Preparation method of amomum villosum essential oil microcapsule

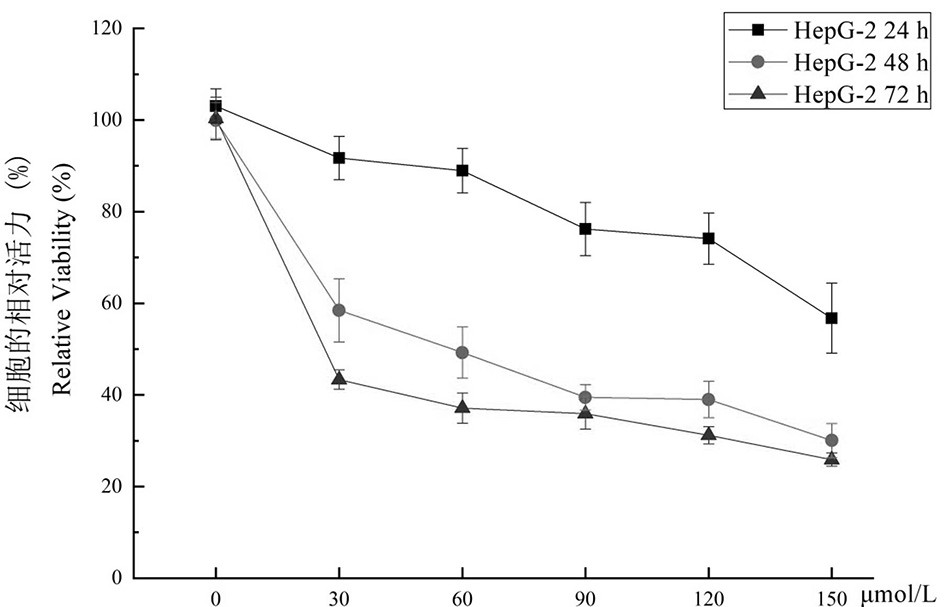

A technology for microcapsules and essential oils, applied in the field of preparation of Amomum chinensis essential oil microcapsules, can solve problems such as unreported efficacy and effects, and achieve the effects of significant antioxidant activity, convenient use, and improved utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The preparation method of Amomum essential oil microcapsules provided by the embodiment of the present invention specifically includes the following steps.

[0026] (1) Dissolve inulin, pectin, chitosan, and lysozyme in deionized water respectively, and prepare a 1mg / ml aqueous solution.

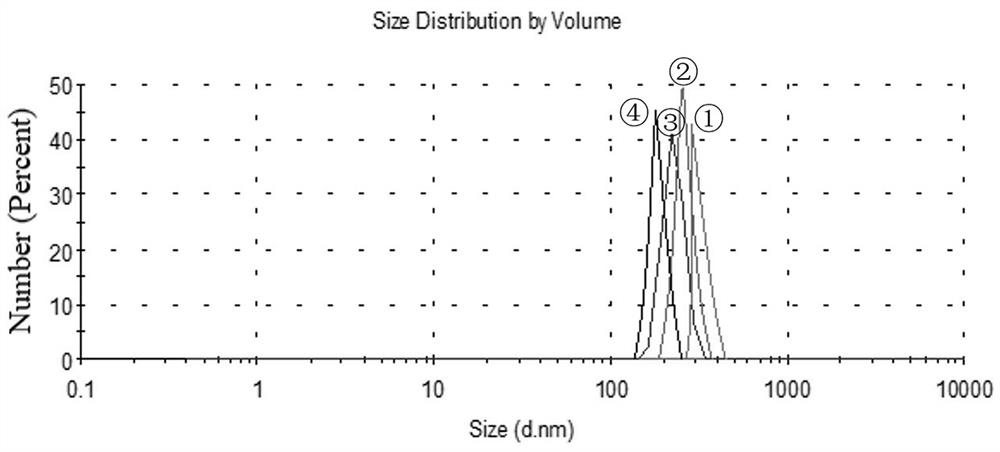

[0027] (2) Prepare the aqueous solution in step (1) according to the mass ratio of the two components of 1:4~4:1 to prepare inulin-lysozyme nanoparticle aqueous solution, inulin-chitosan nanoparticle aqueous solution, pectin-lysozyme Nanoparticle aqueous solution and pectin-chitosan nanoparticle aqueous solution were ultrasonically dispersed for 30-60 min at a power of 200W.

[0028] (3) Use 0.5mol / L hydrochloric acid and sodium hydroxide aqueous solution to adjust the pH of the system to 3~10 in the mixed solution in step (2).

[0029] (4) Add Amomum essential oil to the aqueous solution of nanoparticles obtained in step (3), the mass ratio of Amomum essential oil to the aqueous sol...

Embodiment 1

[0044] (1) Dissolve pectin and lysozyme in deionized water respectively, and prepare a 1mg / ml aqueous solution.

[0045] (2) The aqueous solution in step (1) was prepared in an aqueous solution of pectin-lysozyme nanoparticles according to the mass ratio of the two components of 4:1, and ultrasonically dispersed at a power of 200W for 60 min.

[0046] (3) Adjust the pH of the system to 10 with 0.5 mol / L aqueous sodium hydroxide solution in the mixed solution in step (2).

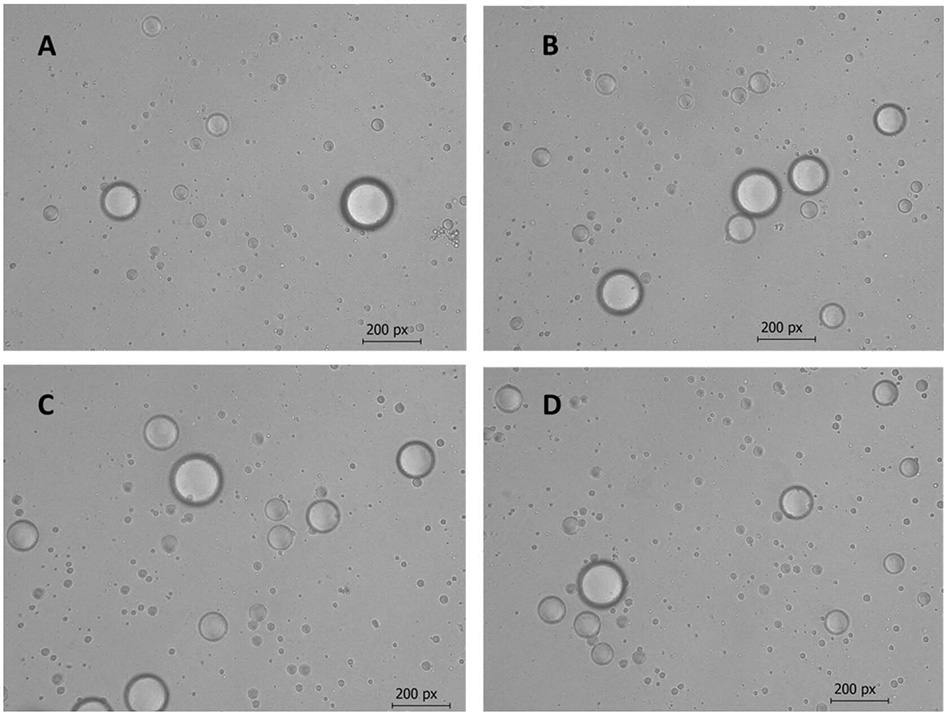

[0047] (4) Amomum essential oil was added to the aqueous solution of nanoparticles obtained in step (3). The mass ratio of Amomum essential oil to the aqueous solution of nanoparticles was 1:2, and the resulting mixed solution was dispersed at a high speed of 1600 r / min for 5 minutes.

[0048] (5) Spray-dry the mixed solution obtained in step (4), set the inlet air temperature at 180°C, the outlet temperature at 85°C, and the feed rate at 5mL / min for spray-drying to obtain amomum essential oil microcapsules....

Embodiment 2

[0053] (1) Dissolve pectin and chitosan in deionized water respectively, and prepare a 1mg / ml aqueous solution.

[0054] (2) The aqueous solution in step (1) was prepared in an aqueous solution of pectin-chitosan nanoparticles at a mass ratio of two components of 2:1, and ultrasonically dispersed at a power of 200W for 45 min.

[0055] (3) Adjust the pH of the system to 3 with the mixed solution in step (2) with 0.5 mol / L hydrochloric acid aqueous solution respectively.

[0056] (4) Amomum essential oil was added to the aqueous solution of nanoparticles obtained in step (3). The mass ratio of Amomum essential oil to aqueous solution of nanoparticles was 2:1, and the resulting mixed solution was dispersed at a high speed of 800 r / min for 30 minutes.

[0057] (5) Spray-dry the mixed solution obtained in step (4), set the inlet air temperature at 180°C, the outlet temperature at 85°C, and the feed rate at 5mL / min for spray-drying to obtain amomum essential oil microcapsules.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com