A kind of preparation method of hydroxyanthraquinone extracorporeal circulation modified membrane

The technology of hydroxyanthraquinone body and hydroxyanthraquinone, which is applied in the field of medicine, can solve the problem of high hemolysis rate, and achieve the effects of reducing hemolysis reaction, avoiding the risk of organ damage and simple steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

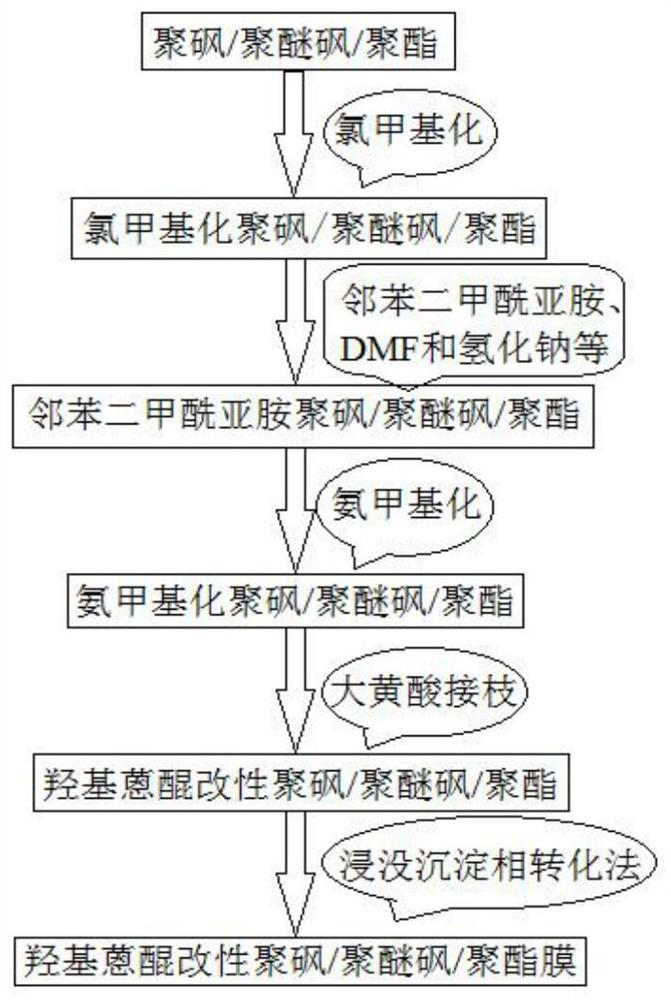

[0026] Such as figure 1 As shown, the invention provides a kind of preparation method of hydroxyanthraquinone extracorporeal circulation modified membrane, comprising the following steps:

[0027] S1: Preparation of chloromethylated polysulfone / polyethersulfone / polyester;

[0028] S2: Preparation of aminomethylated polysulfone / polyethersulfone / polyester;

[0029] S3: Preparation of hydroxyanthraquinone modified polysulfone / polyethersulfone / polyester membrane:

[0030] Further, the preparation method of chloromethylated polysulfone / polyethersulfone / polyester in the step S1 is as follows: first dissolve polysulfone / polyethersulfone / polyester in chloroform, then add paraformaldehyde and tetrachloride Fully react the tin oxide to form a complex, then add the chlorine agent trimethylchlorosilane and seal with nitrogen; mix well and put it in a 60°C water bath to complete the stirring reaction for 48-72h; then filter the reactant and wash it with absolute ethanol 3 times; finally...

Embodiment 1

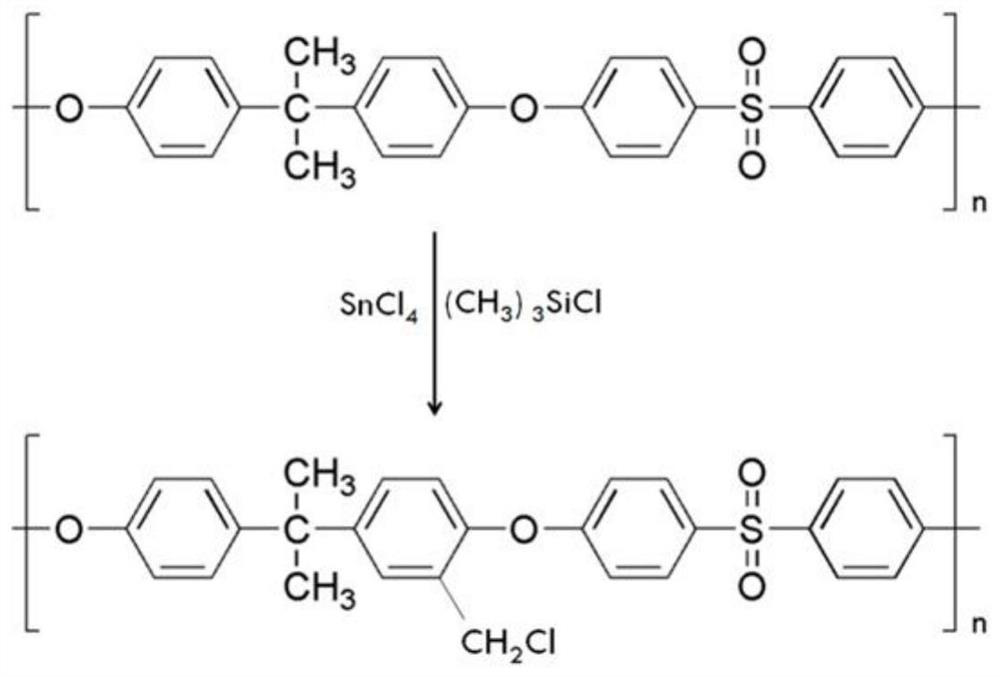

[0034] Step S1: The reaction principle is as follows figure 2 As shown, first dissolve 10g of polysulfone in 250ml of chloroform, then add 0.67g of paraformaldehyde and 0.26ml of tin tetrachloride to fully react to form a complex, then add 11.4ml of chlorine agent trimethylchlorosilane and seal with nitrogen; After mixing evenly, put it in a water bath at 60°C to complete the stirring reaction for 48 hours; then filter the reactant and wash it with absolute ethanol three times; and finally place it in a vacuum oven at 70°C for 24 hours to obtain chloromethylated polysulfone.

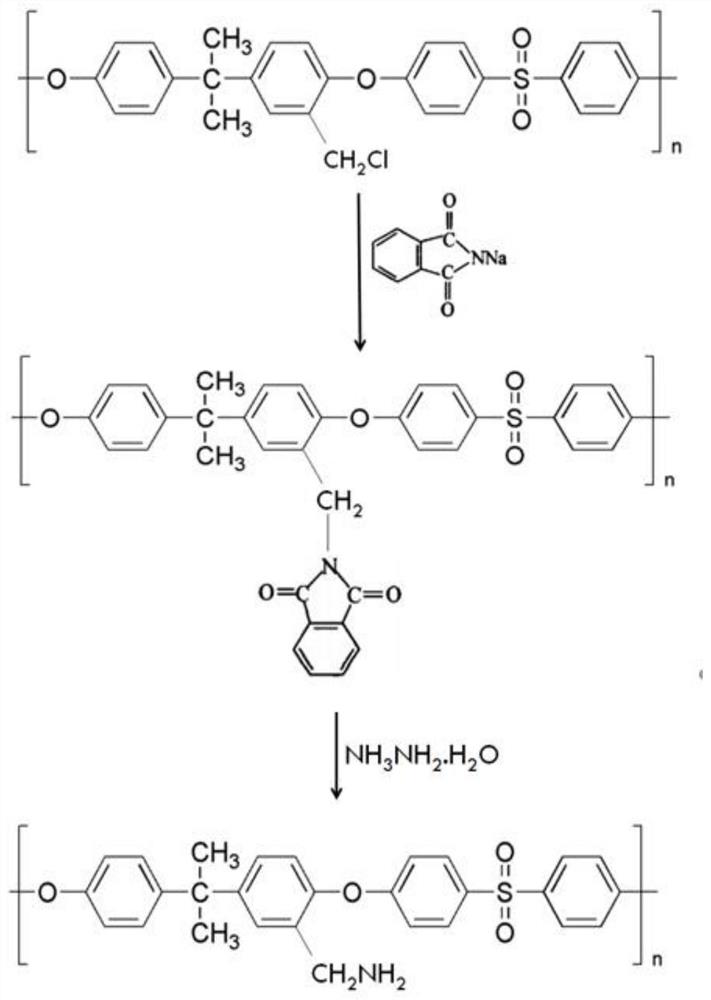

[0035] Step S2: The reaction principle is as follows image 3 As shown, dissolve 10g of chloromethylated polysulfone in 100ml of DMF, then pour the prepared phthalimide, DMF solution of chloromethylated polysulfone and sodium hydride mixture into a three-necked flask, wherein The mass volume ratio of phthalimide, DMF solution of chloromethylated polysulfone and sodium hydride is 7.4g: 100ml: 1.2g, heat...

Embodiment 2

[0038] Step S1: Dissolve 10g of polysulfone in 250ml of chloroform, then add 6.7g of paraformaldehyde and 0.52ml of tin tetrachloride to fully react to form a complex, then add 28.5ml of chlorine agent trimethylchlorosilane and nitrogen seal; After mixing evenly, put it in a water bath at 60°C to complete the stirring reaction for 72 hours; then filter the reactant and wash it with absolute ethanol three times; and finally dry it in a vacuum oven at 70°C for 24 hours to obtain chloromethylated polysulfone.

[0039] Step S2: Dissolve 10 g of chloromethylated polysulfone in 100 ml of DMF, then pour the prepared phthalimide, chloromethylated polysulfone in DMF solution and sodium hydride mixture into a three-necked flask, Among them, the mass volume ratio of phthalimide, chloromethylated polysulfone DMF solution and sodium hydride is 7.4g: 100ml: 1.5g, heated to reflux for 12h, cooled to room temperature, and precipitated the product with absolute ethanol , washed in distilled wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com