A kind of titanium-steel composite plate double-wire MIG gas shielded welding welding method

A technology of molten electrode gas and welding method, which is applied in welding equipment, welding accessories, welding/welding/cutting objects, etc., can solve the problems of large welding stress and deformation, poor welding joint performance, limited inhibition effect, etc., and achieve welding deformation. Small, small weld contamination, the effect of suppressing the generation of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

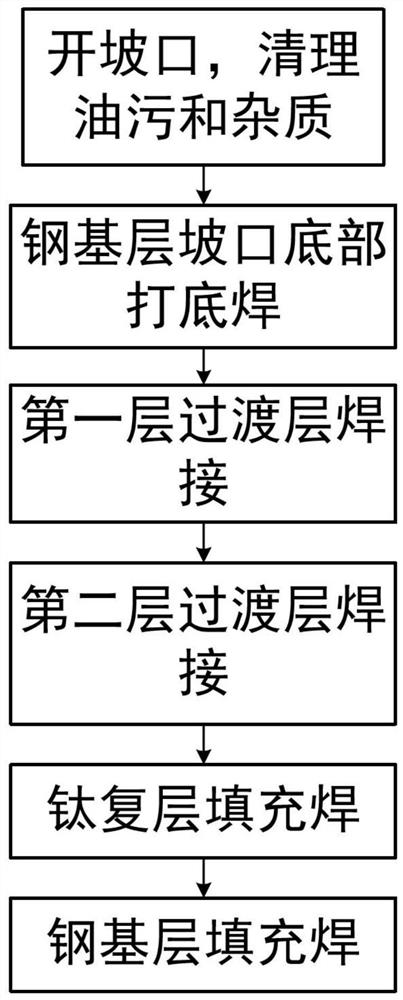

[0052] A TA1 / Q345 titanium-steel composite plate double-wire MIG welding method specifically includes the following steps:

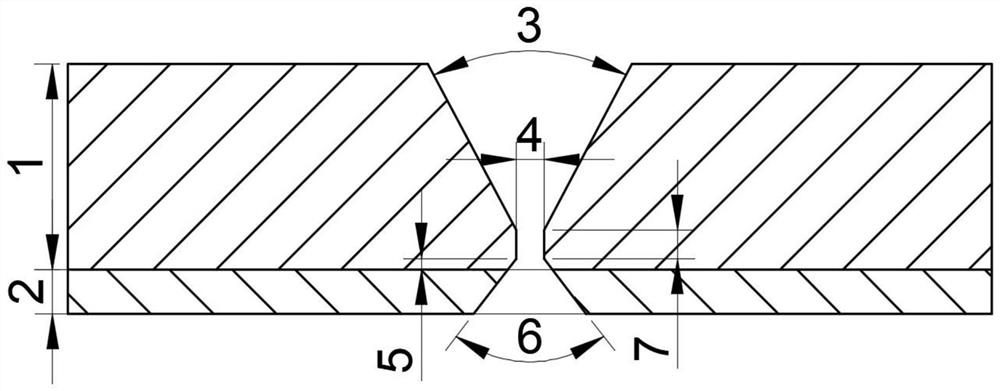

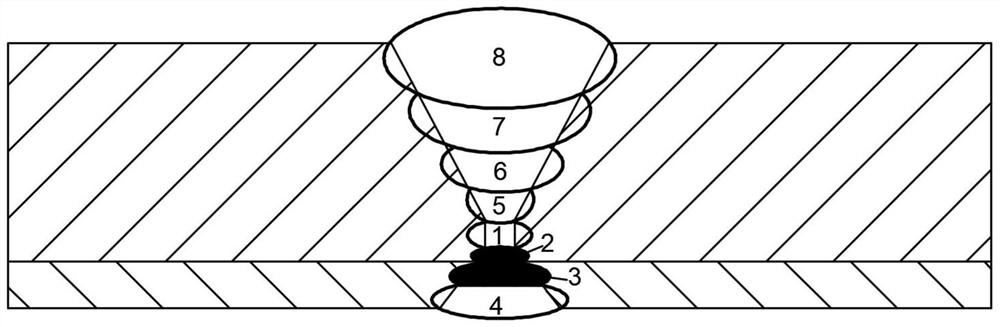

[0053] (1) The titanium steel clad plate to be welded is TA1 / Q345, and the groove design of the titanium steel clad plate is carried out. The size of the asymmetric X-shaped groove is shown in Table 1, and the groove is processed to remove the oil and impurities on the surface of the groove; Adjust the spatial position of the double wire. In the direction perpendicular to the welding direction, the distance between the projection points of the double wire end on the base metal plane is 0mm. In the direction parallel to the welding direction, the double wire is arranged in front and back as the leading welding wire and the following welding wire. The double wire end The distance between the projection points on the base metal plane is 5mm, the included angle between the axis extension line of the guiding welding wire and the base metal plane is 65°, and th...

Embodiment 2

[0068] A TA2 / Q345 titanium-steel composite plate double-wire MIG welding method specifically includes the following steps:

[0069] (1) The welded titanium-steel clad plate is TA2 / Q345, and the titanium-steel clad plate is grooved. The size of the asymmetric X-shaped groove is shown in Table 5. The groove is processed to remove the oil and impurities on the groove surface; Adjust the spatial position of the double wire. In the direction perpendicular to the welding direction, the distance between the projection points of the end of the double wire on the base metal plane is 0mm. In the direction parallel to the welding direction, the double wire is arranged in front and back as the leading welding wire and the following welding wire. The distance between the projection points on the base metal plane is 12mm, the included angle between the axis extension line of the guiding wire and the base metal plane is 75°, and the included angle between the axis extension line of the follow...

Embodiment 3

[0084] A TA2 / Q235 titanium-steel composite plate double-wire MIG welding method specifically includes the following steps:

[0085] (1) The titanium steel clad plate to be welded is TA2 / Q235, and the groove design of the titanium steel clad plate is carried out. The size of the asymmetric X-shaped groove is shown in Table 9, and the groove is processed to remove the oil and impurities on the surface of the groove; Adjust the spatial position of the double wire. In the direction perpendicular to the welding direction, the distance between the projection points of the end of the double wire on the base metal plane is 0mm. In the direction parallel to the welding direction, the double wire is arranged in front and back as the leading welding wire and the following welding wire. The distance between the projection points on the base metal plane is 18mm, the included angle between the axis extension line of the guiding wire and the base metal plane is 85°, and the included angle bet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com