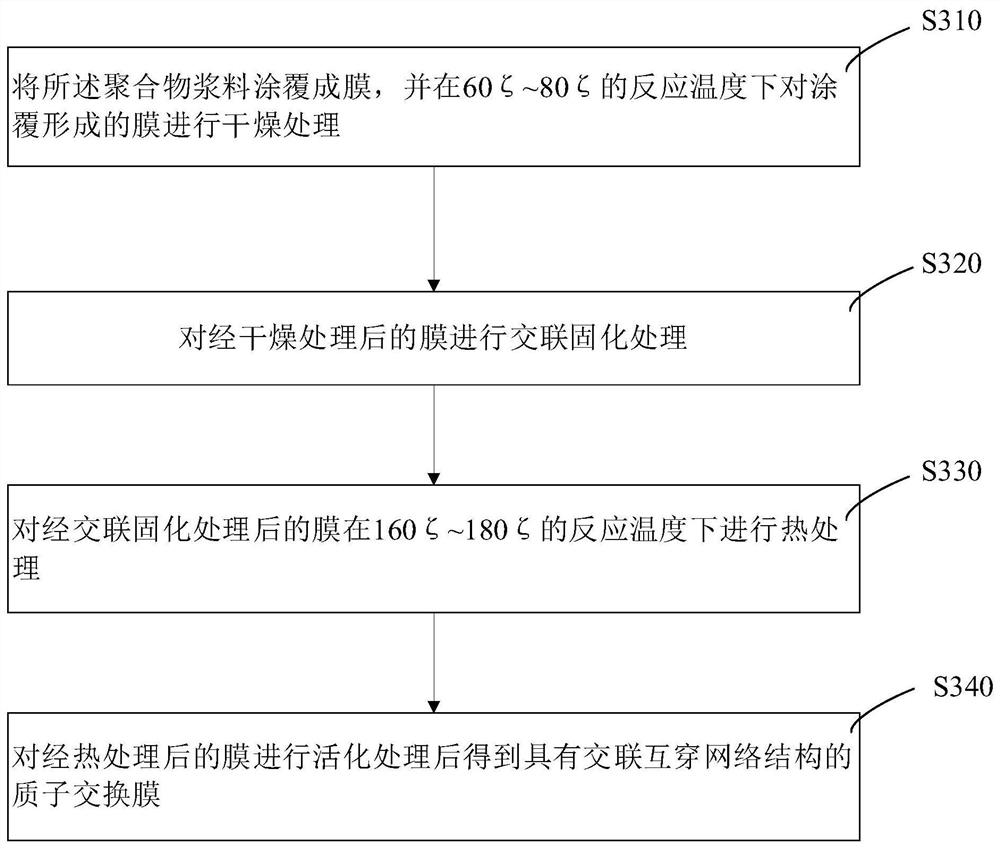

[0037] see figure 1 , the preparation method of the proton exchange membrane of a preferred embodiment of the present invention, comprises the steps:

[0038] Step S100: Prepare a linear prepolymer solution; the linear prepolymer solution is initiated by adding an initiator to a mixed solution of dibasic olefin amine, vinyl sulfonate and water solvent at a reaction temperature of 65°C-80°C and nitrogen gas It is obtained by free radical polymerization reaction of binary olefin amine and vinyl sulfonate in the mixed solution;

[0039] The synthetic reaction formula of above-mentioned linear prepolymer solution is shown in following formula (1):

[0040]

[0041]

[0042] Specifically, in the above formula (1) Refers to dibasic olefin amines; means vinyl sulfonate; Refers to the polymer molecule of the prepared linear prepolymer solution; K 2 S 2 o 8 as an initiator.

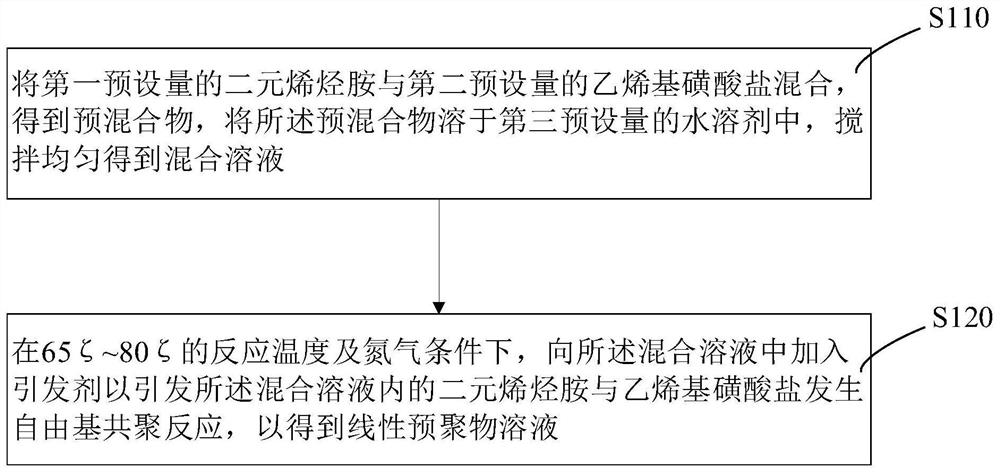

[0043] Step S100 specifically includes the following steps:

[0044] Step S110: Mix the first...

Embodiment 1

[0080] 1) Mix 15g of diallylamine and 5g of sodium styrene sulfonate to obtain a premixture, dissolve the premixture in 100mL of water solvent, and stir evenly to obtain a mixed solution;

[0081] 2) 0.5g sodium bisulfite and 1.2g potassium persulfate are mixed and dissolved in a water solvent, and stirred evenly to obtain an initiator;

[0082] 3) Under uniform stirring conditions, control the reaction temperature at 65°C-70°C and keep it under nitrogen, slowly add the initiator dropwise to the mixed solution to trigger the occurrence of dibasic olefin amine and vinyl sulfonate in the mixed solution Free radical polymerization, and then to obtain a linear prepolymer solution;

[0083] 4) Add 200mL of 1mol / L sulfuric acid solution to the linear prepolymer solution, and treat it with a dialysis bag with a molecular weight cut-off of 8000 to realize the acidification treatment of the linear prepolymer solution, and obtain the linear prepolymer solution after the acidification tr...

Embodiment 2

[0087] 1) Mix 12.5g of diallyl chloroacetamide with 3.6g of sodium allyl sulfonate to obtain a premixture, dissolve the premixture in 100mL of water solvent, and stir evenly to obtain a mixed solution;

[0088] 2) 0.5g sodium bisulfite and 1.2g potassium persulfate are mixed and dissolved in a water solvent, and stirred evenly to obtain an initiator;

[0089] 3) Under uniform stirring conditions, control the reaction temperature at 75°C-80°C and keep it under nitrogen, slowly add the initiator dropwise to the mixed solution to trigger the occurrence of dibasic olefin amine and vinyl sulfonate in the mixed solution Free radical polymerization, and then to obtain a linear prepolymer solution;

[0090] 4) Add 200mL of 1mol / L sulfuric acid solution to the linear prepolymer solution, and treat it with a dialysis bag with a molecular weight cut-off of 8000-14000 to realize the acidification treatment of the linear prepolymer solution, and obtain the linear prepolymer solution after ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com