Platinum-copper alloy/chloride ion transporter composite tumor treatment preparation and preparation method and application thereof

A platinum-copper alloy, tumor treatment technology, used in anti-tumor drugs, drug combinations, pharmaceutical formulations, etc., can solve the problems of low chloride ion concentration, poor tumor treatment effect, and low production of reactive oxygen species.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] This embodiment provides a method for preparing a platinum-copper alloy / chloride ion transporter composite tumor treatment preparation, in which the chloride ion transporter is loaded onto the surface of platinum-copper alloy nanoparticles through electrostatic interaction.

[0051] Wherein, the platinum-copper alloy nanoparticles are prepared by a solvothermal method, and polyethylene glycol PEG is used as a stabilizer. Specifically, the preparation method of the platinum-copper alloy nanoparticles is as follows:

[0052] Dissolve 10 mg of platinum acetylacetonate and 100 mg of copper acetylacetonate in 10 mL of oleylamine, and stir magnetically for 2 hours to obtain solution 1;

[0053] Dissolve 500mg cetyltrimethylammonium bromide CTAB in 10mL oleylamine to obtain solution 2;

[0054] Mix solution 2 and solution 1 at a volume ratio of 1:2, transfer to a 50mL stainless steel reaction kettle after mixing, seal it, and put the reaction kettle in a 150°C oven for 24 hour...

Embodiment 2

[0064] The preparation method of the platinum-copper alloy nanoparticles is as follows:

[0065] Dissolve 60 mg of platinum acetylacetonate and 200 mg of copper acetylacetonate in 10 mL of oleylamine, and stir magnetically for 2 hours to obtain solution 1;

[0066] Dissolve 1000mg cetyltrimethylammonium bromide CTAB in 10mL oleylamine to obtain solution 2;

[0067] Mix solution 2 and solution 1 at a volume ratio of 2:1, transfer to a 50mL stainless steel reaction kettle after mixing, seal it, and put the reaction kettle in an oven at 200°C for 72 hours;

[0068] After the reaction was completed, it was naturally cooled to room temperature and taken out, the reaction product was centrifuged at 12000 rpm, washed several times with acetone, and then centrifuged to obtain the centrifuged product;

[0069] The centrifuged product and polyethylene glycol PEG were dissolved in water according to the mass ratio of 1:10, stirred for 48 hours, and the platinum-copper alloy nanoparticle...

Embodiment 3

[0077] Platinum-copper alloy nanoparticles prepared by solvothermal method with PEG as a stabilizer

[0078] Weigh 41.4 mg of platinum acetylacetonate and 138.4 mg of copper acetylacetonate and dissolve in 10 mL of oleylamine (solution 1), and stir magnetically for 2 hours. At the same time, 700 mg of CTAB was weighed and dissolved in 10 mL of oleylamine (solution 2). Then, solution 2 was transferred to solution 1, and the mixed solution was transferred to a 50 mL stainless steel reaction vessel and sealed. Put the reaction kettle into an oven at 170°C for 48 hours. After natural cooling to room temperature, the reaction product was taken out by centrifugation at 12,000 rpm, washed three times with acetone, and the obtained platinum-copper alloy nanoparticles were centrifuged.

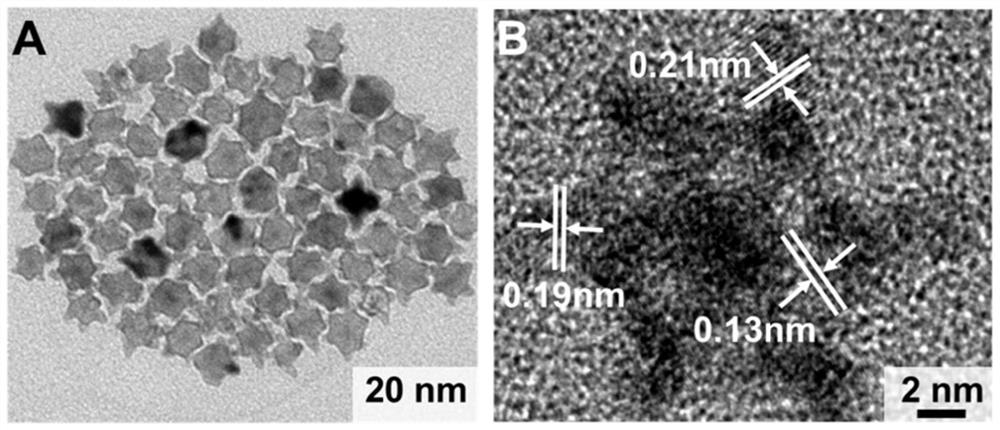

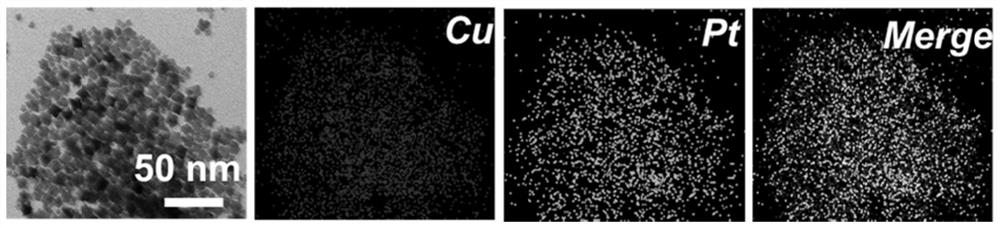

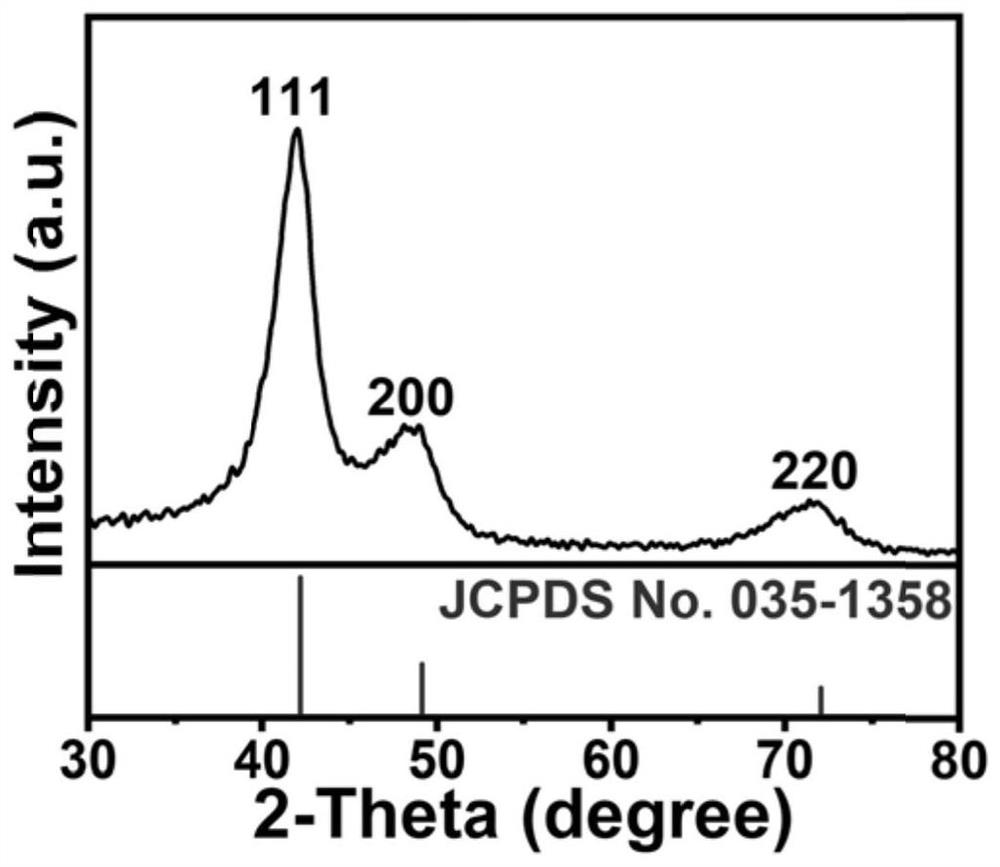

[0079] figure 1 It is an electron microscope picture of platinum-copper alloy nanoparticles in the embodiment of the present invention, wherein (A) is a transmission electron microscope picture, fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com