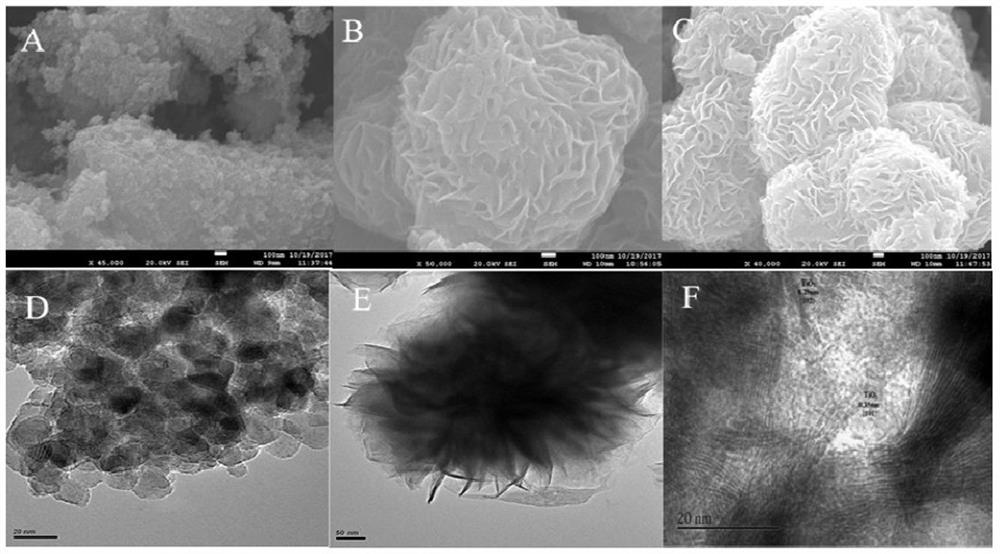

Nano flower-like composite catalyst and its preparation method and application

A composite catalyst, nanoflower technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as short process flow, and achieve the effects of short process flow, short time and high preparation yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Prepare a kind of nano flower shape composite catalyst, comprises the following steps:

[0059] (1) Mix 10 ml of butyl titanate, 35 ml of absolute ethanol, 4 ml of glacial acetic acid, 3 mmol of sodium molybdate, 6 mmol of thioacetamide and 30 ml of oleic acid to obtain a mixed reaction solution, and additional Adjust the pH with glacial acetic acid so that the pH of the mixed reaction solution is 3.0;

[0060](2) Transfer the mixed reaction solution obtained in step (1) to a Teflon reactor, and place it in a muffle furnace for closed reaction. The reaction temperature is 200°C, and the reaction time is 25 h;

[0061] (3) Cool the reaction kettle to room temperature, take out the reaction solution, separate the black solid by high-speed centrifugation at 13,000 r / min, wash it with pure water, put the black solid in a drying oven, and dry at a constant temperature of 105±5°C for 10 h;

[0062] (4) Put the dried solid in a muffle furnace, keep the volume content of oxyge...

Embodiment 2

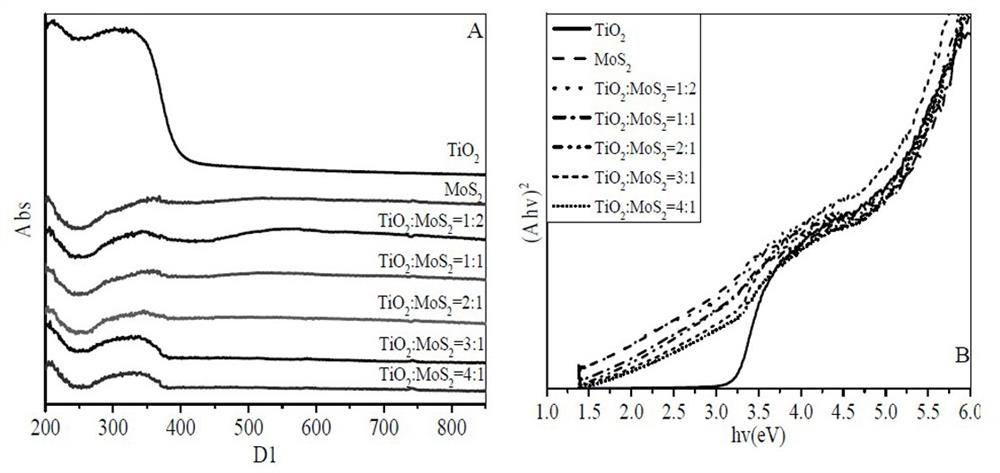

[0064] Embodiment 2 is basically the same as Embodiment 1, the only difference is:

[0065] Adjust the raw material addition amount in embodiment 2, make the TiO in the catalyst that embodiment 2 prepares 2 with MoS 2 The molar ratio is 1:2.

Embodiment 3

[0067] Embodiment 3 is basically the same as Embodiment 1, the only difference is:

[0068] Adjust the amount of raw material added in embodiment 3, so that in the catalyst prepared in embodiment 3, TiO 2 with MoS 2 The molar ratio is 1:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com