Shape memory polyurethane bone scaffold prepared by gas foaming method and application thereof

A gas foaming, bone scaffolding technology, applied in prosthesis, medical science, tissue regeneration, etc., can solve problems such as infection and adverse patient recovery, and achieve the effects of promoting growth, excellent bone conductivity, and proper porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

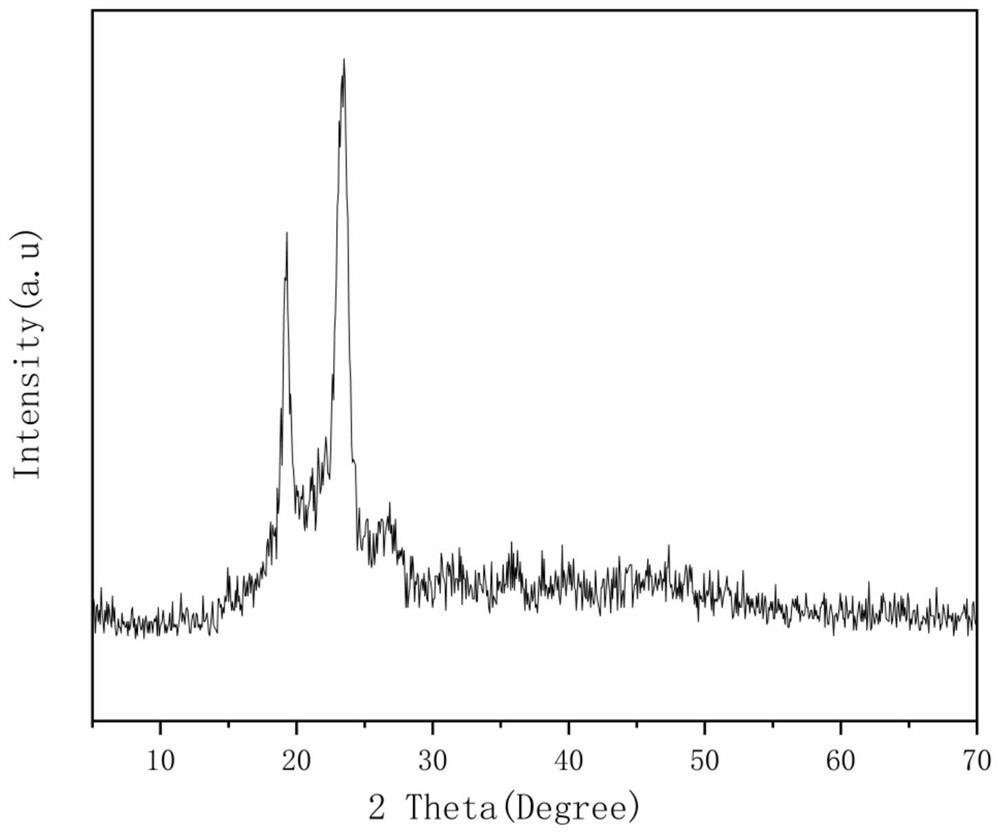

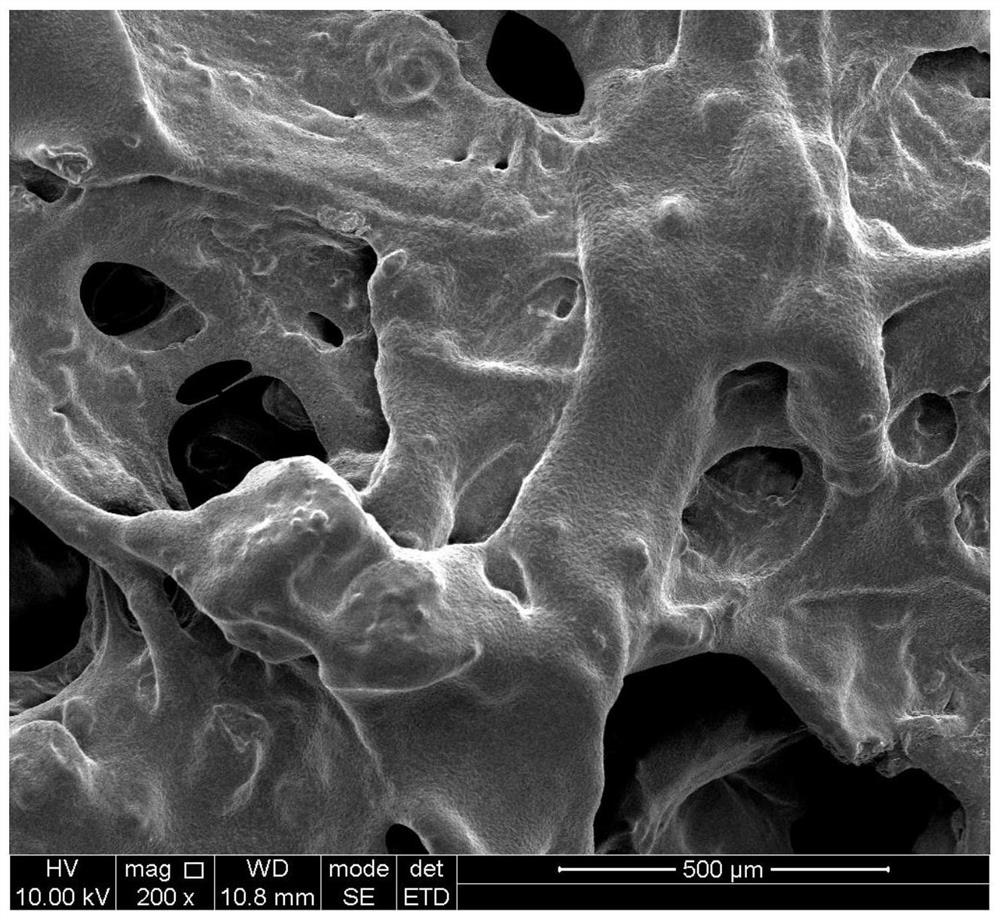

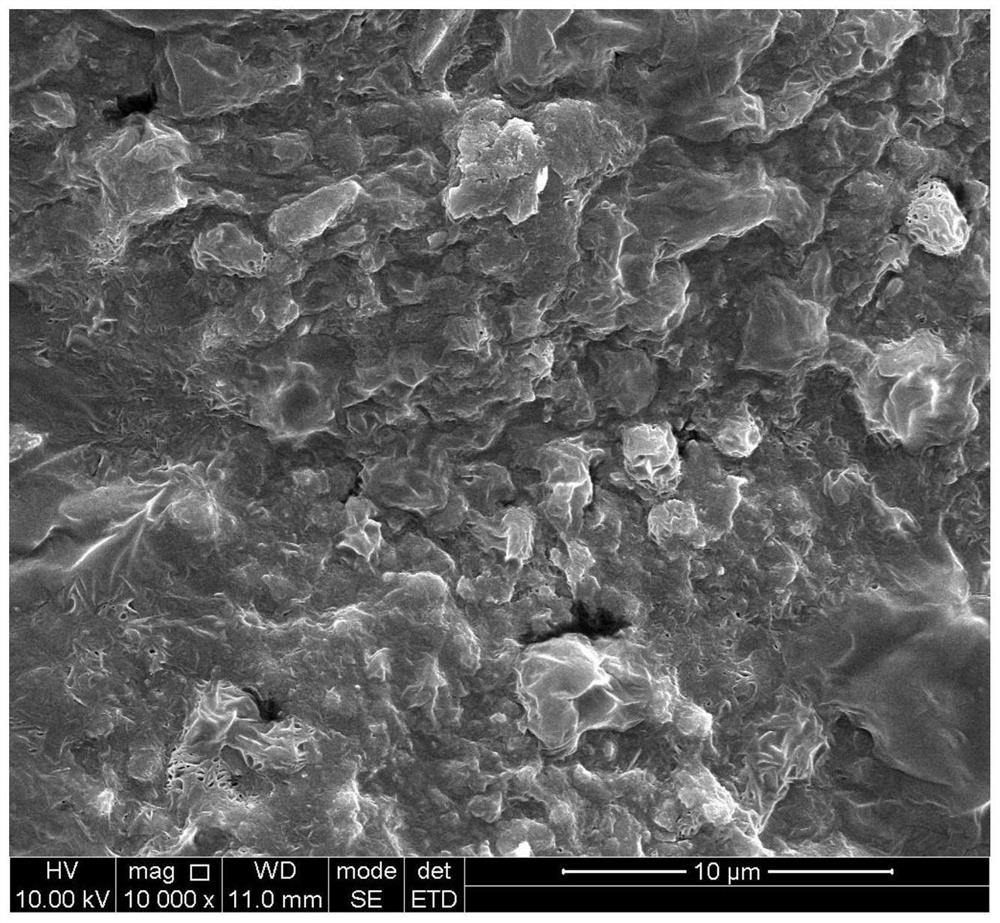

[0029] The shape-memory polyurethane bone scaffold material prepared by the gas foaming method provided in this example is composed of polyethylene glycol and amorphous calcium phosphate / calcium citrate composite powder. The content is 10%, and the rest is polyethylene glycol; the amorphous calcium phosphate is the precursor of hydroxyapatite, the calcium citrate is calcium citrate tetrahydrate, and the molecular weight of the polyethylene glycol is 4000. The specific implementation steps are as follows:

[0030] (1) take polyethylene glycol and amorphous calcium phosphate / calcium citrate with electronic balance;

[0031] (2) Add polyethylene glycol (40g) and amorphous calcium phosphate / calcium citrate (4.4g) with a mass ratio of 90 / 10 in a three-necked flask, add dichloromethane, and stir at 80°C;

[0032] (3) Stir for a certain period of time until the mixture is evenly stirred; the stirring speed is 300r / min;

[0033] (4) After mixing evenly, add 4.8ml of hexamethylene di...

Embodiment 2

[0044] The shape-memory polyurethane bone scaffold material prepared by the gas foaming method provided in this example is composed of polyethylene glycol and amorphous calcium phosphate / calcium citrate composite powder. In terms of mass percentage, the content of amorphous calcium phosphate / calcium citrate composite powder 20%, and the rest is polyethylene glycol; amorphous calcium phosphate is the precursor of hydroxyapatite, calcium citrate is calcium citrate tetrahydrate, and the molecular weight of polyethylene glycol is 4000. The specific implementation steps are as follows:

[0045] (1) take polyethylene glycol and amorphous calcium phosphate / calcium citrate with electronic balance;

[0046] (2) Add polyethylene glycol (40g) and amorphous calcium phosphate / calcium citrate (10g) with a mass ratio of 80 / 20 in a three-necked flask, add dichloromethane, and stir at 80°C;

[0047] (3) Stir for a certain period of time until the mixture is evenly stirred; the stirring speed ...

Embodiment 3

[0055] The shape-memory polyurethane bone scaffold material prepared by the gas foaming method provided in this example is composed of polyethylene glycol and amorphous calcium phosphate / calcium citrate composite powder. In terms of mass percentage, the content of amorphous calcium phosphate / calcium citrate composite powder 30%, and the rest is polyethylene glycol; amorphous calcium phosphate is the precursor of hydroxyapatite, calcium citrate is calcium citrate tetrahydrate, and the molecular weight of polyethylene glycol is 4000. The specific implementation steps are as follows:

[0056] (1) take polyethylene glycol and amorphous calcium phosphate / calcium citrate with electronic balance;

[0057] (2) Add polyethylene glycol (40g) and amorphous calcium phosphate / calcium citrate (16.67g) with a mass ratio of 70 / 30 in a three-necked flask, add dichloromethane, and stir at 80°C;

[0058] (3) Stir for a certain period of time until the mixture is evenly stirred; the stirring spe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com