Toughening column type porcelain insulator and preparation method thereof

A technology of porcelain insulators and insulators, applied in the field of toughened pillar porcelain insulators and their preparation, can solve problems such as poor toughness and mechanical properties, paralysis of railway lines, potential safety hazards, etc., and achieve improved mechanical strength, improved insulation performance, and improved strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

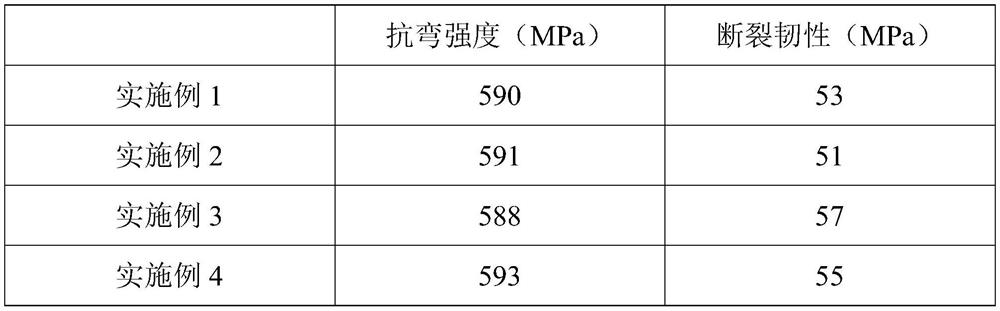

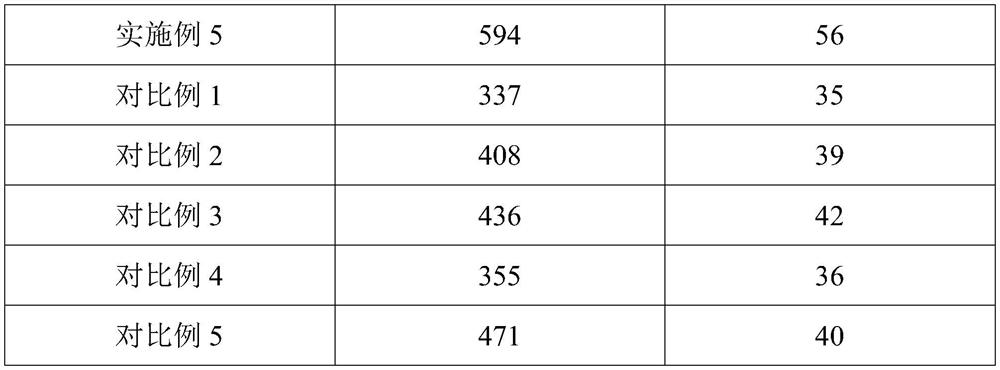

Examples

Embodiment 1

[0036] A toughened pillar porcelain insulator in this embodiment includes an insulator body and an insulating layer, wherein the insulator body is fired from a base material, a filling material and a pore-forming agent. The base material includes the following raw materials in parts by weight: 15 parts of bauxite, 20 parts of feldspar, 12 parts of kaolin, 12 parts of alumina, 12 parts of Hubei mud, 5 parts of molecular sieve, 5 parts of boric acid, 5 parts of talc, 5 parts of zirconium silicate 3 parts, 3 parts of zinc oxide, 0.5 part of water reducer, water reducer includes the following raw materials in parts by weight: 8 parts of polymethylene phosphate, 18 parts of choline glycinate ionic liquid, 5 parts of sodium polyacrylate, 1 part of sodium chloride share. The filler includes the following raw materials in parts by weight: 8 parts of zirconia composite nanoparticles, 12 parts of calcium phosphate nanofibers, 5 parts of carbon fibers, and 3 parts of polyethylene, wherei...

Embodiment 2

[0047] A toughened column type porcelain insulator in this embodiment includes an insulator body and an insulating layer, wherein: the insulator body is fired from a base material, a filler and a pore-forming agent, and the base material includes the following raw materials in parts by weight: aluminum alum 25 parts of soil, 12 parts of feldspar, 20 parts of kaolin, 20 parts of alumina, 20 parts of Hubei mud, 15 parts of molecular sieve, 15 parts of boric acid, 12 parts of talc, 12 parts of zirconium silicate, 8 parts of zinc oxide, 2.5 parts of water reducer The water reducer includes the following raw materials in parts by weight: 18 parts of polymethylene phosphate, 8 parts of choline co-acid salt ionic liquid, 15 parts of polyacrylate, and 5 parts of sodium chloride. The filler includes the following raw materials in parts by weight: 15 parts of zirconia composite nanoparticles, 5 parts of calcium phosphate nanofibers, 12 parts of carbon fibers, 4 parts of polypropylene, an...

Embodiment 3

[0058] A toughened column type porcelain insulator in this embodiment includes an insulator body and an insulating layer, wherein: the insulator body is fired from a base material, a filler and a pore-forming agent, and the base material includes the following raw materials in parts by weight: aluminum alum 20 parts of soil, 15 parts of feldspar, 15 parts of kaolin, 18 parts of alumina, 18 parts of Hubei mud, 10 parts of molecular sieve, 10 parts of boric acid, 10 parts of talc, 8 parts of zirconium silicate, 5 parts of zinc oxide, 1.5 parts of water reducer Among them, the water reducer includes 15 parts of polymethylene phosphate, 15 parts of choline L-alanine salt ionic liquid, 10 parts of polyacrylate, and 2 parts of sodium chloride. The filler includes the following raw materials in parts by weight: 10 parts of zirconia composite nanoparticles, 7 parts of calcium phosphate nanofibers, 8 parts of carbon fibers, 2 parts of polystyrene, 2 parts of polyamide, and 2 parts of ru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com