Technique and facility for decomposing monazite rare earth ore through alkaline method

An alkaline decomposition and monazite technology, applied in the direction of improving process efficiency, can solve the problems of low decomposition rate of monazite, large power consumption for heating oil heating, and unsealed system production, so as to avoid insufficient or excessive decomposition. Long-term decomposition, providing equipment use efficiency, and solving the effect of precise batching problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

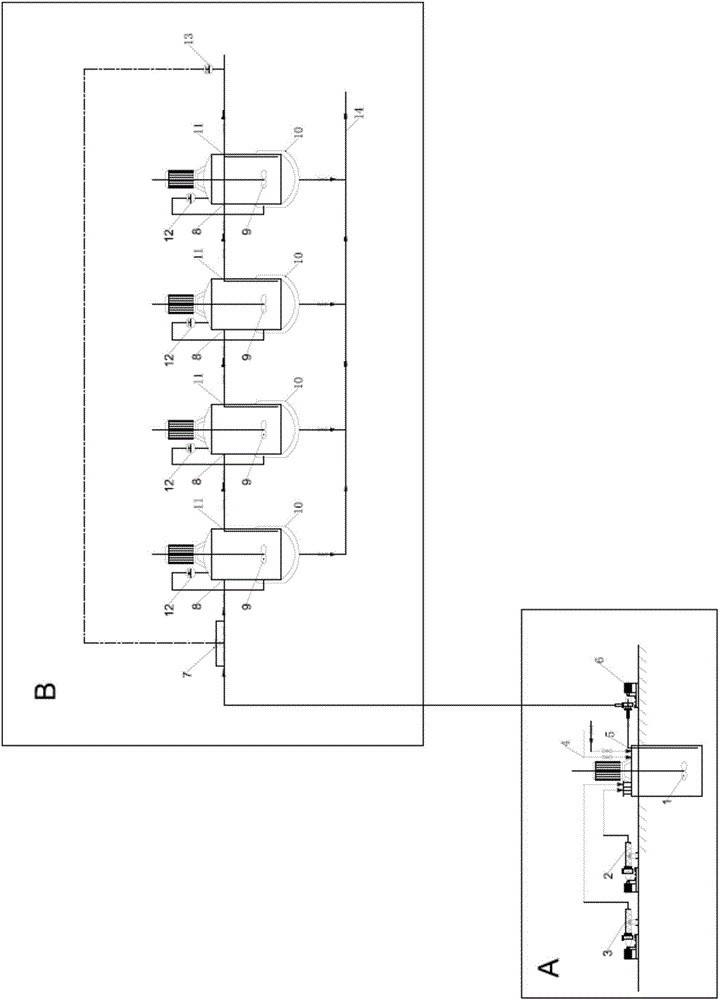

Image

Examples

Embodiment 1

[0033] Add -325 mesh 51.2% monazite (ThO2 content 3.9%) from the batching part, and add alkali at the solid and liquid caustic feed ports to adjust its concentration to 45% lye The ratio of slurry to solid is 3:1. After stirring and mixing, the slurry passes through a 4-stage far-infrared heating reaction tank in turn and reacts at 140 °C. The slurry feeding amount and feeding speed are controlled by monitoring the specific gravity of the slurry and controlling the slurry pump. , After the slurry stays in the reaction tank for 11.5 hours, the decomposed slurry is continuously and stably obtained from the final discharge port. After filtration and washing, the decomposition rate of concentrate is 97.7%.

Embodiment 2

[0038] Add -325 mesh 30% monazite (ThO2 content 3.1%) from the batching part, and add alkali to the solid and liquid alkali feed ports to adjust its concentration to 65% lye The slurry-to-solid ratio is 1.5:1. After stirring and mixing, the slurry passes through the 4-stage far-infrared heating reaction tank in turn and reacts at 80 °C. The slurry feeding amount and feeding speed are controlled by monitoring the specific gravity of the slurry and controlling the slurry pump. , After the slurry stays in the reaction tank for 12.5 hours, the decomposed slurry is continuously and stably obtained from the final discharge port. After filtration and washing, the decomposition rate of concentrate is 96.5%.

Embodiment 3

[0040] Add -325 mesh 51.3% monazite (ThO2 content 3.9%) from the batching part, and add alkali into the solid and liquid alkali feed ports to adjust its concentration to 50% lye The ratio of slurry to solid is 3:1. After stirring and mixing, the slurry passes through a 4-stage far-infrared heating reaction tank in turn and reacts at 200 °C. The slurry feeding amount and feeding speed are controlled by monitoring the specific gravity of the slurry and controlling the slurry pump. , After the slurry stays in the reaction tank for 11.0 hours, the decomposed slurry is continuously and stably obtained from the final discharge port. After filtration and washing, the decomposition rate of concentrate is 98.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com