Preparation method and processing equipment of bio-based modified low-heat-generation reinforcing agent

A processing equipment and bio-based technology, applied to chemical instruments and methods, mixers with rotating stirring devices, mixers, etc., can solve problems affecting product performance, difficulty in eating powder, vulcanization effects, etc., to improve efficiency and quality , Good processing technology, reduce the effect of compression heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

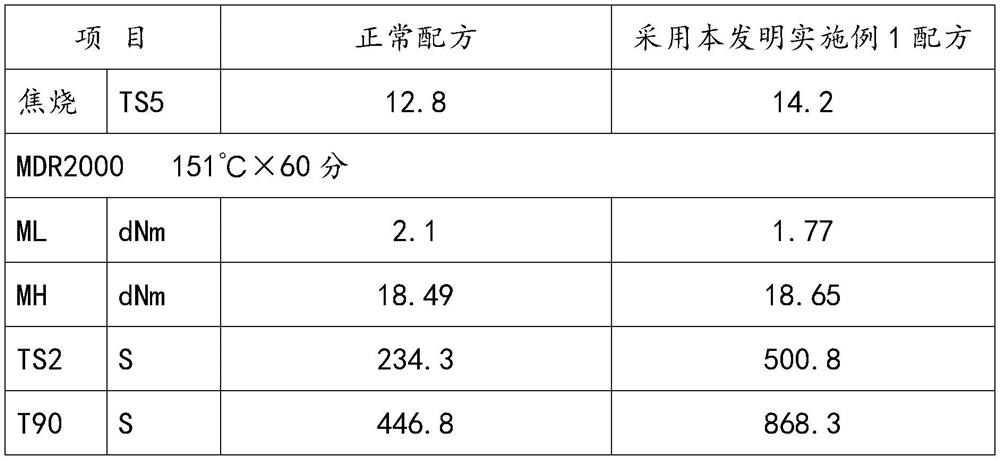

Embodiment 1

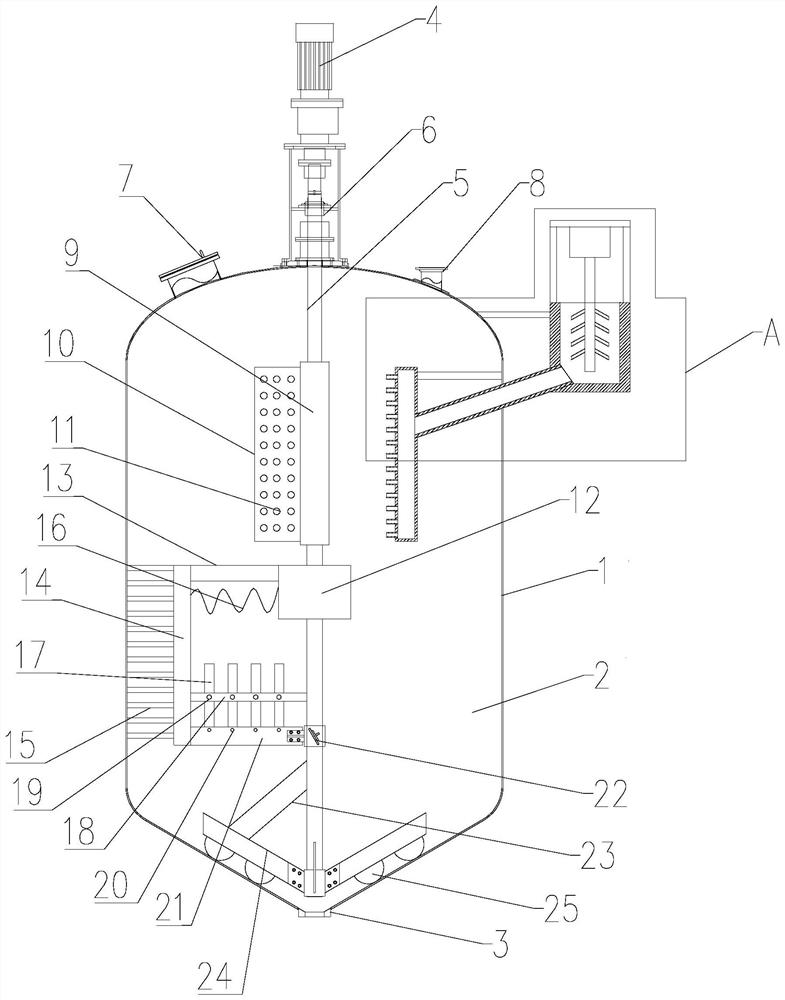

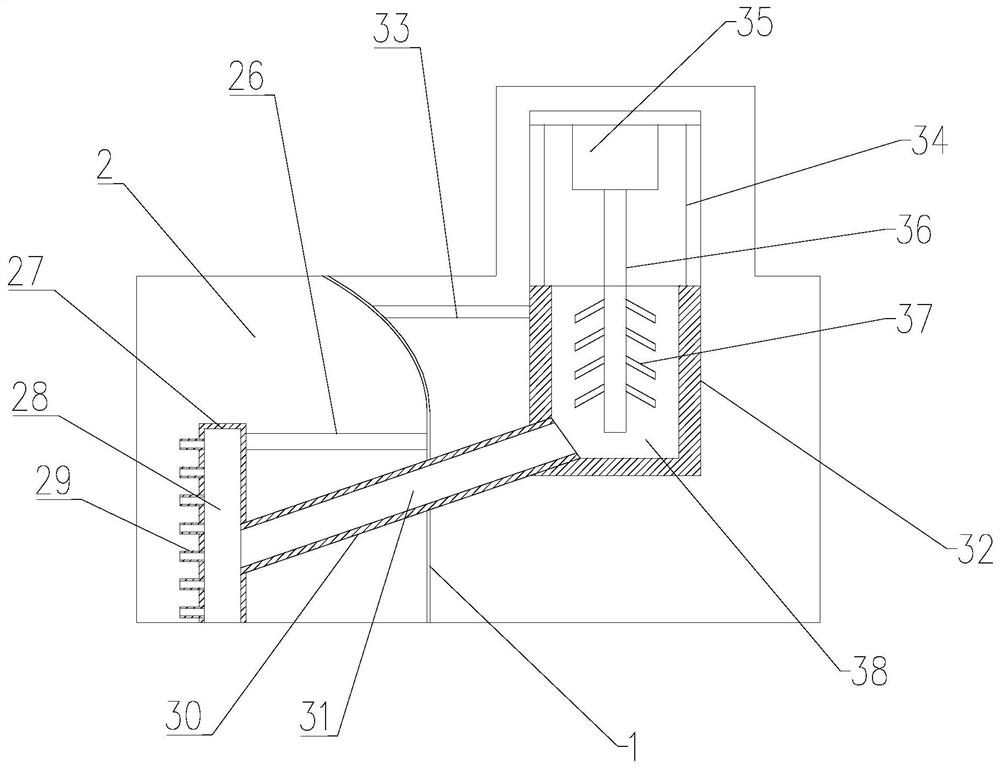

[0033] The embodiment of the present invention proposes a preparation method of a bio-based modified low heat generation enhancer, comprising the following steps:

[0034]S1, the non-metallic mineral material is pounded and desanded and ground to a particle size of 10 μm and added to the first stirred tank, and then added to the first stirred tank with a mass fraction of 10% sodium chloride and a mass fraction of 20% calcium carbonate Solution, stirred at 750r / min for 30min, then heated to 85°C and kept for 13min, stirred at 2000r / min for 55min, added silane coupling agent Si-69 and stearic acid, kept for 10min, continued high-speed stirring and heated to 100 ℃, add zinc oxide and phenolic resin, and keep for 10 minutes to obtain modified kaolin;

[0035] S2. Put the modified biomass, lignin, petroleum resin and urotropine into the second stirring tank, stir and mix to obtain a bio-based modified low-heat enhancer.

[0036] In this embodiment, in S2, the petroleum resin is Co...

Embodiment 2

[0046] Different from Example 1, the embodiment of the present invention proposes a preparation method of a bio-based modified low heat generation enhancer, including the following steps:

[0047] S1, the non-metallic mineral material is pounded and desanded and ground to a particle size of 15 μm and added to the first stirred tank, and then added to the first stirred tank with a mass fraction of 10% sodium chloride and a mass fraction of 20% calcium carbonate Solution, stirred at 650r / min for 40min, then heated to 80°C and kept for 15min, stirred at 1500r / min for 60min, added silane coupling agent Si-69 and stearic acid, kept for 15min, continued high-speed stirring and heated to 95 ℃, add zinc oxide and phenolic resin, and keep for 15 minutes to obtain modified kaolin;

[0048] S2. Put the modified biomass, lignin, petroleum resin and urotropine into the second stirring tank, stir and mix to obtain a bio-based modified low-heat enhancer.

[0049] In this embodiment, in S2, ...

Embodiment 3

[0053] Different from Example 1, the embodiment of the present invention proposes a preparation method of a bio-based modified low heat generation enhancer, including the following steps:

[0054] S1, the non-metallic mineral material is pounded and desanded and ground to a particle size of 5 μm and added to the first stirred tank, and then added to the first stirred tank with a mass fraction of 10% sodium chloride and a mass fraction of 20% calcium carbonate Solution, stirred at 850r / min for 20min, then heated to 90°C and kept for 10min, stirred at 2500r / min for 50min, added silane coupling agent Si-69 and stearic acid, kept for 5min, continued high-speed stirring and raised to 105 ℃, add zinc oxide and phenolic resin, and keep for 5 minutes to obtain modified kaolin;

[0055] S2. Put the modified biomass, lignin, petroleum resin and urotropine into the second stirring tank, stir and mix to obtain a bio-based modified low-heat enhancer.

[0056] In this embodiment, in S2, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com