Biodegradable polystyrene composition and preparation method thereof

A technology of biodegradation and polystyrene, applied in the field of biodegradable polystyrene composition and its preparation, can solve the problems of incomplete degradation of waste polystyrene, carbon deposition in heat transfer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

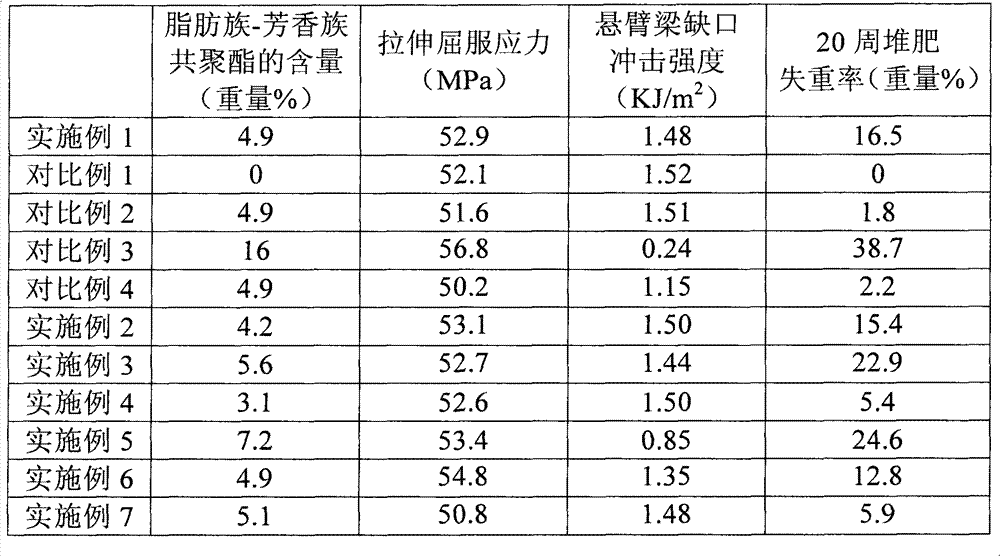

Examples

Embodiment 1

[0045] With 72g butylene terephthalate-co-butylene adipate copolyester (PBTA) (weight average molecular weight is 1.1 * 10 5 , aliphatic content is 75 mol%, biodegradation rate is 60% (composting in 87 days), purchased from BASF company) joins in 200g ethylbenzene, heats in boiling water bath, stirs 2 hours and makes PBTA dissolve completely.

[0046]The air in the kettle was completely replaced with nitrogen; 1700g of styrene monomer (produced by Yanshan Petrochemical) and 100g of ethylbenzene were added to the kettle, and 1.8g of anti-aging agent 1076 was added. The initiation method adopts thermal initiation. The polymerization kettle is heated at a stirring rate of 138rpm / min, and the agitator is a ribbon compound agitator in the upper part of the bottom triangular plate; when the reaction temperature reaches 100°C, under the protection of nitrogen, the ethyl group of the completely dissolved PBTA Add the benzene solution into the reaction kettle and continue to heat up. ...

Embodiment 2

[0056] Add 60 g of PBTA into 200 g of ethylbenzene, heat in a boiling water bath, and stir for 2 hours to completely dissolve the PBTA.

[0057] The air in the kettle was completely replaced with nitrogen; 1700g of styrene monomer (produced by Yanshan Petrochemical) and 500g of ethylbenzene were added to the kettle, and 1.8g of anti-aging agent 2246 was added. The reaction was initiated by adding 2 g of cumene hydroperoxide. The polymerization kettle is heated up at a stirring rate of 125rpm / min, and the agitator is a ribbon compound agitator in the upper part of the bottom triangular plate; Add the benzene solution into the reaction kettle and continue to heat up. Polymerization was carried out at 105°C for 5 hours, at 135°C for 2.5 hours, and at 140°C for 2 hours. After the polymerization is completed, the viscous body obtained from the polymerization is discharged, placed in a devolatilizer at 195°C, and flashed rapidly under vacuum to remove unreacted styrene monomer and...

Embodiment 3

[0059] 85g of hexanediol terephthalate-co-hexanediol adipate copolyester (PHTA, purchased from BASF, with a weight average molecular weight of 1.2×10 5 , the aliphatic content is 85 mole %), add in 200g ethylbenzene, heat in boiling water bath, stir 3 hours and make PHTA dissolve completely.

[0060] The air in the kettle was completely replaced with nitrogen; 1700 g of styrene monomer (produced by Yanshan Petrochemical) and 300 g of ethylbenzene were added into the kettle. The initiation method adopts thermal initiation. The polymerization kettle is heated at a stirring rate of 130rpm / min, and the agitator is a ribbon compound agitator in the upper part of the bottom triangular plate; when the reaction temperature reaches 100°C, under the protection of nitrogen, the ethyl group of the completely dissolved PHTA Add the benzene solution into the reaction kettle and continue to heat up. Polymerization was carried out at 130°C for 3 hours, at 140°C for 1.5 hours, and at 170°C f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com