A deformed magnesium alloy plate with good strength and plasticity matching and its preparation method

A technology for deforming magnesium alloys and plates, which is applied in the field of metal plate rolling, can solve problems such as inability to adapt to industrial applications, inability to prepare high-performance magnesium alloy plates, and reduced strength of mechanical properties, so as to facilitate large-scale industrial applications and facilitate Good effect on storage and transportation, strength and plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

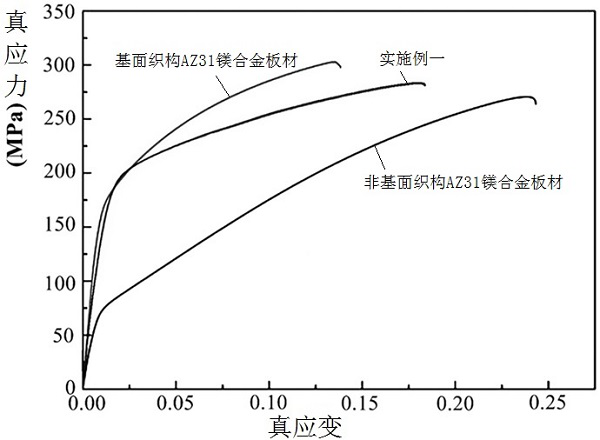

[0027] Embodiment 1, a method for preparing a wrought magnesium alloy plate with good strength and plasticity matching, which includes the following steps:

[0028] S1, cryogenic treatment + low speed rolling + annealing;

[0029] S11, place the non-basal textured AZ31 magnesium alloy sheet in a liquid nitrogen environment for 0.5h cryogenic treatment, the initial thickness of the non-basal textured AZ31 magnesium alloy sheet is 1.2mm;

[0030] S12, immediately after the cryogenic treatment is completed, the plate is rolled at a low speed, the rolling deformation is 3%, and the rolling speed is 0.2m / s;

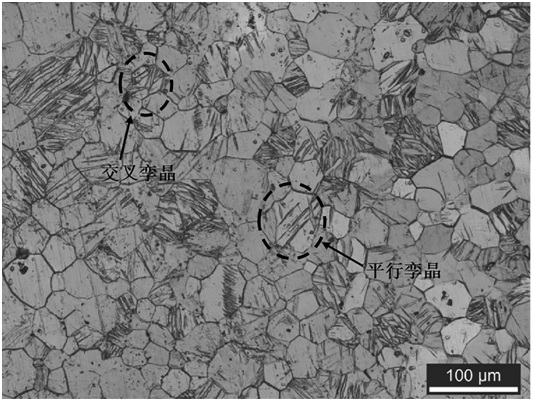

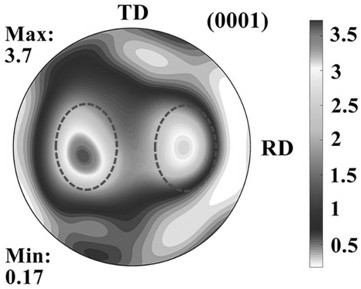

[0031] S13, put it in the air to return to room temperature naturally, and then perform recovery annealing treatment, the annealing temperature is 85°C, the annealing holding time is 0.5h, and then quenched. Through cryogenic treatment + low-speed rolling, a large number of dislocation motions are activated in the deformed magnesium alloy sheet with non-basal texture, and wit...

Embodiment 2

[0039]Embodiment 2, a method for preparing a deformed magnesium alloy plate with good strength and plasticity matching, which includes the following steps:

[0040] S1, cryogenic treatment + low speed rolling + annealing;

[0041] S11, place the non-basal textured AZ61 magnesium alloy sheet in a liquid nitrogen environment for cryogenic treatment for 1 hour, and the initial thickness of the non-basal textured AZ61 magnesium alloy sheet is 2.5mm;

[0042] S12, immediately after the cryogenic treatment is completed, the plate is rolled at a low speed, the rolling deformation is 4%, and the rolling speed is 0.4m / s;

[0043] S13, put it in the air to return to room temperature naturally, and then perform recovery annealing treatment, the annealing temperature is 100°C, the annealing holding time is 1h, and then quenched.

[0044] S2, cryogenic treatment + high speed rolling + annealing;

[0045] S21, placing the AZ61 magnesium alloy sheet treated in S1 in a liquid nitrogen envir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com