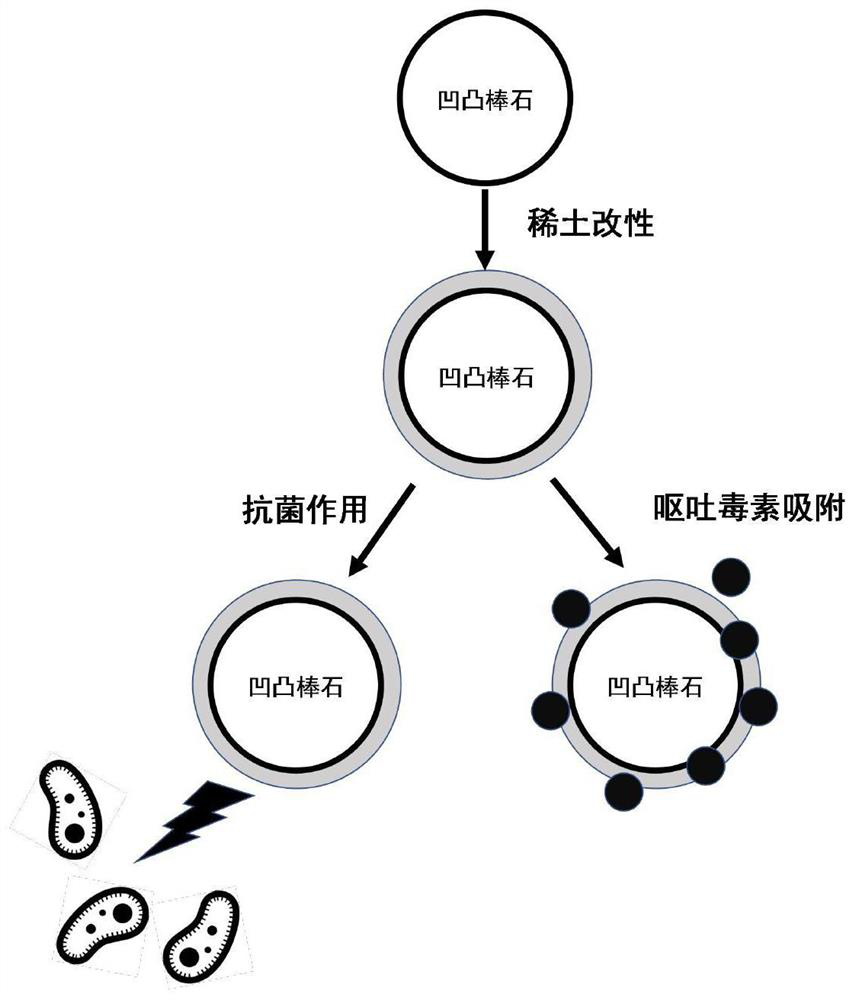

Preparation method of rare earth modified attapulgite feed additive

A feed additive, attapulgite technology, applied in animal feed, chemical instruments and methods, additional food elements, etc., to achieve the effects of improving the activity of animal digestive enzymes, inhibiting the growth of pathogenic bacteria, and making production conditions easier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

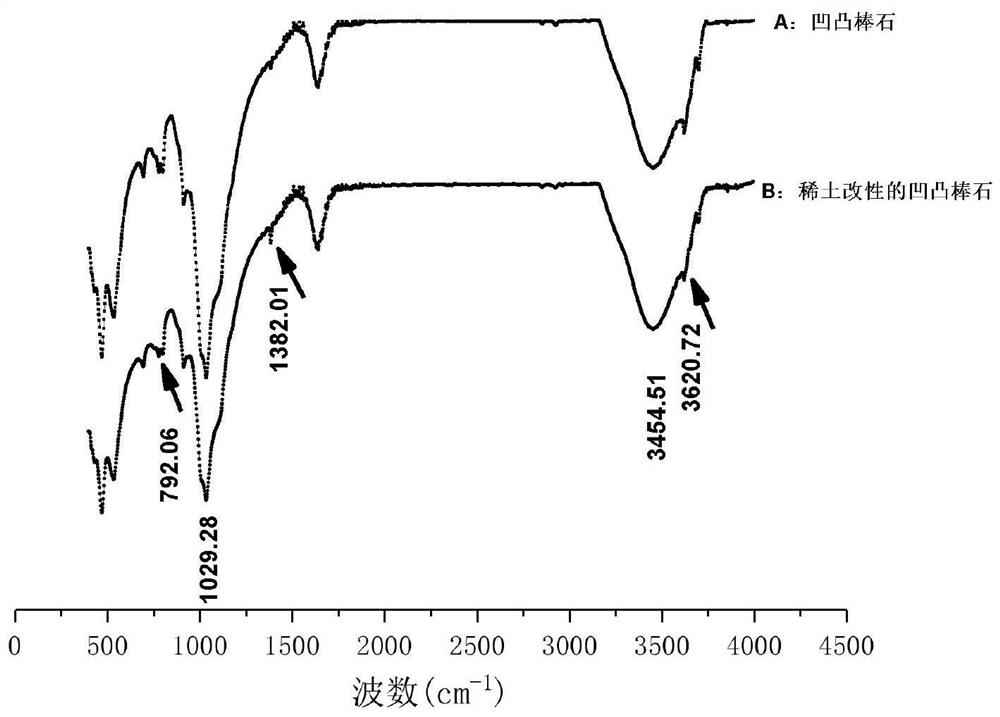

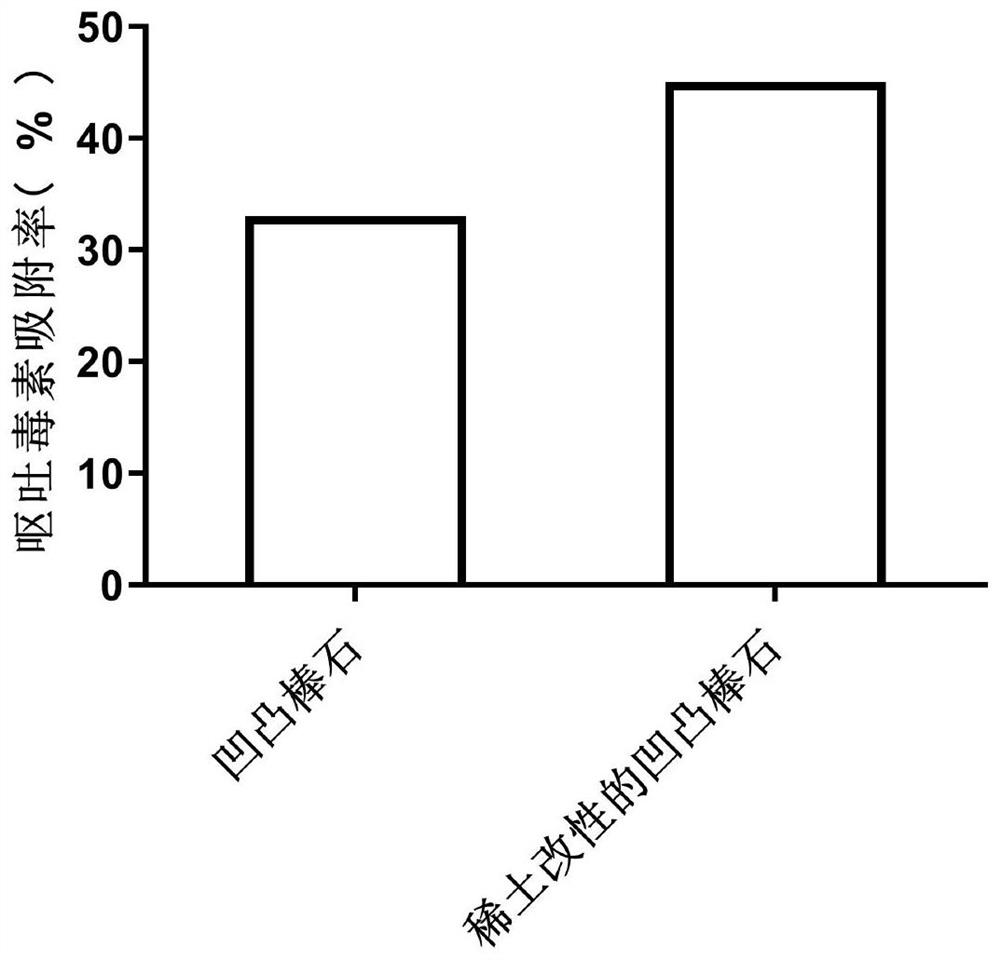

Embodiment example 1

[0028]Embodiment 1 Case: Weigh 100g attapulgite, pulverized to homogeneity using a grinding machine, through 300 mesh sieve, was added 500mL of water slurried, followed by addition of 10mmol / L citric acid in 240mL modified with a magnetic stirrer at after stirring for 8h at room temperature through a 200 mesh sieve to remove impurities, in hypoxic environment calcined at 300 ℃ acidified to give a modified attapulgite, through a 200 mesh sieve to obtain an acid-modified attapulgite powder. Weighed lanthanum oxide, cerium oxide, samarium oxide, the 30g, was added 500mL of 10mmol / L hydrochloric acid sufficient reaction 8h, filtered to remove impurities to prepare lanthanum, cerium, samarium rare earth ion modifier. Attapulgite powder and the above rare earth ions Modifier 1: 1 mixed, evaporated to dryness, in hypoxic environment 200-500 deg.] C to obtain calcined attapulgite modified rare earth element compound, followed by using a sufficient amount of deionized water, washed wit...

Embodiment example 2

[0029] Embodiment 2 Case: Weigh 100g attapulgite, pulverized to homogeneity using a grinding machine, through 300 mesh sieve, was added 500mL of water slurried, followed by addition of 180mL of 10mmol / L 4- phenyl-butyric acid modification, after stirring for 8h using a magnetic stirrer over a 200 mesh sieve to remove impurities at room temperature, in a hypoxic environment calcined at 300 ℃ to give 4-phenylbutyric acid modified attapulgite, through a 200 mesh sieve to obtain an acid-modified attapulgite powder. Lanthanum oxide sufficiently weighed 100g, was added 500mL of 10mmol / L hydrochloric acid to 4h, filtered to remove impurities, to obtain a lanthanum ion modifier. Attapulgite powder and the above rare earth ions Modifier 1: 1 mixed, evaporated to dryness, in hypoxic environment 200 ℃ obtained by firing the lanthanum ion modified attapulgite, and then using a sufficient amount of deionized water, ethanol washed three times each, and dried at 50-90 deg.] C 4h, ground to p...

Embodiment example 3

[0030] Embodiment 3 Case: Weigh 100g attapulgite, pulverized to homogeneity using a grinding machine, through 300 mesh sieve, was added 500mL of water slurried, followed by addition of 10mmol / L 480mL of acetic acid modification with a magnetic stirrer at room temperature after stirring for 8h under 200 mesh sieve to remove impurities, in a hypoxic environment to obtain calcined at 300 ℃ acid modified attapulgite, through a 200 mesh sieve to obtain an acid-modified attapulgite powder. Weigh sufficient terbium oxide, lutetium, scandium the 30g, was added 500mL of 10mmol / L, sulfuric acid reaction 4h, filtered to remove impurities to prepare terbium, lutetium, scandium ion modifier. Attapulgite powder and the above rare earth ions Modifier 1: 1 mixed, evaporated to dryness, in hypoxic environment 200 ℃ obtained by firing terbium, lutetium, scandium complex of the rare earth element-modified attapulgite, and then use the foot amount of deionized water, washed with ethanol three tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com