High-strength high-temperature-resistant epoxy floor coating and preparation method thereof

A technology of epoxy flooring and high temperature resistance, which is applied in the direction of epoxy resin coatings, fireproof coatings, coatings, etc., and can solve the problem of reducing the flame retardant effect of epoxy floor coatings, long-term service performance, and interface bonding of epoxy floor coatings Insufficient strength, difficult to guarantee the dispersion effect of flame retardants, etc., to achieve ideal effects of improving antistatic effect, improving interface compatibility, and heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

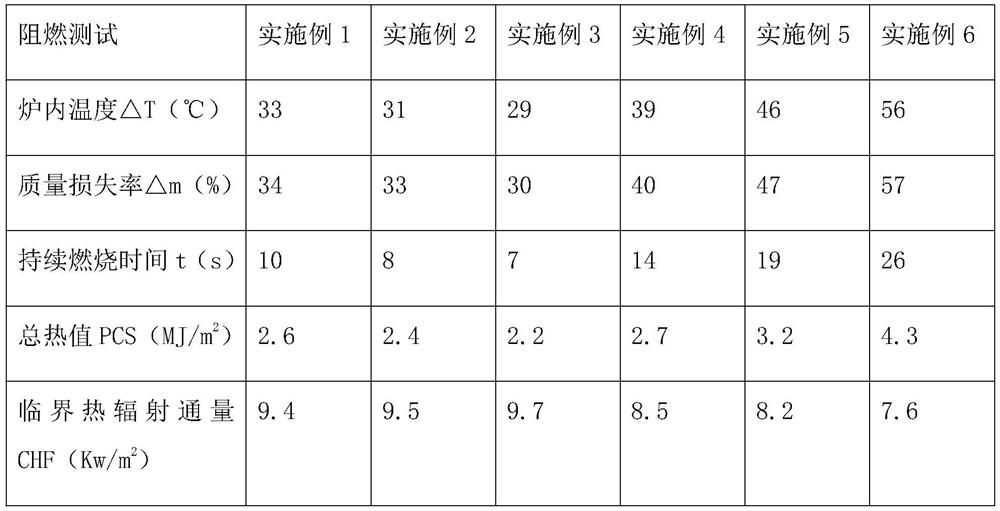

Examples

Embodiment 1

[0042] Step 1: Filler pretreatment:

[0043] A. Mix quartz powder, glass powder, cement powder, and water in a mass ratio of 1:15:1:4 to obtain filler;

[0044] B. Put 40 parts of hydroxysilane coupling agent in 130 parts of methanol solution, stir and disperse, add 20 parts of filler, ultrasonically oscillate at an oscillation frequency of 20 kHz for 30 minutes, and filter to obtain material A;

[0045] Step 2: Synthesis of polymerized monomer solution:

[0046] A. Add 2-carboxyethylphenyl hypophosphorous acid into distilled water, stir until completely dissolved to obtain solution A, then add 10 parts of sulfuric acid solution to 100 parts of solution A, and heat the temperature to 50°C at a certain heating rate, Keep constant temperature, reflux and stir for 15 minutes, after the reaction, place it under low temperature for 20 minutes to obtain solution B;

[0047] B. Keeping the low temperature reaction conditions unchanged, add 15 parts of 3,4-ethylenedioxythiophene to ...

Embodiment 2

[0055] Step 1: Filler pretreatment:

[0056] A. Mix quartz powder, glass powder, cement powder, and water in a mass ratio of 4:15:1:4 to obtain filler;

[0057] B. Put 50 parts of hydroxysilane coupling agent in 140 parts of methanol solution to stir and disperse, add 25 parts of filler, ultrasonically oscillate at an oscillation frequency of 25 kHz for 40 minutes, and filter to obtain material A;

[0058] Step 2: Synthesis of polymerized monomer solution:

[0059] A. Add 2-carboxyethylphenyl hypophosphorous acid into distilled water, stir until completely dissolved to obtain solution A, then add 15 parts of sulfuric acid solution to 150 parts of solution A, heat the temperature to 60°C at a certain heating rate, Keep constant temperature, reflux and stir for 20 minutes, after the reaction, place it under low temperature for 25 minutes to obtain solution B;

[0060] B. Keeping the low temperature reaction conditions unchanged, add 20 parts of 3,4-ethylenedioxythiophene to th...

Embodiment 3

[0068] Step 1: Filler pretreatment:

[0069] A. Mix quartz powder, glass powder, cement powder, and water in a mass ratio of 8:15:1:4 to obtain filler;

[0070] B. Put 60 parts of hydroxysilane coupling agent in 150 parts of methanol solution, stir and disperse, add 30 parts of filler, ultrasonically oscillate at an oscillation frequency of 30 kHz for 50 minutes, and filter to obtain material A;

[0071] Step 2: Synthesis of polymerized monomer solution:

[0072] A. Add 2-carboxyethylphenyl hypophosphorous acid into distilled water, stir until completely dissolved to obtain solution A, then add 20 parts of sulfuric acid solution to 200 parts of solution A, and heat the temperature to 70°C at a certain heating rate, Keep constant temperature, reflux and stir for 25 minutes, after the reaction, place it under low temperature for 30 minutes to obtain solution B;

[0073] B. Keeping the low temperature reaction conditions unchanged, add 25 parts of 3,4-ethylenedioxythiophene to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com