Supported catalyst based on fiber carrier, preparation method thereof and indoor air purification device

A technology for supporting catalysts and carriers, which is applied in the field of catalyst preparation, can solve the problems of difficulty in meeting actual production needs, reduced mechanical properties, and high technical costs, and achieve the effects of promoting bonding, high loading capacity, and firm bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] In order to solve the problems existing in the above-mentioned prior art, an embodiment of the present invention provides a method for preparing a supported catalyst based on a fiber carrier, comprising the following steps:

[0029] placing the fiber carrier in a stirring device, adding the active ingredient in stages, and mechanically stirring once after each addition, so as to load the active ingredient on the fiber carrier;

[0030] The single mechanical stirring process is as follows: the stirring speed is 500rad / min~1500rad / min, the stirring power is 0.5kW~2.5kW, during the stirring process, there is a pause every 5s~12s, the pause time is 3s~10s, and the total stirring time is 20s ~50s, the temperature in the stirring device is kept at 25°C~80°C;

[0031] Wherein, the active ingredient is metal nanoparticles or metal oxide nanoparticles.

[0032]The preparation method of the supported catalyst based on the fiber carrier provided in the embodiment of the present i...

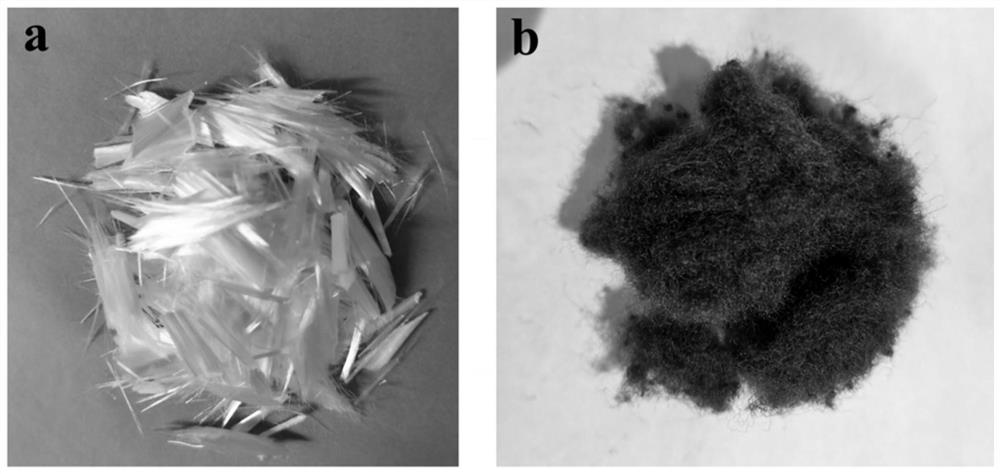

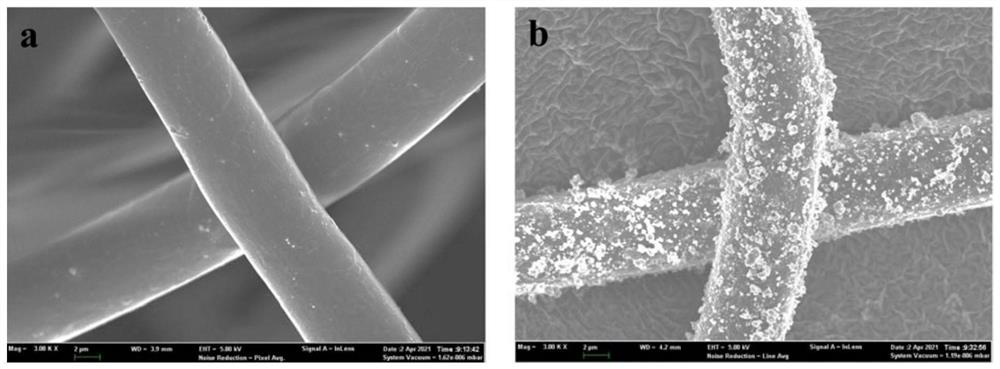

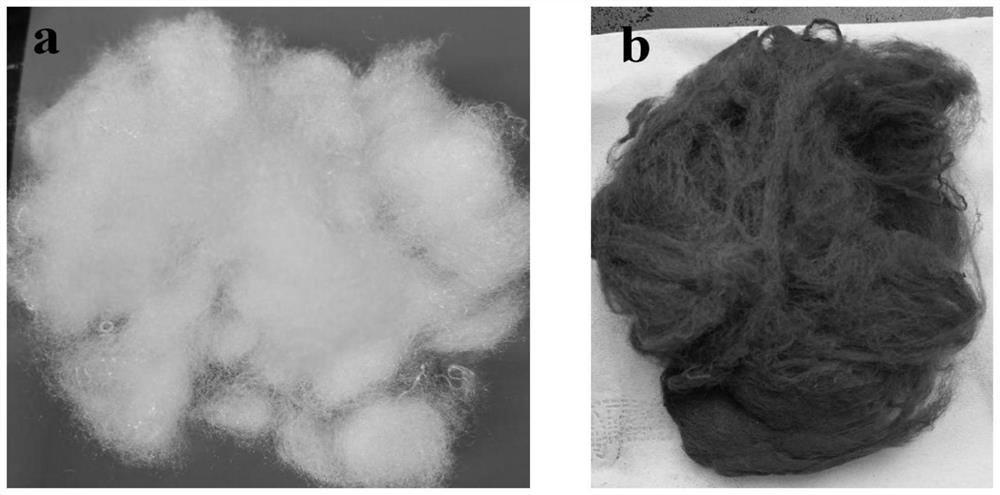

Embodiment 1

[0051] (1) Weigh 2g of polyester fiber with a diameter of 7μm, 0.3g of manganese dioxide (MnO 2 ) nanoparticles, put into a mixer, the power of the mixer is 1.5kW, and the set speed is 1500rad / min. Start the stirring device for 5s, after an interval of 3s, start again. This operation was repeated 4 times to complete the first mechanical stirring. After the stirring was finished, the temperature in the stirring device was measured to be 55°C.

[0052] (2) Unscrew the lid of the mixer and add 0.3g MnO 2 Nanoparticles, start the mixer again, and carry out the second mechanical stirring, which is the same as the first mechanical stirring operation. The power and speed of the mixer are unchanged, and the stirring device is started for 5 seconds. After an interval of 3 seconds, start again and repeat 4 times. After the stirring was finished, the temperature in the stirring device was measured to be 55°C.

[0053] (3) Repeat step (2), carry out mechanical stirring for the third t...

Embodiment 2

[0057] (1) Weigh 3g of viscose fiber with a diameter of 30 μm, 0.8g of tricobalt tetroxide (Co 3 o 4 ) nanoparticles, put into a mixer, the power of the mixer is 1kW, and the set speed is 1200rad / min. Start the stirring device for 10s, after a 5s interval, start again. This operation was repeated 5 times to complete the first mechanical stirring. After the stirring was finished, the temperature in the stirring device was measured to be 60°C.

[0058] (2) Unscrew the lid of the blender, add 0.8g Co 3 o 4 Nanoparticles, start the mixer again, and carry out the second mechanical stirring, which is the same as the first mechanical stirring operation. The power and speed of the mixer are unchanged, and the stirring device is started for 10 seconds. After an interval of 5 seconds, start again and repeat 5 times. After the stirring was finished, the temperature in the stirring device was measured to be 60°C.

[0059] (3) repeat step (2) 3 times, carry out mechanical stirring fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com