Industrialized preparation technology of nm-class silver powder

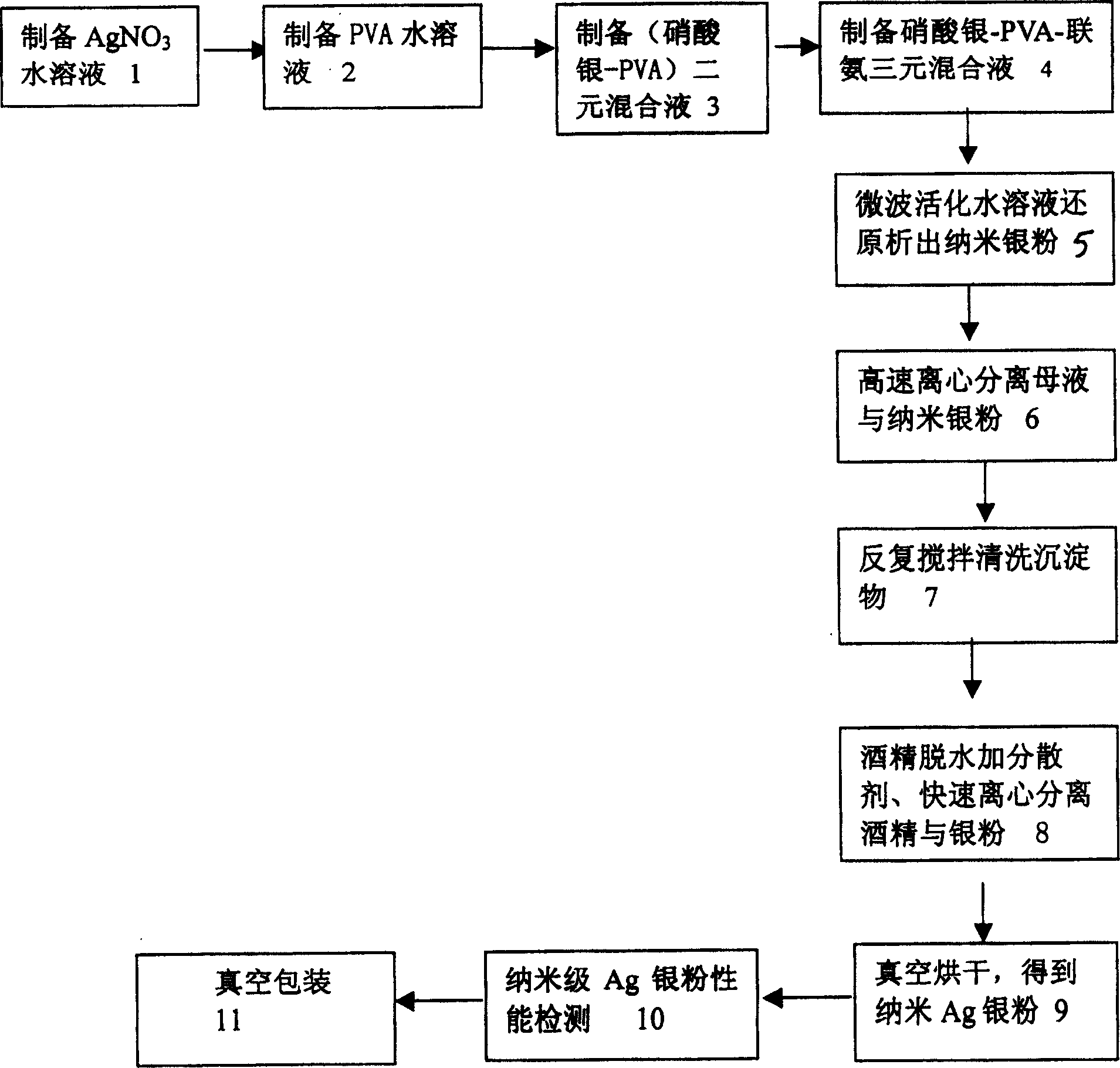

A nano-level, silver powder technology is applied in the industrial preparation of nano-level silver powder and the industrial production field of nano-level silver powder, which can solve the problems of difficult cleaning and separation of slurry, shortening solution reduction reaction time, etc., and achieves simple equipment, saving reduction and precipitation. time, the effect of increasing the level of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: When preparing 1kg nano Ag powder, it should be completed according to the following steps.

[0036] 1. Weigh 1.57kg AgNO 3 Powder, by AgNO 3 :H 2 Add O=85:1000 mass ratio to 18.53Kg distilled water, heat to 80°C, make it fully dissolved, and prepare 20.1Kg AgNO 3 aqueous solution;

[0037] 2. Press PVA: H 2 O=2:100 (mass ratio), add 0.197Kg PVA to 9.85Kg distilled water, heat and stir at 100°C until completely dissolved, that is, prepare 10.05Kg PVA release agent solution for later use.

[0038] 3. Prepare (silver nitrate-PVA) binary mixture.

[0039] In the above 20.1Kg AgNO 3 In aqueous solution, according to PVA solution: AgNO 3 Solution=1:2 (mass ratio) Add 10.05Kg of PVA aqueous solution to prepare 30.15Kg (silver nitrate-PVA) binary mixed solution.

[0040] 4. Preparation of silver nitrate-hydrazine-PVA ternary mixed solution

[0041] Press N 2 h 4 ·H 2 O: AgNO 3 =1:1.7 mass ratio, 0.93Kg N 2 h 4 ·H 2 The O solution was slowly poured...

Embodiment 2

[0055] Embodiment 2: when preparing 500g nanometer Ag powder, should complete according to the following steps

[0056] 1. Weigh 0.785kg AgNO 3 powder, the AgNO 3 Press AgNO 3 :H 2 Add O=85:1000 mass ratio to 9.265Kg distilled water, heat to 60°C, stir vigorously, and prepare 10.05Kg AgNO 3 aqueous solution;

[0057] 2. Prepare PVA solution, press PVA:H 2 O=2:100 (mass ratio) Weigh 0.099Kg of PVA powder and 4.925Kg of distilled water, heat and stir at 90°C until completely dissolved, and prepare 5.024Kg of PVA release agent solution for later use.

[0058] 3. Preparation of (silver nitrate-PVA) binary mixture

[0059] Above-mentioned 1, 2 two kinds of solutions are mixed in total 15.074Kg to make binary mixed liquid, and concrete operation is exactly the same as (3,) among the embodiment 1.

[0060] 4. Preparation of silver nitrate-hydrazine-PVA ternary mixed solution

[0061] It is substantially the same as (4,) in Example 1. The difference is that 0.465kg N 2 h 4 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com