A kind of vegetable oil-based polyacrylate nonionic emulsion and its preparation method and application

An oil-based polyacrylate and oil-based acrylate technology, which is applied in the field of vegetable oil-based polyacrylate nonionic emulsion and its preparation, can solve the problems of environmental and operator hazards, irritating odor, easy volatility, etc. Added value, improved storage stability, reduced usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

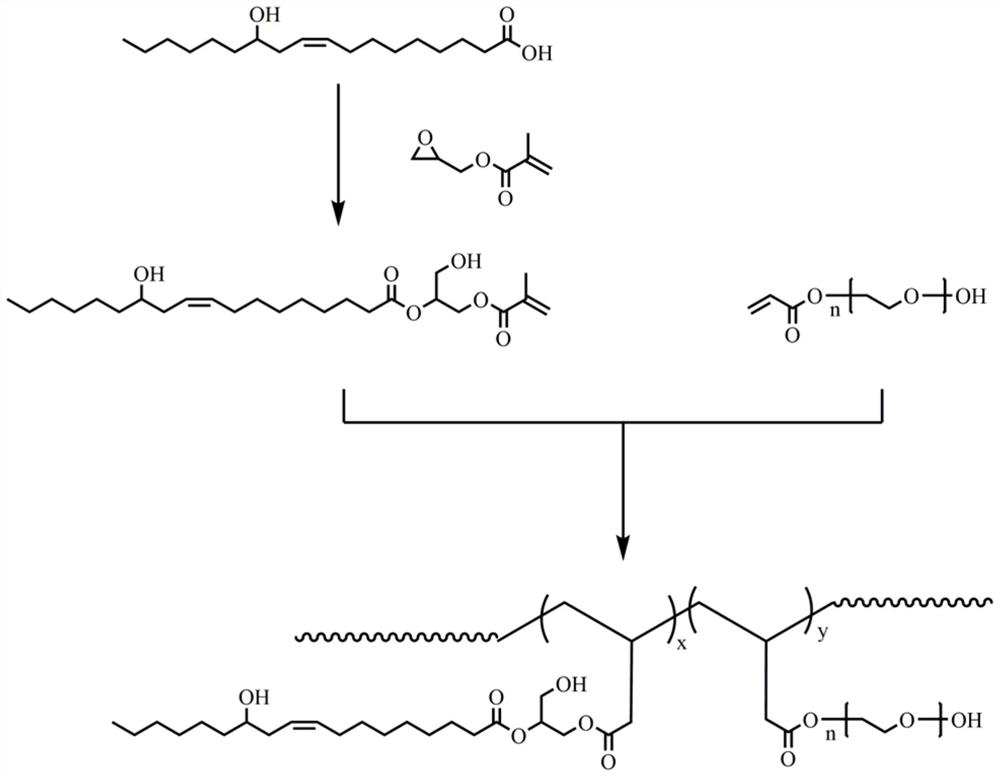

[0036] Add ricinoleic acid into the reaction kettle, stir and heat up to 60°C, add 1% ricinoleic acid weight tertiary ammonium salt catalyst N,N-dimethylethanolamine, then heat up to 80°C and add dropwise Glycidyl methacrylate of the polymerizing agent hydroquinone was reacted for 1 hour, and then heated to 90° C. for 4 hours to obtain ricinoleic acid acrylate.

[0037]Add 50g of propylene glycol butyl ether and 1g of initiator di-tert-butyl peroxide into a 500mL four-necked flask equipped with a stirrer, condenser, thermometer, and oil bath as a base material, stir, and heat up to a reflux temperature of 120°C under nitrogen protection. ℃. Mix 30g of ricinoleic acid acrylate, 10g of polyethylene glycol acrylate, 3.5g of di-tert-butyl peroxide, and 5g of dodecyl mercaptan, and stir magnetically for 15 minutes to evenly prepare mixed raw materials. After ℃, pre-throw 10wt% of the above-mentioned mixed raw materials into the flask with the preheated bottom material at one time ...

Embodiment 2

[0040] Add oleic acid in the reaction kettle, stir and heat up to 50°C, add 1% tertiary ammonium salt catalyst N,N-dimethylethanolamine by weight of oleic acid, then heat up to 70°C and dropwise add 0.05% polymerization inhibitor Glycidyl acrylate of benzoquinone was reacted for 2 hours, and then heated to 100°C for 3 hours to obtain oleic acid acrylate.

[0041] Add 25g of n-butanol and 1g of initiator di-tert-butyl peroxide into a 500mL four-necked flask equipped with a stirrer, condenser, thermometer, and oil bath as the base material, stir, and heat up to reflux temperature of 120°C under nitrogen protection. . Add 25g of oleic acid acrylate, 25g of polyethylene glycol acrylate, 3.5g of di-tert-butyl peroxide, and 5g of dodecyl mercaptan into a beaker and stir magnetically for 15 minutes to evenly prepare mixed raw materials. After ℃, pre-throw 10% of the above-mentioned mixed raw materials into the flask at one time to make the reaction "seed". After half an hour, use a...

Embodiment 3

[0044] Add linoleic acid into the reaction kettle, stir and heat up to 70°C, add tertiary ammonium salt catalyst N,N-dimethylethanolamine with 1% weight of linoleic acid, then heat up to 90°C and add dropwise Hydroxyethyl methacrylate of methylhydroquinone was reacted for 1 hour, and then heated to 100°C for 3 hours to obtain linoleic acid acrylate.

[0045] In a 500mL four-neck flask equipped with a stirrer, condenser, thermometer, and oil bath, add 50g of propylene glycol methyl ether acetate and 1g of initiator azobisisobutylcyanide as a base material, stir, and heat up to reflux temperature under nitrogen protection. 120°C. Add 20g of linoleic acid acrylate, 20g of polyethylene glycol acrylate, 3.5g of azobisisobutylcyanide, and 5g of mercaptoethanol into a beaker and stir magnetically for 15 minutes to prepare the mixed raw materials. Pre-throw 10% of the above-mentioned mixed raw materials in the flask as reaction "seeds". After half an hour, use a constant flow pump t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| water resistance | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com