Microwave dielectric ceramic material, preparation method and application

A technology of microwave dielectric ceramics and ceramics, which is applied in the field of ceramic materials, can solve the problems of weak product stability and poor thermal shock resistance, and achieve the effects of low raw material prices, improved thermal shock resistance, and high thermal shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

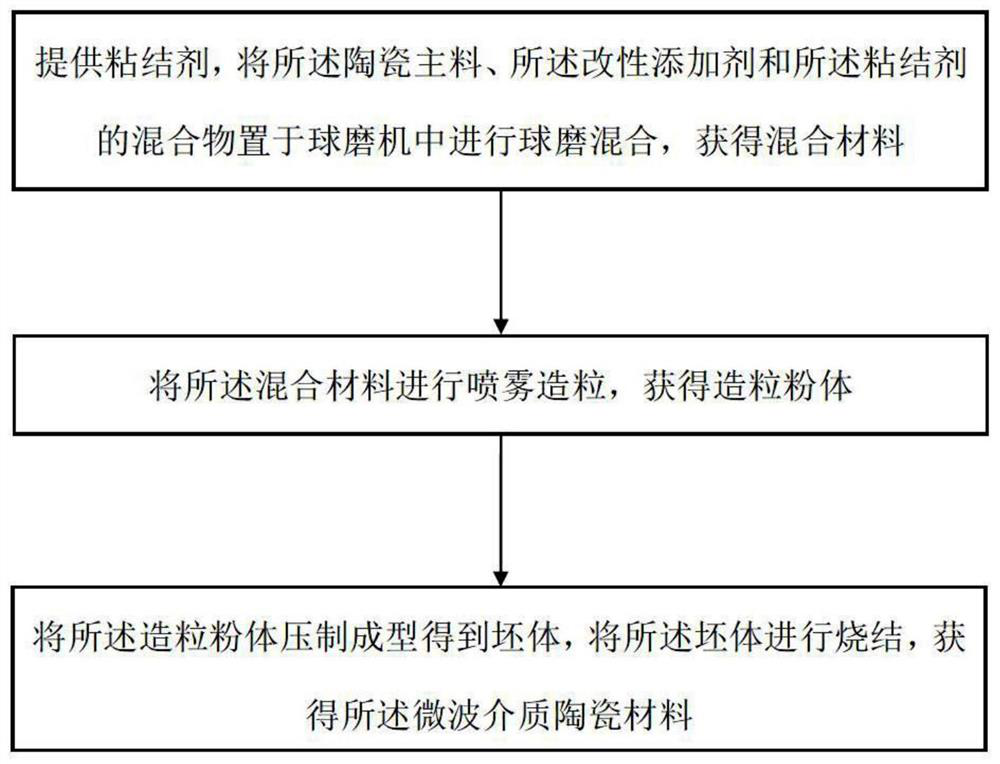

[0088] The preparation method of the microwave dielectric ceramic material provided by the invention has the advantages of low raw material price, simple and easy process circuit, and is suitable for large-scale industrial production.

[0089] Optionally, the mixing method includes ball milling and / or sand milling.

[0090] In some embodiments of the present invention, the mixture of the ceramic main material and the binder is placed in a ball mill for ball milling and mixing, the rotating speed of the ball milling is 200r / min-400r / min, and the time of ball milling is 3h-8h to obtain a mixed slurry material.

[0091] In some embodiments of the present invention, the binder is typically but not limited to polyvinyl alcohol, polyacrylic acid.

[0092] Preferably, a granulation process after mixing is also included.

[0093] In some embodiments of the present invention, the mixed slurry is subjected to spray granulation to obtain granulated powder. The average particle diamete...

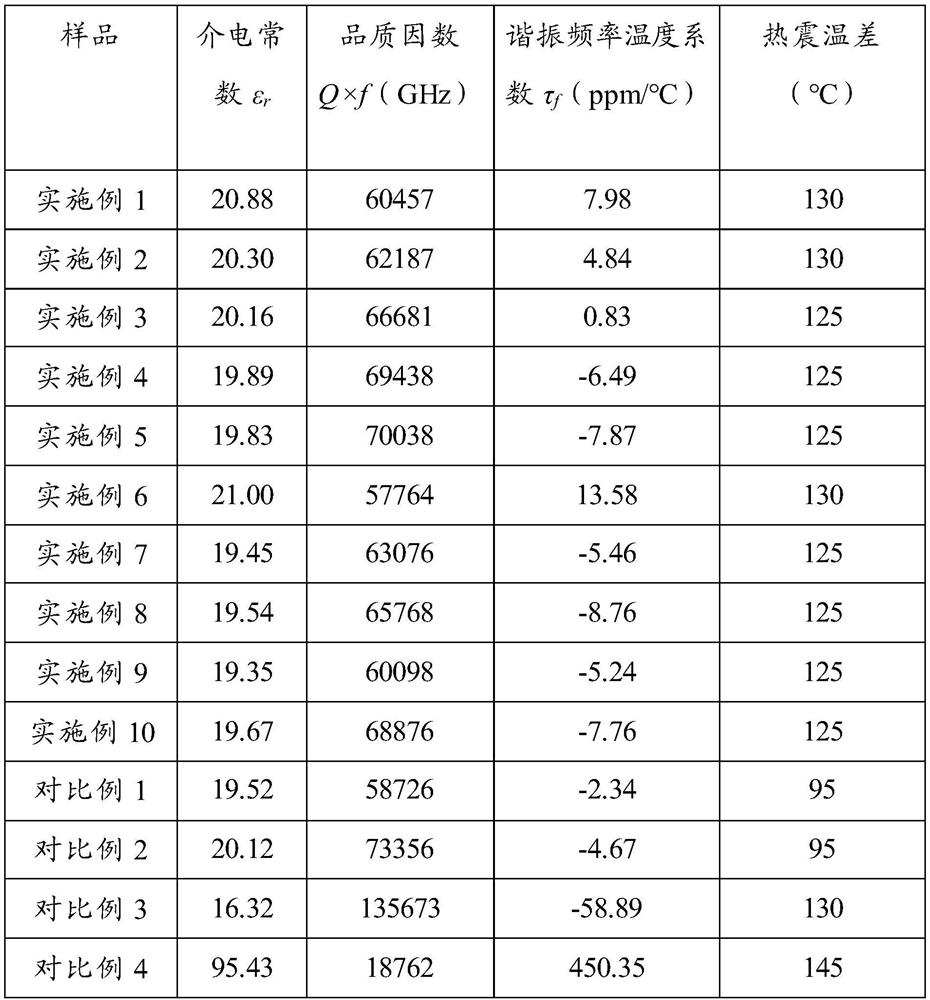

Embodiment 1

[0135] This embodiment provides a microwave dielectric ceramic material, including ceramic main materials and additives.

[0136] The ceramic main material is composed of 77wt% MgTiO 3 , 9.0wt% (Ca 0.8 Sr 0.2 )TiO 3 and 14wt% (Mg 0.5 Zn 0.5 )Al 2 o 4 constitute.

[0137] The mass of the additive is 1% of the mass of the ceramic main material. Among them, the first additive is SiO 2 , the quality is 0.5% of the mass of ceramic main material; the second additive is CeO 2 , the mass is 0.2% of the mass of the ceramic main material; the third additive is BN, and the mass is 0.3% of the mass of the ceramic main material.

[0138] The preparation process of the microwave dielectric ceramic material is as follows: figure 1 As shown, the specific steps are as follows:

[0139] (1) Preparation of MgTiO 3 : MgO and TiO 2 According to the molar ratio of 1:1, TiO 2 Consisting of 14% by mass anatase TiO 2 and rutile TiO with a mass ratio of 86% 2 constitute. After batchin...

Embodiment 2

[0144] This embodiment provides a microwave dielectric ceramic material, including ceramic main materials and additives.

[0145] The ceramic main material is composed of 79wt% MgTiO 3 , 8.0wt% (Ca 0.8 Sr 0.2 )TiO 3 and 13wt% (Mg 0.5 Zn 0.5 )Al 2 o 4 constitute.

[0146] The mass of the additive is 1.5% of the mass of the ceramic main material. Among them, the first additive is SiO 2 , the quality is 1% of the mass of ceramic main material; the second additive is Nd 2 o 3 , the mass is 0.2% of the mass of the ceramic main material; the third additive is BN, and the mass is 0.3% of the mass of the ceramic main material.

[0147] The preparation steps (1)-(3) of the microwave dielectric ceramic material are the same as (1)-(3) in Embodiment 1, and will not be repeated here.

[0148] (4) Mix ceramic main ingredients: mix ceramic main ingredients, first additive, second additive, third additive and binder polyvinyl alcohol by ball milling, the speed of ball milling is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality factor | aaaaa | aaaaa |

| resonant frequency temperature coefficient | aaaaa | aaaaa |

| resonant frequency temperature coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com