High strength and low tank pressure perfluorinated ion exchange membrane for chlor-alkali industry and preparation method thereof

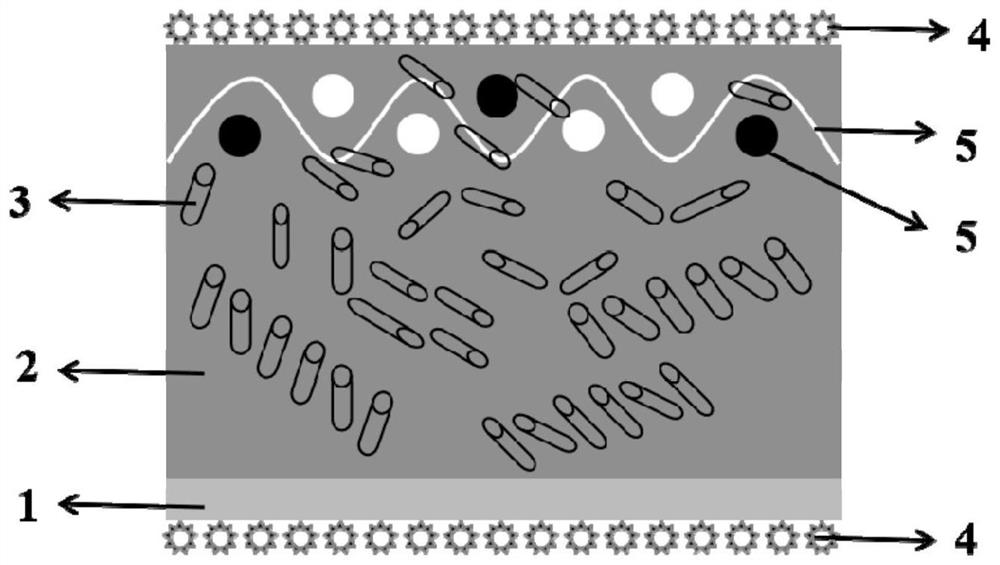

A technology of perfluorinated ion and chlor-alkali industry, applied in organic diaphragms, cells, electrolytic components, etc., can solve the problems of lack of fiber support and reinforcement, lack of ion exchange capacity, loss of mechanical strength of ion membrane, etc., to shorten the hydrolysis transformation time , avoid transmission resistance, improve the effect of mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The perfluorosulfonic acid resin in this example has an ion exchange capacity of 0.90 mmol / g, and is a powder obtained by copolymerization of tetrafluoroethylene and perfluoro 3,6-dioxa-4-methyl-7-octenesulfonyl fluoride body.

[0035] (1) Preparation of resin pellets

[0036] The micro-nano hollow fiber material with an outer diameter of 300nm, a length of 10μm, and an inner diameter of 20nm, and the above-mentioned perfluorosulfonic acid resin powder are fully mixed at a mass ratio of 1:100, and then melt-extruded and granulated to obtain a micro-nano hollow fiber. The material is pellets of perfluorosulfonic acid resin.

[0037] The powder obtained by copolymerization of tetrafluoroethylene and perfluoro 4,7-dioxa-5-methyl-8-nonenoate methyl ester is melt-extruded and granulated to obtain pellets of perfluorocarboxylic acid resin; ion exchange capacity It is 0.88mmol / g.

[0038] (2) Membrane preparation and reinforcement

[0039] The above-mentioned perfluorocarb...

Embodiment 2

[0044] The raw materials of perfluorosulfonic acid resin and perfluorocarboxylic acid resin powder are the same as in Example 1.

[0045] (1) Preparation of resin pellets

[0046] The micro-nano hollow fiber material with an outer diameter of 20 μm, a length of 50 μm, and an inner diameter of 50 nm, which has ion exchange capacity, is fully mixed with the above-mentioned perfluorosulfonic acid resin powder at a mass ratio of 10:100, and then melt-extruded and granulated to obtain a micro-nano hollow fiber. The material is pellets of perfluorosulfonic acid resin. The pellet preparation of perfluorocarboxylic acid resin is the same as in Example 1.

[0047] (2) Membrane preparation and reinforcement

[0048] Using the above-mentioned perfluorocarboxylic acid resin pellets and perfluorosulfonic acid resin pellets containing micro-nano hollow fiber materials, respectively obtain perfluorocarboxylic acid ion exchange resin membranes and perfluorosulfonic acid ion exchange resin m...

Embodiment 3

[0053] Step (1), step (2) and step (3) are identical with embodiment 1. The difference is that the micro-nano hollow fiber material with ion exchange capacity in step (1) has an outer diameter of 20 μm, a length of 10 μm, and an inner diameter of 10 nm.

[0054] The ion-exchange membrane prepared by the present embodiment has a tensile strength of 39MPa, and can be used for the ion-exchange membrane in the chlor-alkali ion-exchange membrane electrolyzer, at 6.0kA / m 2 Under the current density, the mass ratio concentration of the cathode NaOH solution is 32%, the concentration of the anode brine entering the tank is 305g / L, the concentration of the brine leaving the tank is 210g / L, the tank temperature is 86±1°C, the active cathode is under the conditions of zero pole distance Test, the cell voltage is 3.03V, after that, according to the standard SJ / T 10171.5 method, the surface resistance of the obtained film is 1.60Ω·cm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com