High-toughness cast magnesium-rare earth alloy and preparation method thereof

A magnesium rare earth alloy, high-strength technology, applied in the field of high strength and toughness cast magnesium rare earth alloy and its preparation, can solve the problems of restricting the application of cast magnesium alloys, improve room temperature strength and room temperature plasticity, increase the density of precipitated phases, and suppress crystal grains The effect of coarsening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

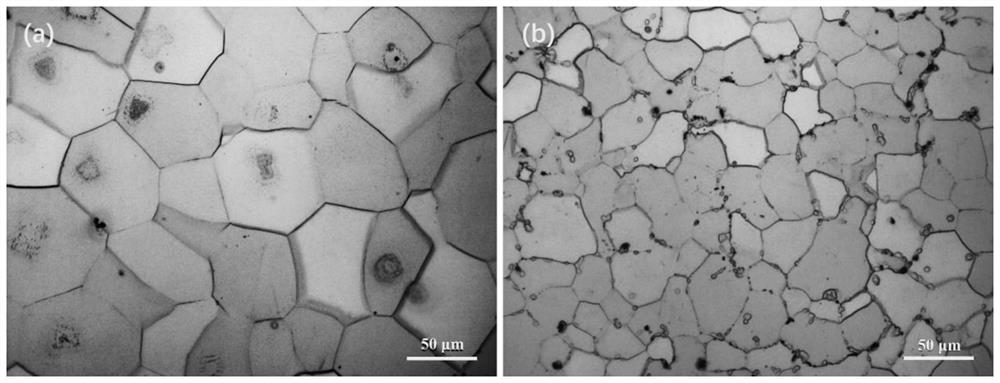

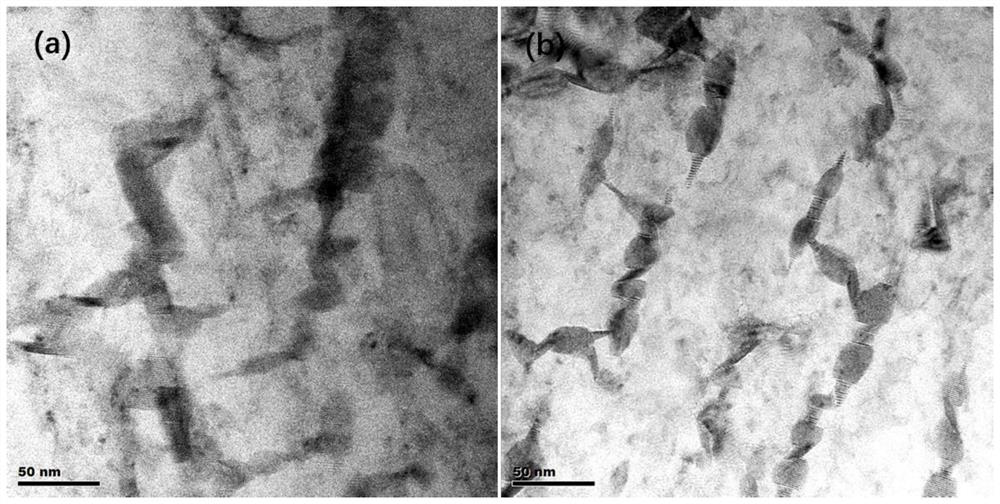

[0038]The present embodiment relates to a high-strength and toughness cast magnesium rare-earth alloy. The components and mass percentages of the magnesium alloy are: 10.2wt.%Gd, 0.2wt.%Zn, 0.1wt.%La, 0.4wt.%Zr, The total content of impurity elements Si, Fe, Cu and Ni is less than 0.2wt.%, and the balance is Mg (wt.% refers to the percentage of the components in the total mass of the prepared magnesium alloy, and the total mass is Mg, Zn and various the quality of the master alloy and).

[0039] This embodiment relates to the preparation method of the above-mentioned high-strength and toughness cast magnesium rare earth alloy, wherein the melting and casting process is performed in the SF 6 and CO 2 Under mixed gas protection conditions, the steps are as follows:

[0040] (1) Baking material: Preheat pure magnesium, pure zinc, Mg-Gd, Mg-La, Mg-Zr master alloy at 200°C for more than 3 hours.

[0041] (2) molten magnesium: put the pure magnesium after drying into SF 6 / CO 2...

Embodiment 2

[0048] This embodiment relates to a high-strength and toughness cast magnesium rare-earth alloy. The components and mass percentages of the magnesium alloy are: 10.2wt.%Gd, 0.2wt.%Zn, 0.2wt.%La, 0.4wt.%Zr, The total content of impurity elements Si, Fe, Cu and Ni is less than 0.2wt.%, and the balance is Mg (wt.% refers to the percentage of the components in the total mass of the prepared magnesium alloy, and the total mass is Mg, Zn and various the quality of the master alloy and).

[0049] This embodiment relates to the preparation method of the above-mentioned high-strength and toughness cast magnesium rare earth alloy, wherein the melting and casting process is performed in the SF 6 and CO 2 Under mixed gas protection conditions, the steps are as follows:

[0050] (1) Baking material: Preheat pure magnesium, pure zinc, Mg-Gd, Mg-La, Mg-Zr master alloy at 200°C for more than 3 hours.

[0051] (2) molten magnesium: put the pure magnesium after drying into SF 6 / CO 2 Melti...

Embodiment 3

[0058] The present embodiment relates to a high-strength and toughness cast magnesium rare-earth alloy. The components and mass percentages of the magnesium alloy are: 10.2wt.%Gd, 0.2wt.%Zn, 0.4wt.%La, 0.4wt.%Zr, The total content of impurity elements Si, Fe, Cu and Ni is less than 0.2wt.%, and the balance is Mg (wt.% refers to the percentage of the components in the total mass of the prepared magnesium alloy, and the total mass is Mg, Zn and various the quality of the master alloy and).

[0059] This embodiment relates to the preparation method of the above-mentioned high-strength and toughness cast magnesium rare earth alloy, wherein the melting and casting process is performed in the SF 6 and CO 2 Under mixed gas protection conditions, the steps are as follows:

[0060] (1) Baking material: Preheat pure magnesium, pure zinc, Mg-Gd, Mg-La, Mg-Zr master alloy at 200°C for more than 3 hours.

[0061] (2) molten magnesium: put the pure magnesium after drying into SF 6 / CO ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com