A kind of preparation method of semi-insulating indium phosphide

A semi-insulating indium phosphide technology, applied in the field of semi-insulating indium phosphide preparation, can solve the problems of less annealing of indium phosphide and inapplicability of indium phosphide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

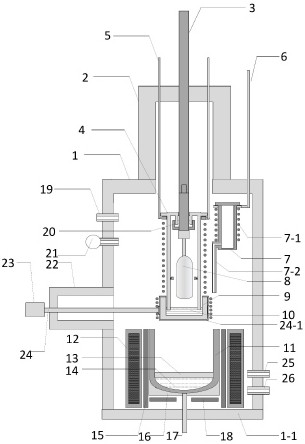

[0037] The present invention will be further described below with reference to the accompanying drawings.

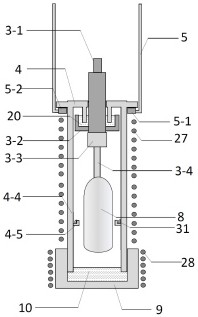

[0038] see figure 1 , a preparation device for semi-insulating indium phosphide, including a furnace body, a crucible 11 and a heating and support system, a seed rod 3 passing through the furnace body, and a hydrogen pipe 25 and an inert gas pipe 26 on the side of the furnace body. , Exhaust pipe 19; an injector 7 is provided in the furnace body, and the injection lifting rod 6 connecting the injector 7 protrudes out of the furnace body to connect to the drive device (marked in the figure); an in-situ annealing device is also set in the furnace body.

[0039] The heating and support system of the crucible 11 includes a heat preservation jacket 12 , a main heater 15 , a graphite support 16 , a crucible rod 17 , and a lower heater 18 .

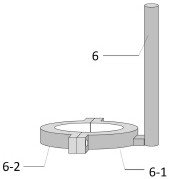

[0040] see figure 2 , the lift rod 6 is connected to the injector 7 through the injection lift rod right support 6-1 and the injection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com