Low-cost titanium alloy anti-oxidation annealing method

A titanium alloy and anti-oxidation technology, which is applied in the direction of fireproof coatings, coatings, furnace types, etc., can solve the problems of easy oxidation of titanium alloys, and achieve the effects of stable surface protective coatings, less argon consumption, and low manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

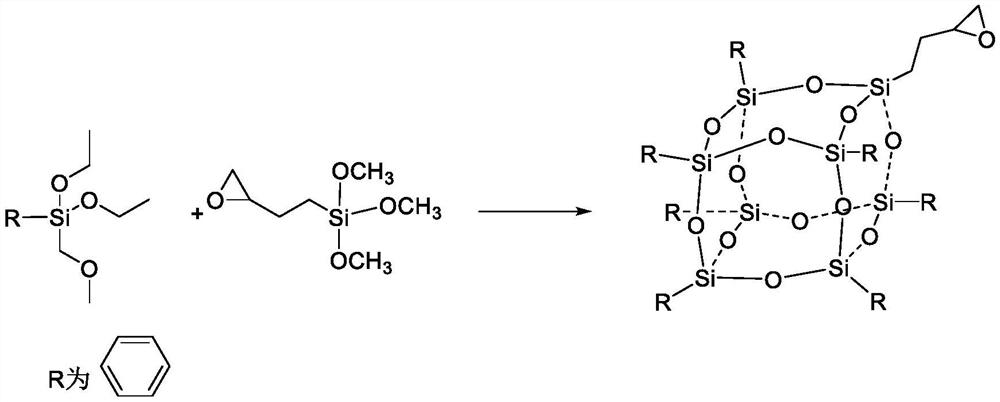

[0034] Modified silicone resins are made through the following steps:

[0035]Step S1, adding absolute ethanol into a three-necked flask equipped with a magnetic stirrer, a thermometer and a reflux condenser, heating the temperature of the reaction system to 35°C, then adding deionized water and hydrochloric acid, stirring for 25 minutes, and adding dropwise The mixture of triethoxysilane and epoxybutyltrimethoxysilane, the dropping speed is 1 drop / second, continue the hydrolysis reaction for 3 days after the drop is complete, and then adjust the pH of the reaction solution to neutral with NaOH aqueous solution, and depressurize The solvent was distilled off, washed 3 times with deionized water, dried over anhydrous magnesium sulfate, and filtered to obtain epoxy polyhedral silsesquioxane;

[0036] Step S2, add water and acetone into a three-neck flask equipped with a condenser, a constant pressure dropping funnel and a mechanical stirrer, after stirring evenly, adjust the pH ...

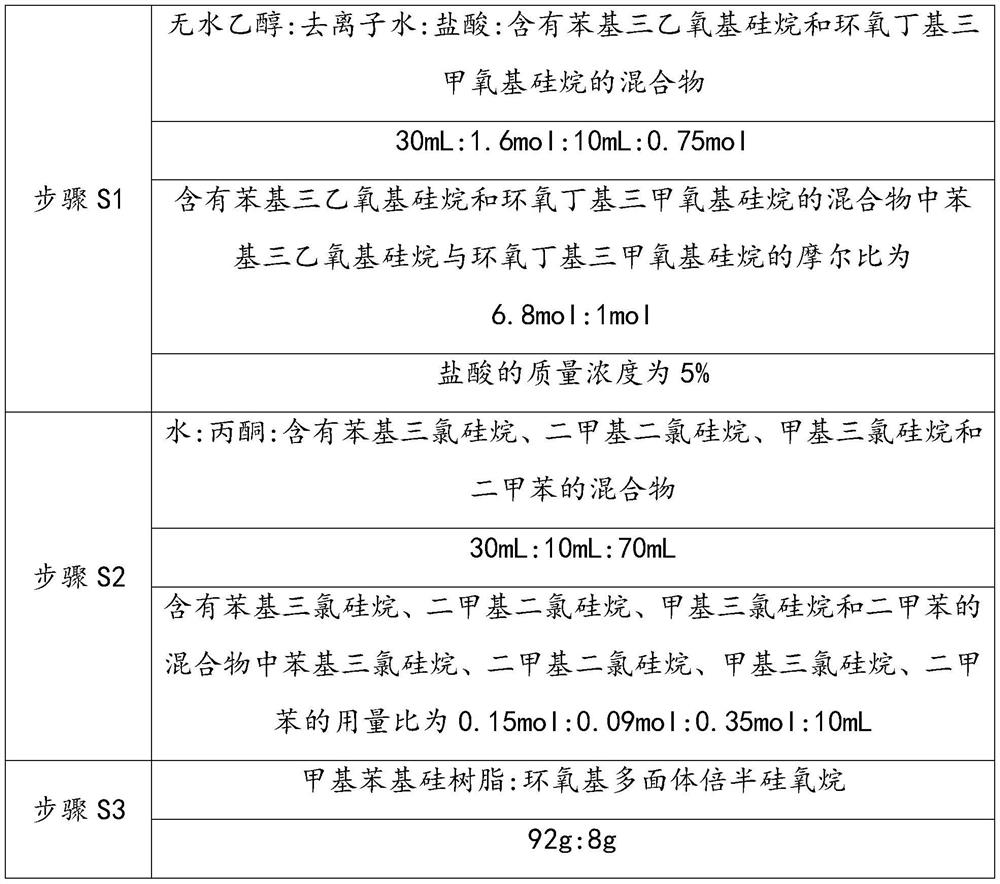

Embodiment 2

[0042] Modified silicone resin is made through the following steps: make with reference to each step in Example 1.

[0043] The consumption ratio of raw material in the step is as shown in table 2.

[0044] Table 2

[0045]

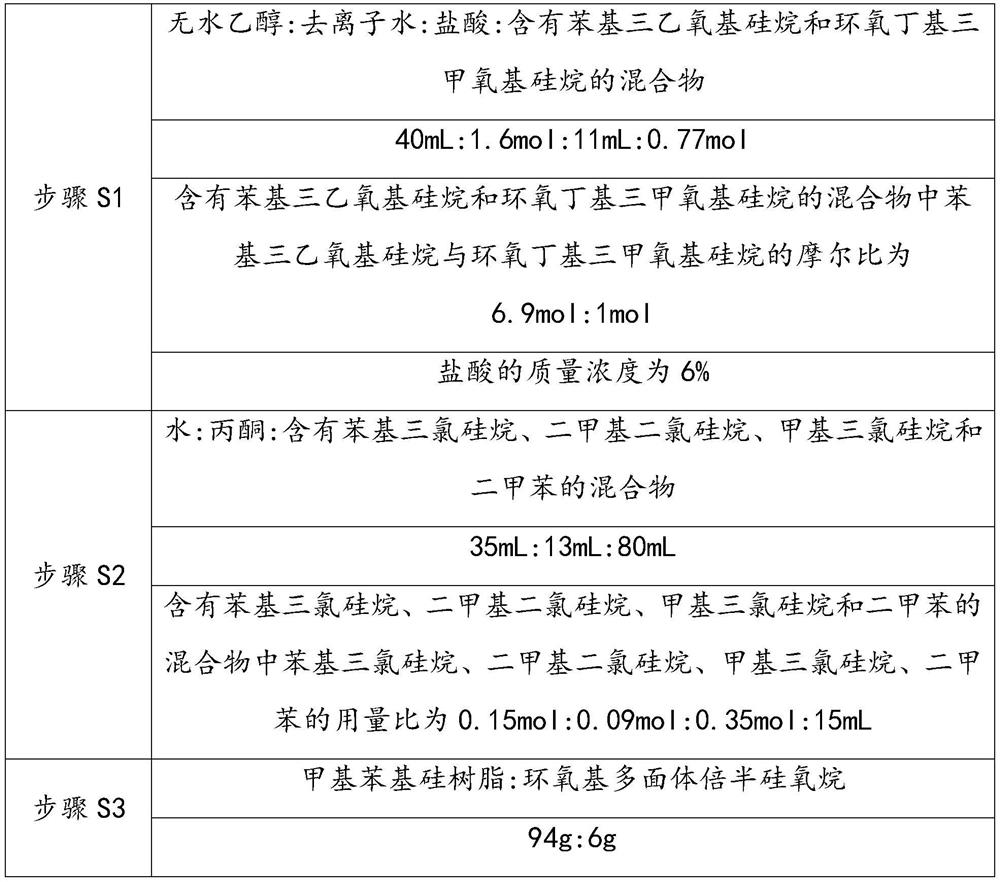

Embodiment 3

[0047] Modified silicone resin is made through the following steps: make with reference to each step in Example 1.

[0048] The consumption ratio of raw material in the step is as shown in table 3.

[0049] table 3

[0050]

[0051]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com