Winding insulation electric-thermal-mechanical combined accelerated aging device and method

A winding insulation and accelerated aging technology, applied in the direction of using mechanical devices, measuring devices, measuring electricity, etc., can solve the problem of incomplete simulation of insulation electric field, thermal field, mechanical force and harsh environment, high manufacturing cost and low aging efficiency and other issues to achieve the effect of improving aging efficiency, reducing aging cost and increasing corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

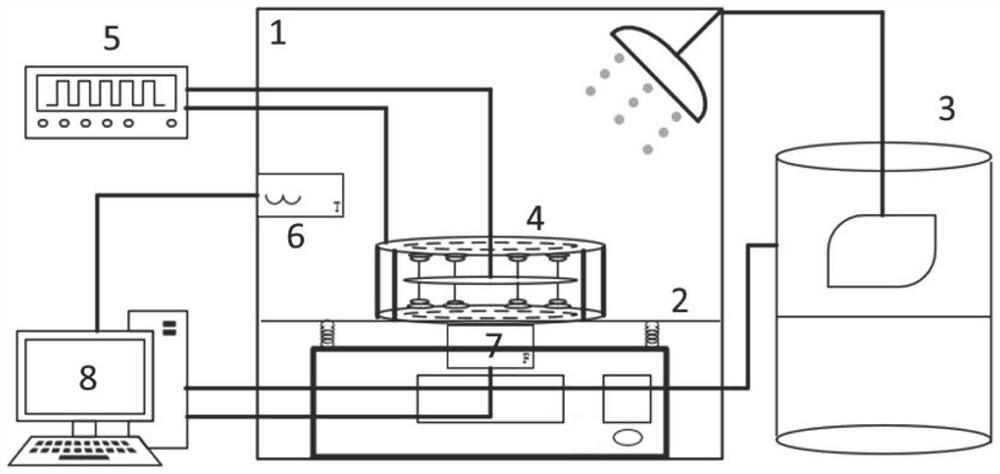

[0027] Such as figure 1 As shown, this embodiment relates to a winding insulation electric-thermal-mechanical accelerated aging device, including: an oven 1, a vibration generating device 2 and an electrode aging unit 4 arranged in the oven 1, and an output terminal facing the electrode aging unit 4 The salt mist generating device 3 provided, wherein: the control terminals of the oven 1, the vibration generating device 2, and the salt mist generating device 3 are respectively connected to the control module 8, and the input end of the electrode aging unit 4 is connected to the high-frequency square wave power supply 5, The oven 1 and the vibration generating device 2 are respectively provided with a salt spray sensor 6 and a vibration sensor 7 connected to the control module 8 , and the electrodes to be treated are arranged in the electrode aging unit 4 .

[0028] The electrode aging unit 4 is a three-layer plate column structure, wherein the first layer copper plate and the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com