Intrinsic safety treatment method for edge metal in decommissioned battery pole piece and application

A processing method and intrinsically safe technology, applied in the field of intrinsically safe processing of edge metals in retired battery pole pieces, can solve problems such as explosion and combustion, and achieve the effects of high activity, low processing cost and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

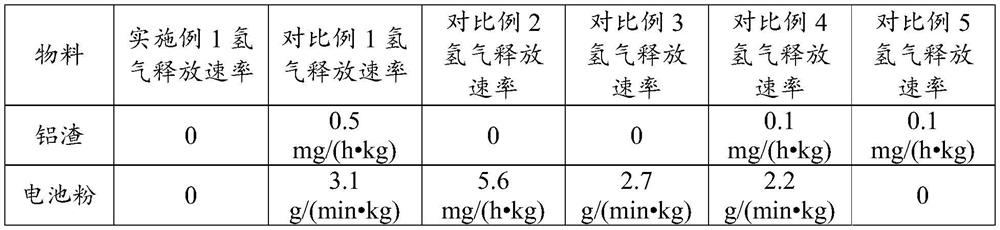

Embodiment 1

[0052] The intrinsically safe treatment method for the edge metal in the decommissioned battery pole piece of this embodiment includes the following specific steps:

[0053] (1) Cut the waste electrode sheet to a strip with a length of 50 mm and a width of 2 mm;

[0054] (2) Put the strip into the hydrothermal reaction kettle, the addition of the strip is 20% of the volume of the reaction kettle, add water according to the filling degree of 50%, and close the hydrothermal reaction kettle;

[0055] (3) Put the hydrothermal reaction kettle in the ultrasonic generator, heat the hydrothermal reaction kettle to 180°C in an oil bath in the ultrasonic generator, turn on the ultrasonic, control the ultrasonic power to 28kHz, and ultrasonically treat for 10 hours. Cool to room temperature to obtain pretreated aluminum slag;

[0056] (4) Take out the hydrothermal reaction kettle, filter the internal materials of the reaction kettle, rinse with water and then filter again, repeat severa...

Embodiment 2

[0063] The intrinsically safe treatment method for the edge metal in the decommissioned battery pole piece of this embodiment includes the following specific steps:

[0064] (1) Cut the waste electrode sheet to a strip with a length of 2mm and a width of 20mm;

[0065] (2) Put the strip into the hydrothermal reactor, the addition of the ribbon is 30% of the volume of the reactor, add water according to the filling degree of 60%, and close the hydrothermal reactor;

[0066] (3) Put the hydrothermal reaction kettle in the ultrasonic generator, heat the hydrothermal reaction kettle to 150°C in an oil bath in the ultrasonic generator, turn on the ultrasonic, control the ultrasonic power to 40kHz, and ultrasonically treat for 2 hours. Cool to room temperature to obtain pretreated aluminum slag;

[0067] (4) Take out the hydrothermal reaction kettle, filter the internal materials of the reaction kettle, rinse with water and then filter again, repeat several times, take the strip on...

Embodiment 3

[0074] The intrinsically safe treatment method for the edge metal in the decommissioned battery pole piece of this embodiment includes the following specific steps:

[0075] (1) Cut the waste electrode sheet to a strip with a length of 2mm and a width of 40mm;

[0076] (2) Put the strip into the hydrothermal reaction kettle, the addition of the strip is 50% of the volume of the reaction kettle, add water according to the filling degree of 80%, and close the hydrothermal reaction kettle;

[0077](3) Put the hydrothermal reaction kettle in the ultrasonic generator, heat the hydrothermal reaction kettle to 120°C in an oil bath in the ultrasonic generator, turn on the ultrasonic, control the ultrasonic power to 80kHz, and ultrasonically treat for 0.5h. Cool naturally to room temperature to obtain pretreated aluminum slag;

[0078] (4) Take out the hydrothermal reaction kettle, filter the internal materials of the reaction kettle, rinse with water and then filter again, repeat sev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com