Prediction method of calcium yield during calcium processing based on deep neural network

A technology of deep neural network and prediction method is applied in the field of yield prediction, which can solve the problems of inability to predict the yield of calcium treatment process, control of calcium content within a certain range, and unstable control of calcium content, so as to improve production efficiency. And the effect of product quality, reduction of production cost, and reduction of nozzle nodules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Exemplary embodiments, features, and aspects of the present invention will be described in detail below with reference to the accompanying drawings. The same reference numbers in the figures indicate functionally identical or similar elements. While various aspects of the embodiments are shown in drawings, the drawings are not necessarily drawn to scale unless specifically indicated.

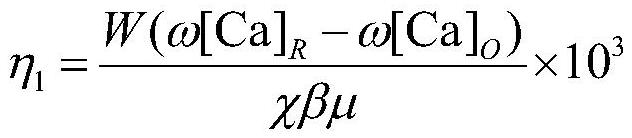

[0041] According to an embodiment of the present invention, a method for predicting the yield of calcium in a molten steel calcium treatment process based on a deep neural network is provided.

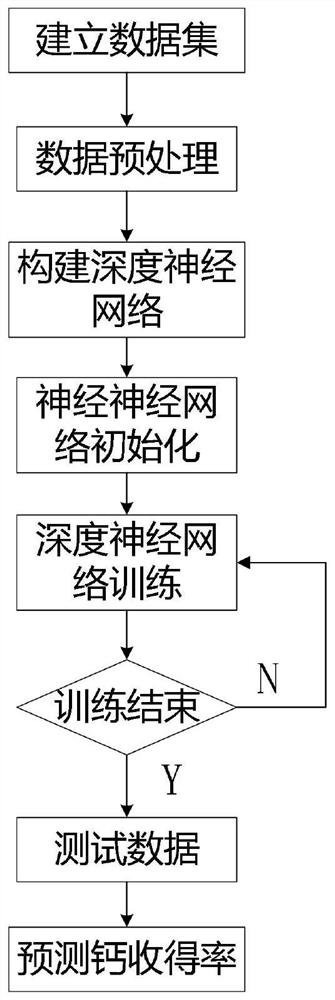

[0042] Such as figure 1 As shown, the method for predicting the yield of calcium in the calcium processing process based on the deep neural network according to the embodiment of the present invention comprises the following steps:

[0043]Step 1: Obtain in advance the production and operation data of steel grades that have adopted calcium treatment technology in a domestic factory in the past y...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com