Saccharides-assisted boron nitride stripping method and application

A boron nitride and sugar technology, applied in chemical instruments and methods, nitrogen compounds, inorganic chemistry, etc., can solve the problems of cumbersome and complicated steps, unfavorable for large-scale production, and limit the wide application of BNNSs, so as to solve the wave absorbing performance. and heat storage and transfer, improve poor thermal conductivity, and improve corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

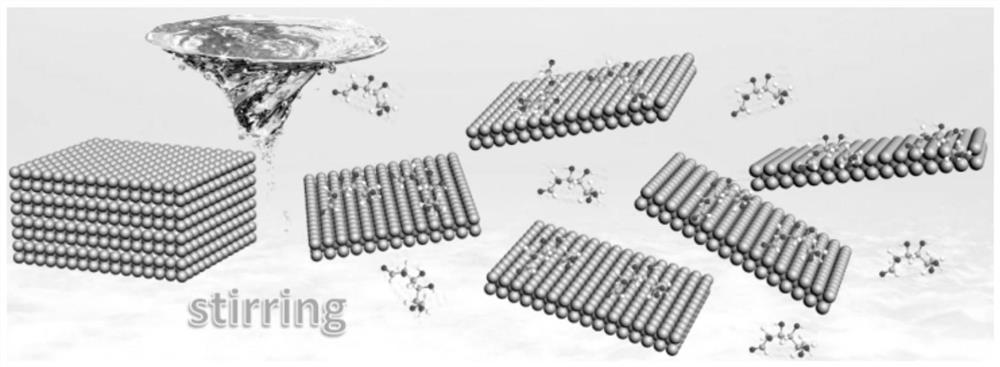

Method used

Image

Examples

Embodiment 1

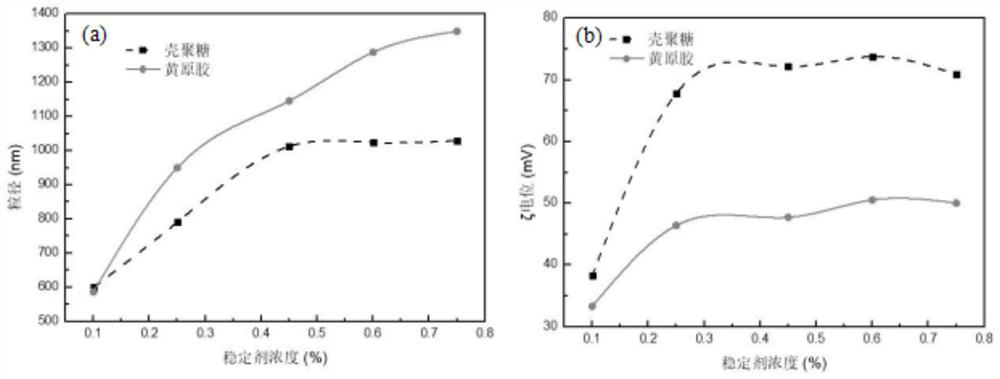

[0036] (1) 0.8g chitosan is dissolved in 200mL acetic acid (2wt.%) aqueous solution, obtains the carbohydrate solution of 0.4%;

[0037] (2) Then disperse 1.0g h-BN into the solution of (1), and stir rapidly for 30 minutes to ensure that the h-BN is uniformly dispersed, and the concentration of the h-BN suspension is 5mg / mL;

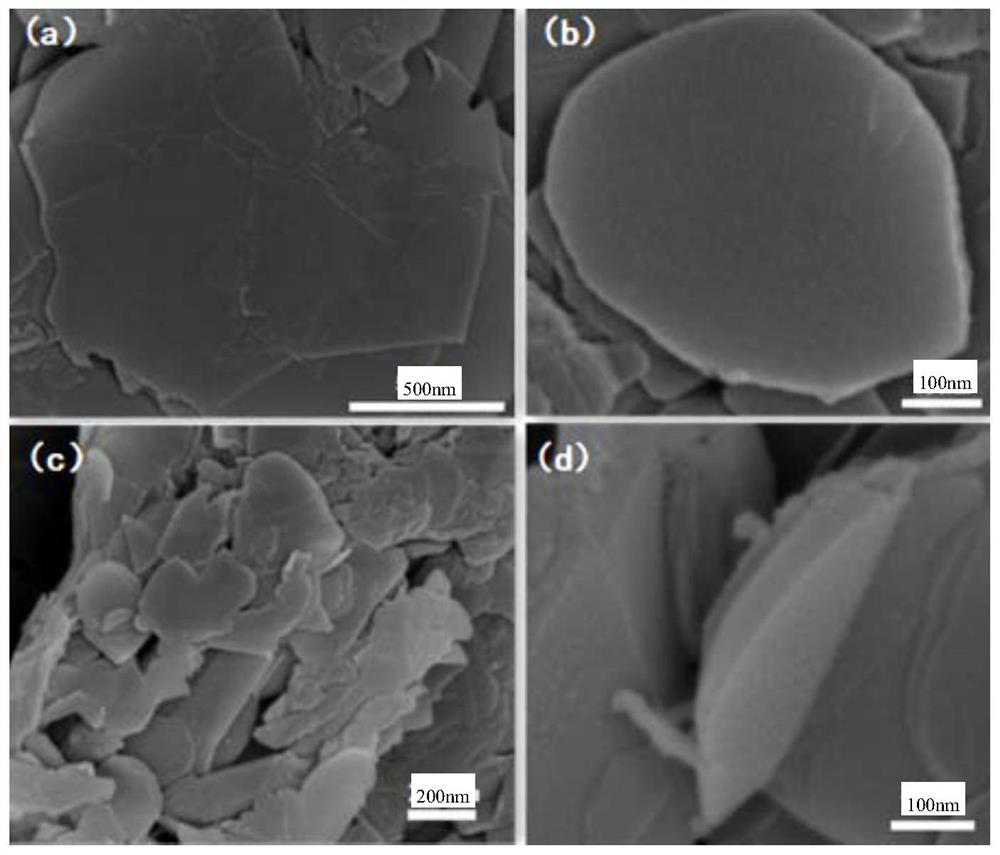

[0038] (3) Shearing is performed with a high-shear dispersing emulsifier, the shearing speed is set at 8000 rpm, and the shearing time is 90 minutes. In order to avoid the temperature rise of the system due to shearing and affect the peeling effect, the suspension was placed in a cold water bath, and the temperature was kept at 25-35°C to obtain the BNNSs suspension;

[0039] (4) The BNNSs suspension was centrifuged at a centrifugal speed of 4000rpm for 30min. The supernatant obtained was stripped BN, and the lower layer was bulk BN. The supernatant was dried, and the lower layer could be left for further stripping.

Embodiment 2

[0041] (1) Fully dissolve 1.0 g of glucose into 200 mL of deionized water to obtain a 0.5% sugar solution;

[0042] (2) Then disperse 2.0g h-BN into the solution of (1), ultrasonicate at room temperature for 30min, and stir for 6h to ensure that h-BN is uniformly dispersed, and the concentration of h-BN suspension is 10mg / mL;

[0043] (3) Shearing is performed with a high-shear dispersing emulsifier, the shearing speed is set at 6500 rpm, and the shearing time is 60 minutes. In order to avoid the temperature rise of the system due to shearing and affect the peeling effect, the suspension was placed in a cold water bath, and the temperature was kept at 25-35°C to obtain the BNNSs suspension;

[0044] (4) The BNNSs suspension obtained after shear dispersion was added to the water-based polyurethane, and the BNNSs was mixed with the water-based polyurethane with a solid content of 30%, ultrasonicated for 10 min by an ultrasonic instrument, and then stirred by magnetic force for 1...

Embodiment 3

[0048] (1) Fully dissolve 2.0 g of sucrose with molecular weight in 200 mL of water to obtain a 1.0% sugar solution;

[0049] (2) Then disperse 4.0g c-BN into the solution of (1), ultrasonicate at room temperature for 30min, and stir for 12h to ensure that c-BN is evenly dispersed, and the concentration of BN suspension is 20mg / mL;

[0050] (3) Shearing is performed with a high-shear dispersing emulsifier, the shearing speed is set at 8000 rpm, and the shearing time is 90 minutes. In order to avoid the peeling effect being affected by the temperature rise of the system due to shearing, the suspension was placed in a cold water bath, and the temperature was kept at 25-35°C to obtain the suspension;

[0051] (4) The suspension was filtered with slow qualitative filter paper, and washed with deionized water, and the washing process was repeated 3 times. The collected solids were redispersed in deionized water and sonicated for several minutes. Then centrifuged at 3000g for 40mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com