Preparation method of deposited, ventilated and reduced nanometer-level silver powder

A nano-silver powder and nano-technology, applied in the field of industrial scale production of nano-scale silver powder, can solve the difficulty of separation of mother liquor and silver particles and repeated cleaning and filtration, long time, generally 1~2 hours, sometimes up to 4 hours, not large Large-scale investment in industrial production and other issues to achieve the effects of easy continuous automatic control, saving precipitation and reduction time, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

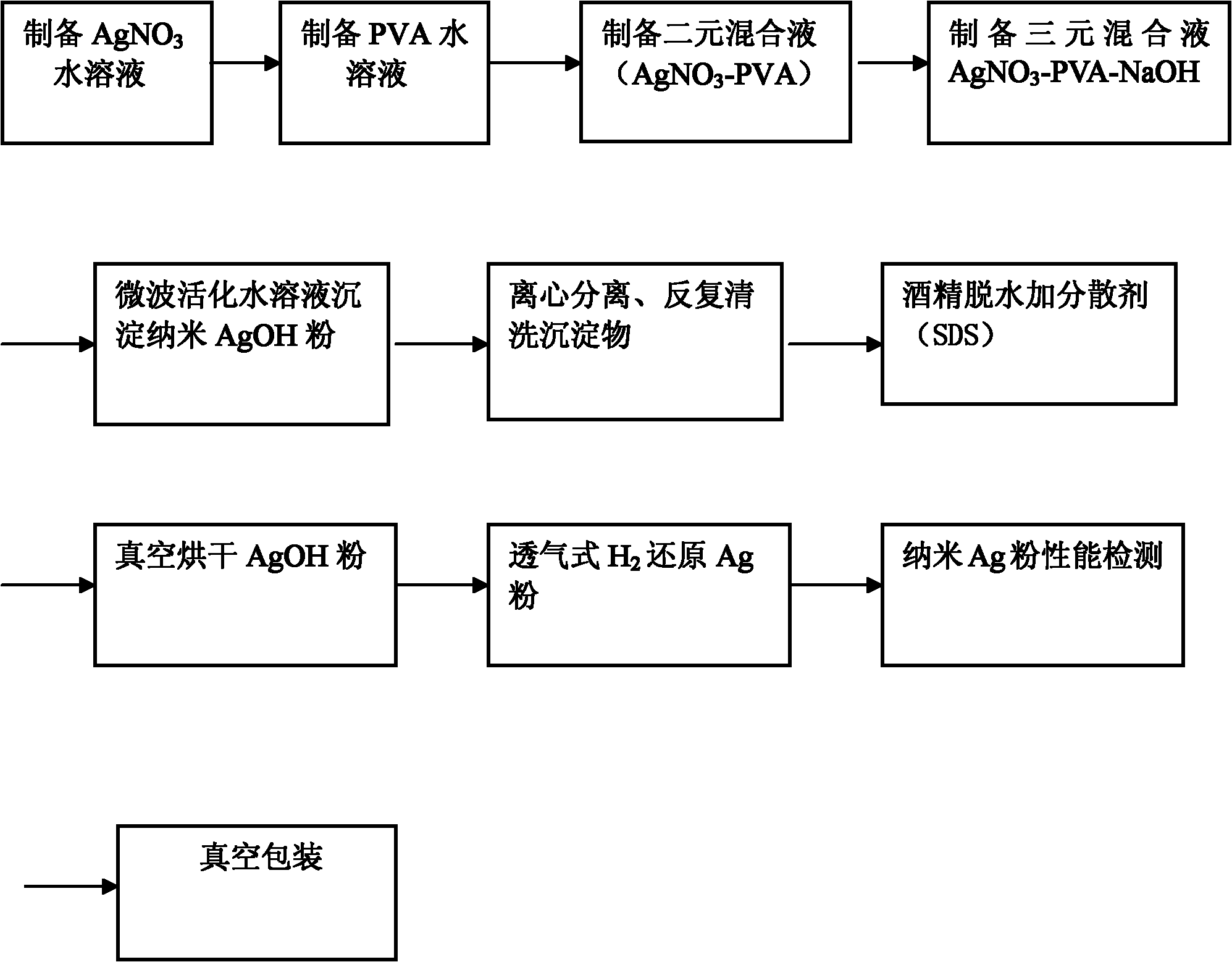

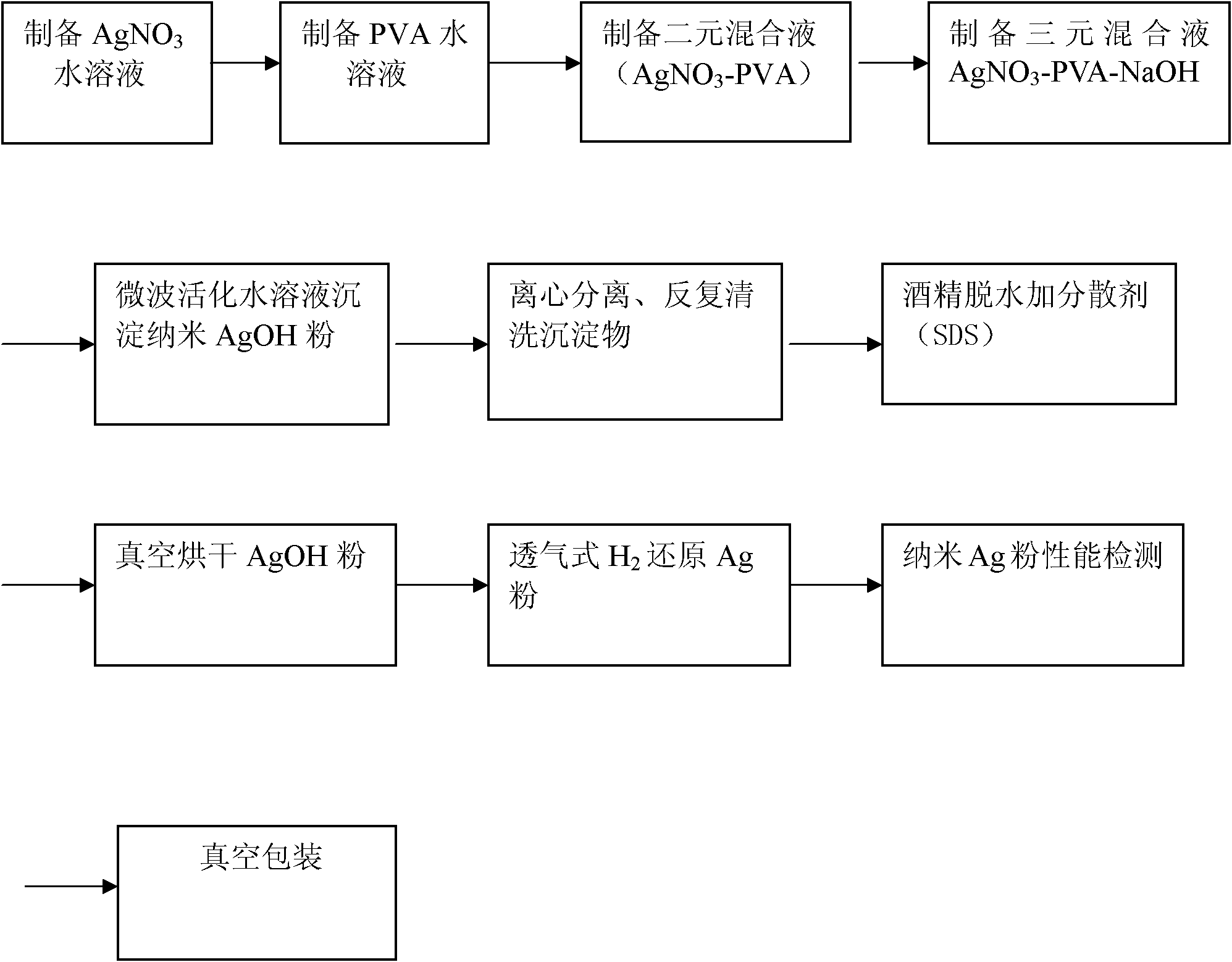

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: When preparing 1kg nano Ag powder, it should be completed according to the following steps.

[0035] 1. Weigh 1.574kg AgNO 3 Powder, by AgNO 3 :H 2 O=85:1000 was added to 18.54Kg distilled water at a mass ratio of 0.5mol / L, heated to 80°C to fully dissolve, and prepared into 20.11 Kg AgNO 3 aqueous solution;

[0036] 2. Press PVA: H 2O =2:100 (mass ratio), add 0.197Kg PVA to 9.85Kg distilled water, heat and stir at 100°C until completely dissolved, that is, prepare 10.06Kg PVA release agent solution for use.

[0037] 3. Prepare (silver nitrate-PVA) binary mixture.

[0038] In the above 20.11KgAgNO 3 In aqueous solution, according to PVA solution: AgNO 3 Solution=1:2 (mass ratio) Add 10.05Kg of PVA aqueous solution to prepare 30.16Kg (silver nitrate-PVA) binary mixture.

[0039] 4. Preparation of silver nitrate-NaOH-PVA ternary mixed solution

[0040] By NaOH: AgNO 3 =1:2.5 mass ratio, 0.742Kg NaOH was made into 19.3kg solution at a concentration...

Embodiment 2

[0056] Embodiment 2: when preparing 500g nanometer Ag powder, should complete according to the following steps

[0057] 1. Weigh 0.787kg AgNO 3 powder, the AgNO 3 Press AgNO 3 :H 2 Add O=85:1000 mass ratio to 9.265Kg distilled water, heat to 60°C, and stir vigorously to prepare 10.05Kg AgNO 3 aqueous solution;

[0058] 2. Prepare PVA solution, press PVA: H 2 O =2:100 (mass ratio) Weigh 0.099Kg of PVA powder and 4.925Kg of distilled water, heat and stir at 100°C until completely dissolved, that is, prepare 5.024Kg of PVA release agent solution for later use.

[0059] 3. Preparation of (silver nitrate-PVA) binary mixture

[0060] A total of 15.074Kg of the above two solutions of 1 and 2 were mixed to make a binary mixed solution;

[0061] 4. Preparation of silver nitrate-NaOH-PVA ternary mixed solution

[0062] Slowly pour 0.371kg NaOH into 9.65kg solution at (1mol / L) concentration into the above-mentioned (silver nitrate-PVA) binary mixture.

[0063] 5. Microwave act...

Embodiment 3

[0076] Embodiment 3: when preparing 500g nanometer Ag powder, should complete according to the following steps

[0077] 1. Weigh 0.787kg AgNO 3 powder, the AgNO 3 Press AgNO 3 :H 2 O=85:1000 mass ratio was added to 9.265Kg distilled water, heated to 70°C, and vigorously stirred to prepare 10.05Kg AgNO 3 aqueous solution;

[0078] 2. Prepare PVA solution, press PVA: H 2 O =2:100 (mass ratio) Weigh 0.099Kg of PVA powder and 4.925Kg of distilled water, heat and stir at 95°C until completely dissolved, that is, prepare 5.024Kg of PVA release agent solution for later use.

[0079] 3. Preparation of (silver nitrate-PVA) binary mixture

[0080] A total of 15.074Kg of the above two solutions of 1 and 2 were mixed to make a binary mixed solution;

[0081] 4. Preparation of silver nitrate-NaOH-PVA ternary mixed solution

[0082] Slowly pour 0.371kg NaOH into 9.65kg solution at (1mol / L) concentration into the above-mentioned (silver nitrate-PVA) binary mixture.

[0083] 5. Mic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com