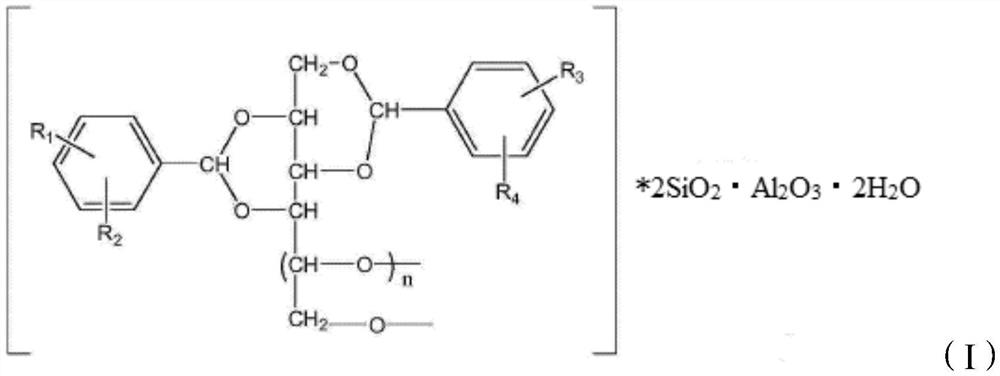

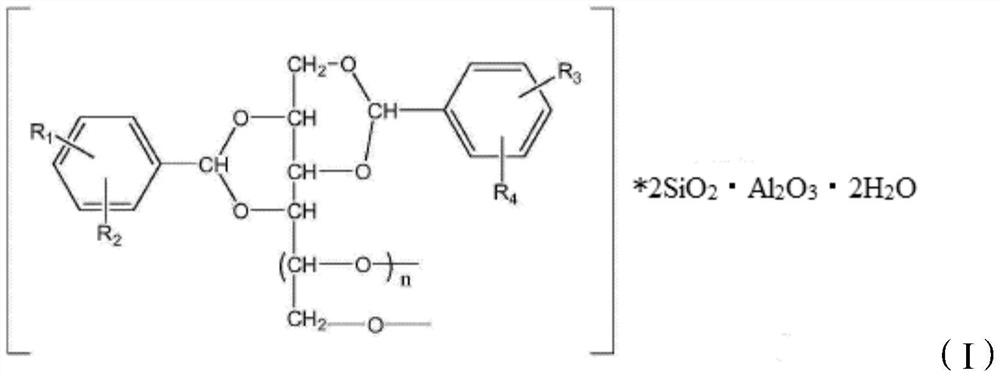

Chemical graft and its preparation method and use

A chemical grafting and compound technology, applied in the field of chemical grafting and its preparation, can solve the problems of high cost, increase cost, and the tensile yield stress needs to be increased, and achieve the effect of reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037]

[0038] The preparation method of the chemical graft of the present invention comprises the following steps: mixing the polyol with an organic solvent to form a first mixture; mixing the first mixture with an aromatic aldehyde to form a second mixture; mixing the second mixture with a catalyst and kaolin , forming a third mixture; reacting the third mixture at 20-80° C. for 2-10 hours to obtain a reaction solution; adjusting the pH of the reaction solution to be greater than or equal to 10 to terminate the reaction, and obtain a chemical graft after post-treatment.

[0039] In the present invention, the polyol may be selected from sorbitol, xylitol or glucose. According to one embodiment of the invention, the polyol is sorbitol.

[0040] The organic solvent can be selected from one or more of monovalent hydrocarbon alcohols, saturated aliphatic ethers, and chlorinated hydrocarbons. Examples of monohydric hydrocarbyl alcohols include, but are not limited to, methanol...

Embodiment 1

[0055] 18.2 g of sorbitol were dissolved in 100 mL of methanol to form a first mixture. Under stirring, the first mixture and 28.3 g of 3,4-dimethylbenzaldehyde were mixed to form a second mixture. Under stirring, the second mixture, 1 g of p-toluenesulfonic acid, and 2.5 g of activated kaolin were mixed to form a third mixture. Under stirring, the third mixture was reacted at 50° C. for 7 h to obtain a reaction liquid. Adjust the reaction liquid with aqueous sodium hydroxide solution to pH greater than or equal to 10, add tap water to wash, filter, and dry to obtain the chemical graft (additive 1) of the present invention.

Embodiment 2

[0057] 18.2 g of sorbitol were dissolved in 100 mL of methanol to form a first mixture. Under stirring, the first mixture and 26.4 g of p-chlorobenzaldehyde were mixed to form a second mixture. Under stirring, the second mixture, 0.9 g of concentrated sulfuric acid (95% by weight concentration) and 2.4 g of activated kaolin were mixed to form a third mixture. Under stirring, the third mixture was reacted at 60° C. for 7 h to obtain a reaction solution. Adjust the reaction liquid with sodium carbonate aqueous solution to pH greater than or equal to 10, add tap water to wash, filter, and dry to obtain the chemical graft (additive 2) of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com