A kind of vegetable oil-based hydrophilic polymer aqueous dispersion and its preparation method and application

A water-based polymer and oil-based pro-technology, applied in applications, ester copolymer adhesives, inks, etc., can solve the problems of low polymerization activity and inability to synthesize high polymers, so as to increase added value and reduce the pressure on petrochemical resources , Improve the effect of solid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

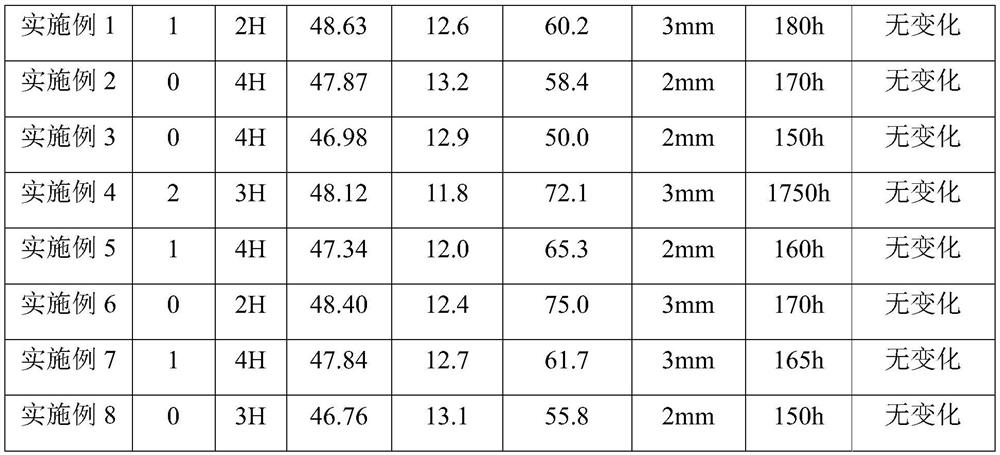

Examples

Embodiment 1

[0045] Add ricinoleic acid and thioglycolic acid to the quartz tube, add 3% of the weight of ricinoleic acid as photoinitiator 2-hydroxy-2-methyl-1-phenylacetone and butanone to react in a photochemical reactor, power 360W , the reaction was carried out for 4h, and the solvent was removed to obtain a castor oil-based polycarboxylic acid. The castor oil-based polycarboxylic acid is heated to 65°C, and isocyanoethyl acrylate is added. The molar ratio of the castor oil-based polycarboxylic acid and the isocyanoethyl acrylate is 1:1, and the reaction is carried out under stirring for 0.5 h to obtain the castor oil. Hemp oil-based hydrophilic monomer.

[0046] In the reactor, add ricinoleic acid, stir and heat up to 60 ° C, add 1% tertiary ammonium salt catalyst N,N-dimethylethanolamine of ricinoleic acid by weight, then heat up to 80 ° C and add dropwise containing 0.01% polymerization inhibitor The glycidyl methacrylate of hydroquinone was reacted for 1 h, and then the temperatu...

Embodiment 2

[0050] Add ricinoleic acid and mercaptopropionic acid into the quartz tube, add the photoinitiator 1-hydroxycyclohexyl phenyl ketone and butanone with 1% of the weight of ricinoleic acid, and react in a photochemical reactor with a power of 200W and react for 5h, The solvent is removed to obtain a castor oil-based polycarboxylic acid. The castor oil-based polycarboxylic acid was heated to 75°C, and isocyanoethyl methacrylate was added. The molar ratio of the castor oil-based polycarboxylic acid and the isocyanoethyl acrylate was 0.9:1, and the reaction was carried out for 1.5 h under stirring, that is, A castor oil-based hydrophilic monomer is obtained.

[0051] Add eleuic acid in the reaction kettle, stir and heat up to 50 ℃, add 1% tertiary ammonium salt catalyst N,N-dimethylethanolamine of eleuic acid by weight, then heat up to 70 ℃ and add dropwise a polymerization inhibitor containing 0.05% The glycidyl acrylate of benzoquinone was reacted for 2 hours, and then the tempe...

Embodiment 3

[0055] Add ricinoleic acid and mercaptosuccinic acid to the quartz tube, add 2% photoinitiator 2-methyl-2-(4-morpholinyl)-1-[4-(methylthio) by weight of ricinoleic acid ) Phenyl]-1-acetone and butanone were reacted in a photochemical reactor with a power of 300W for 5h, and the solvent was removed to obtain a castor oil-based polycarboxylic acid. The castor oil-based polycarboxylic acid is heated to 70 °C, and isocyanoethyl acrylate is added. The molar ratio of the castor oil-based polycarboxylic acid and the isocyanoethyl acrylate is 1:1, and the reaction is stirred for 1 hour to obtain castor oil. base hydrophilic monomer.

[0056] Add linoleic acid in the reaction kettle, stir and heat up to 70 ° C, add 1% tertiary ammonium salt catalyst N,N-dimethylethanolamine of linoleic acid by weight, then heat up to 90 ° C and add dropwise containing 0.1% polymerization inhibitor The hydroxyethyl methacrylate of methyl hydroquinone was reacted for 1 h, and then the temperature was ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pencil hardness | aaaaa | aaaaa |

| Impact resistance | aaaaa | aaaaa |

| Flexibility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com