Method for improving binding force of Ti-Al coating on surface of TA15 titanium alloy and prepared coating

A technology of titanium alloy and bonding force, which is applied in the coating process and coating of metal materials, can solve the problems of easy peeling off of the coating and other comprehensive properties, and achieve the solution of easy peeling off of the coating, improvement of hardness and wear resistance, and improvement of coating quality. The effect of layer organization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

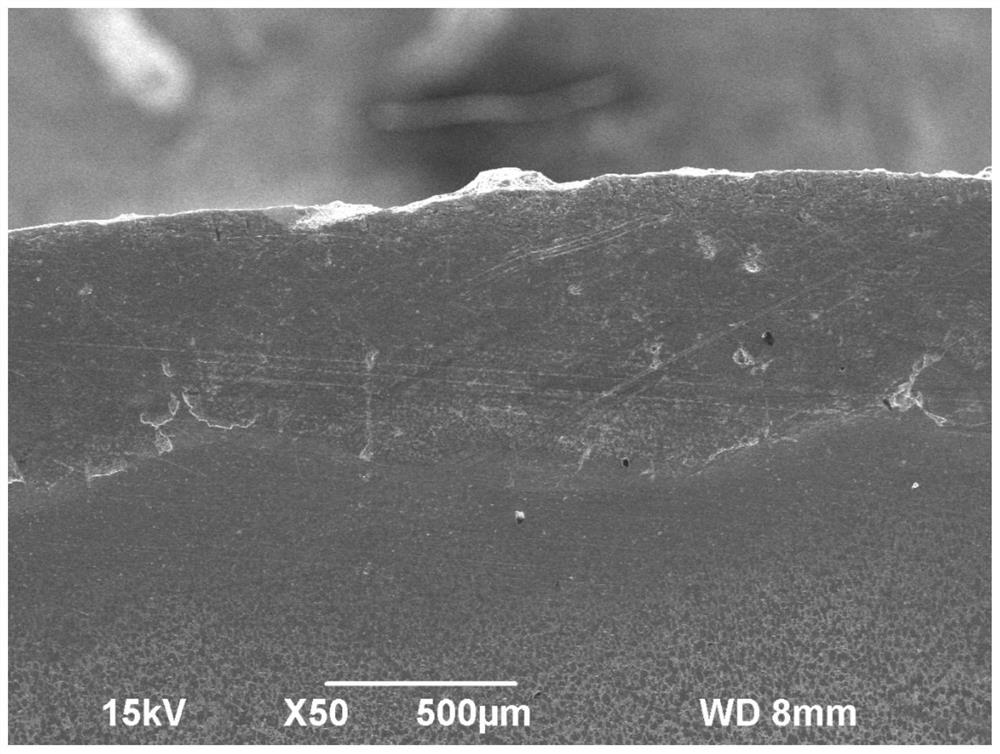

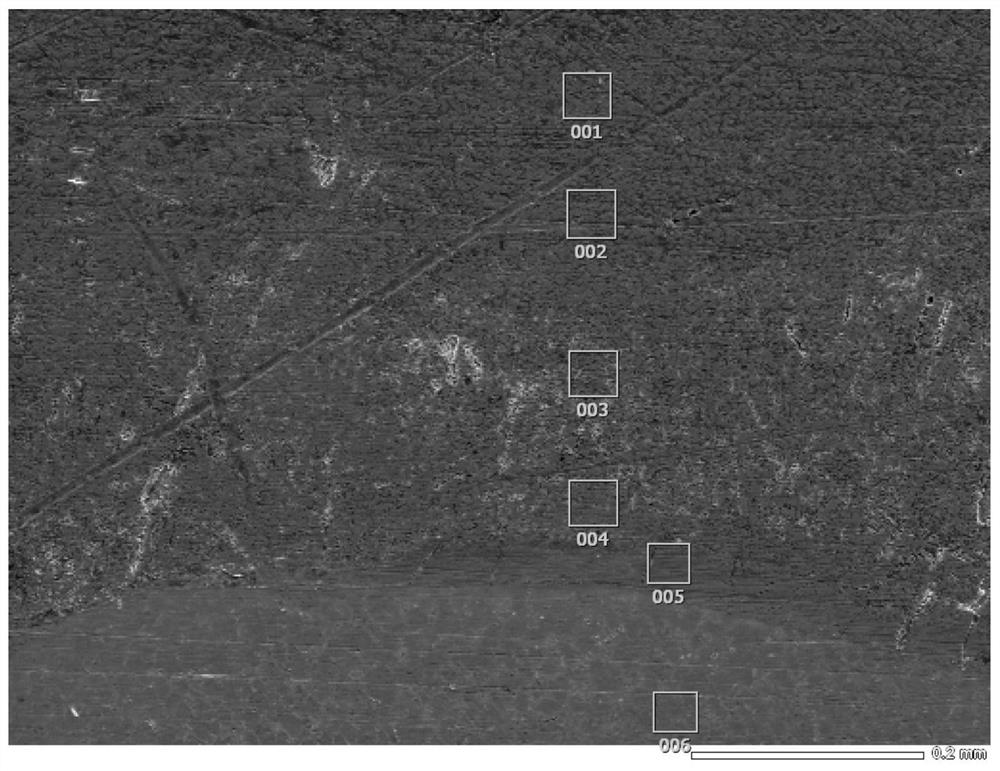

[0029] Such as Figure 1-2 As shown, the present embodiment provides a method for improving the bonding force of the Ti-Al coating on the surface of the TA15 titanium alloy and the prepared coating, the method comprising the following steps:

[0030] (1) Cut the TA15 titanium alloy into blocks of 10mm×10mm×8mm, then polish and grind it, and use analytically pure grade acetone, hydrochloric acid, ethanol and deionized water to ultrasonically clean the titanium alloy for 8 minutes to obtain pretreated titanium alloy;

[0031] (2) The ZL116 alloy is made into powder with an average size of 75 μm;

[0032] (3) The surface of the pretreated titanium alloy obtained in step (1) is carried out by laser cladding with the ZL116 alloy powder to form a titanium-aluminum compound by adopting the method of coaxial powder feeding under argon protection, and then air-cooled to obtain a high-strength coating on the surface of the titanium alloy. layer, use sandpaper to polish the pure alumin...

Embodiment 2

[0039] The present embodiment provides a method for improving the Ti-Al coating binding force on the surface of TA15 titanium alloy and the prepared coating, the method comprising the following steps:

[0040] (1) Cut the TA15 titanium alloy into blocks of 10mm×10mm×8mm, then polish and grind it, and use analytically pure grade acetone, hydrochloric acid, ethanol and deionized water to ultrasonically clean the titanium alloy for 9 minutes to obtain pretreated titanium alloy. alloy;

[0041] (2) The ZL116 alloy is made into powder with an average size of 75 μm;

[0042] (3) The surface of the pretreated titanium alloy obtained in step (1) is carried out by laser cladding with the ZL116 alloy powder to form a titanium-aluminum compound by adopting the method of coaxial powder feeding under argon protection, and then air-cooled to obtain a high-strength coating on the surface of the titanium alloy. layer, use sandpaper to polish the pure aluminum layer on the outer surface of th...

Embodiment 3

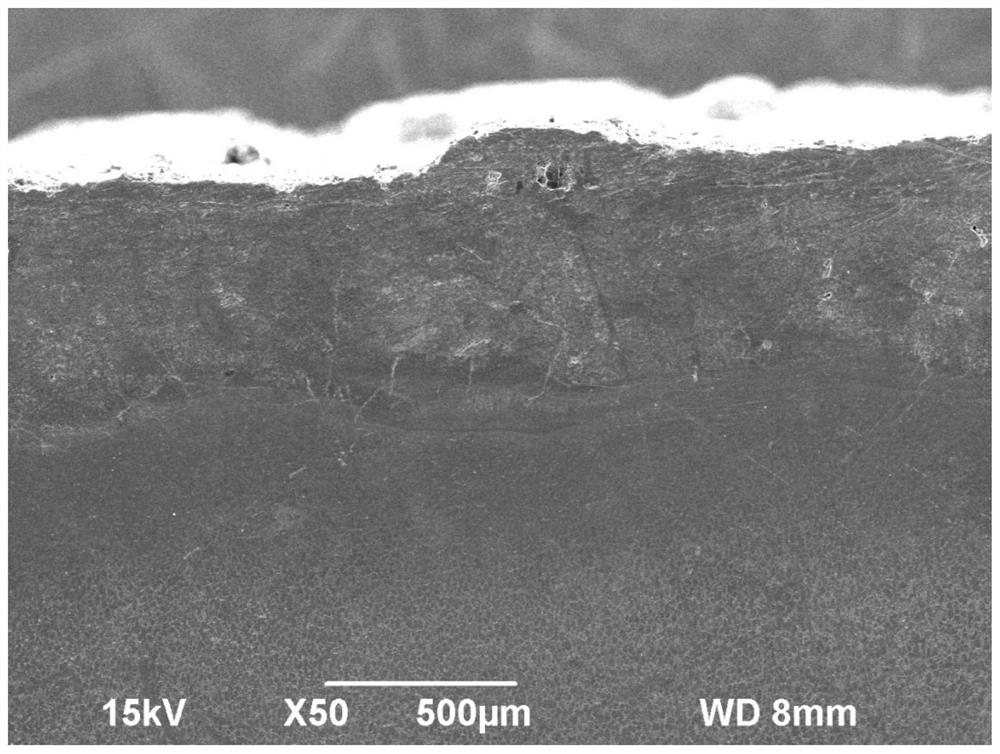

[0044] The present embodiment provides a method for improving the Ti-Al coating binding force on the surface of TA15 titanium alloy and the prepared coating, the method comprising the following steps:

[0045] (1) Cut the TA15 titanium alloy into blocks of 10mm×10mm×8mm, then polish and grind it, and use analytically pure grade acetone, hydrochloric acid, ethanol and deionized water to ultrasonically clean the titanium alloy for 8 minutes to obtain pretreated titanium alloy;

[0046] (2) The ZL116 alloy is made into powder with an average size of 75 μm;

[0047] (3) The surface of the pretreated titanium alloy obtained in step (1) is carried out by laser cladding with the ZL116 alloy powder to form a titanium-aluminum compound by adopting the method of coaxial powder feeding under argon protection, and then air-cooled to obtain a high-strength coating on the surface of the titanium alloy. layer, use sandpaper to polish the pure aluminum layer on the outer surface of the coati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com