Production process for improving comprehensive performance of aluminum alloy plate

An aluminum alloy sheet, comprehensive performance technology, applied in the field of aluminum alloy forming and heat treatment, can solve the problems of unmentioned material properties, reduced production efficiency, huge heating energy consumption, etc., to avoid the decline of grain refinement and eliminate residual Stress, the effect of shortening the cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

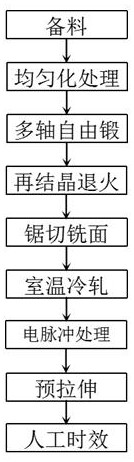

[0035] Such as figure 1 As shown, the scheme adopted in the production process of improving the comprehensive performance of aluminum alloy plate of the present invention is as follows:

[0036](1) Material preparation: saw the H112 state (hot-processed state) aluminum alloy square blank according to the process size requirements and cut it into a blank of 600 (± 5mm) × 600 (± 5mm) × 1000 (± 5mm), and use a marker pen on it before forging Marking on the end face of the billet to distinguish the three directions during forging and pre-stretching to obtain raw materials;

[0037] (2) Homogenization treatment: put the raw material obtained in step (1) into a furnace at room temperature, raise the temperature to 545±5°C according to the power and keep it warm for 6 hours, then raise the temperature to 580±5°C at a heating rate of 60°C / h and keep it warm for 0.5 hours, and then pass Cool to 480°C with the furnace for 3 hours, then hold for 0.5 hours, and ensure the uniformity of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com