Preparation method of fine indium sulfide powder and target material

A technology of indium sulfide and powder, which is applied in the field of solar cell materials, can solve the problems of unfavorable grain size, large powder particle size, and small density, and achieve uniform resistivity, high density, and reduced grain size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method of preparing a fine sulfide oxide powder, steps below:

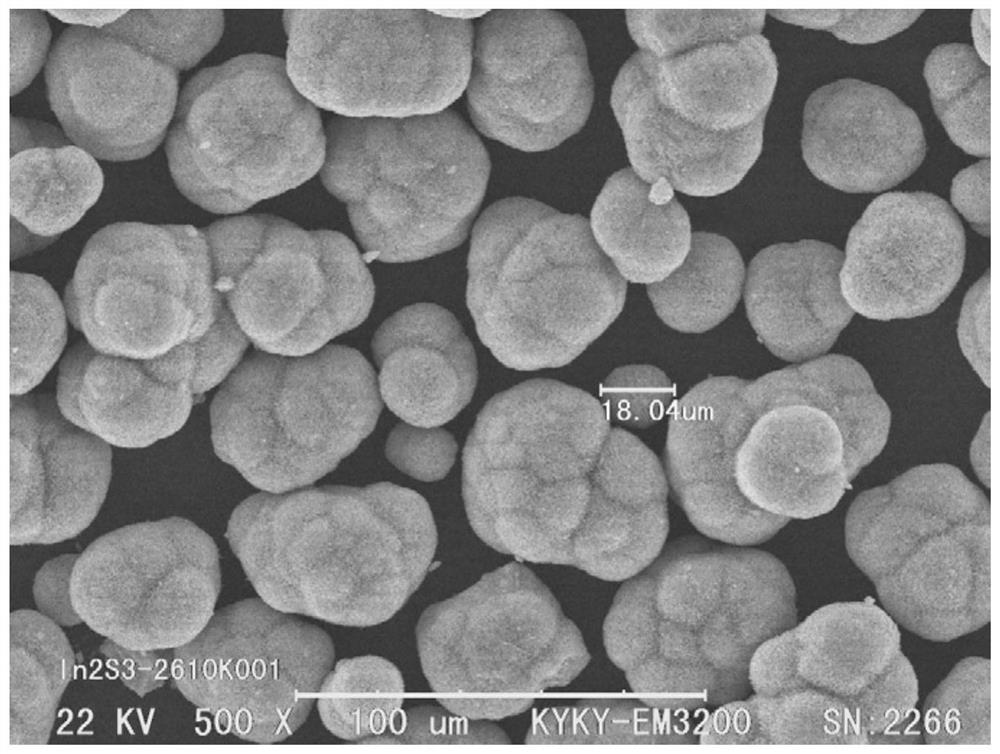

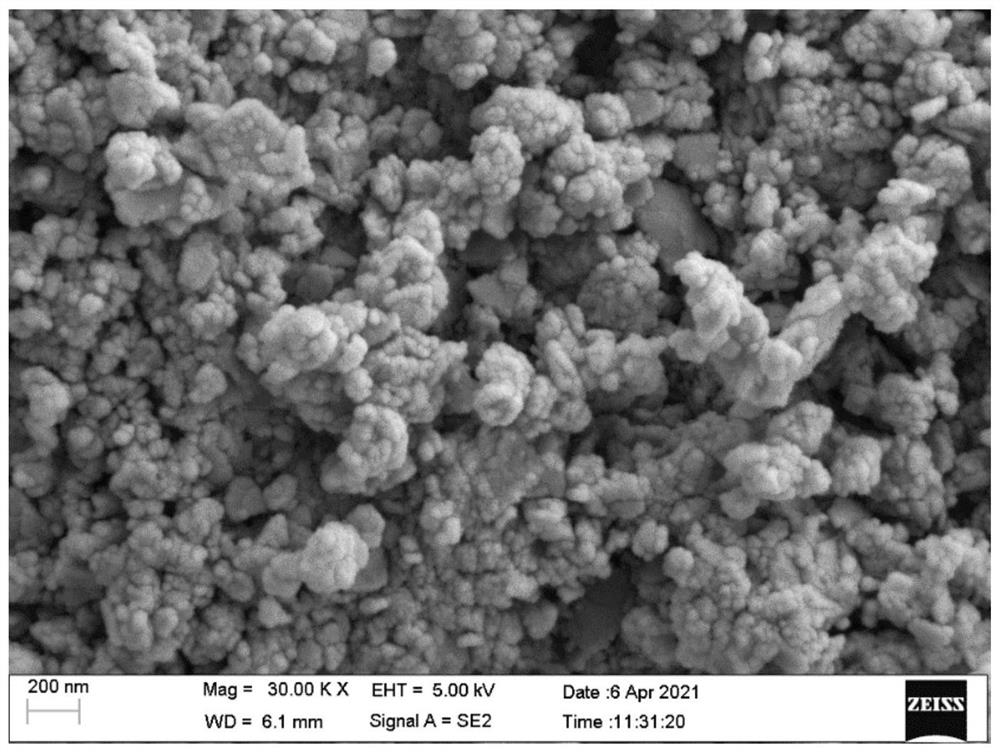

[0032] Be in 3+ IN in the concentration of 100 g / L 2 (SO4) 3 The solution was added to the glass reaction kettle, and the stirring paddle was opened, and the mixing paddle rate was controlled at 200 rpm. Then, will h 2 The S gas is entry in the flow of 2 L / min. 2 (SO4) 3 In the solution until the reaction is completed. Then, the pure water is rinsed, and the cycle is filtered multiple times until the liquid in the reactor is not turbid. Take the sulfurized indium moisture in the filter bag, place in a clean quartz booon, then add the calcination in the quartz force, the calcination temperature is 450 ° C, heat insulation 120min, cool to room temperature, discharge. The material was placed in the ball grinding 10 min, and then sieved with a 325 mesh stainless steel screen to give indium oxide powder. Sampling, XRD and SEM analysis of sulfide sulfide powder, analysis results figure 1 and figure 2 .

[0033]...

Embodiment 2

[0036] A method of preparation of indium sulfide targets, as follows:

[0037] The fine sulfide produced in Example 1 was laid into the graphite mold, and then the graphite mold was placed in a vacuum hot press. First, the preload is performed at 2T / min to 10 MPa to exclude the air in the graphite mold, and the pressure is charged for 3 minutes to obtain an indium oxide billet. Then, when the furnace door is closed, the vacuum is vacumed to a vacuum to 5PA, start heating, warming up at 5 ° C / min to 700 ° C, heat insulation 120min; wherein the holding is 20 min, pressurize, pressurized to 30 MPa After 40 min, after the insulation is complete, slow down to 10 MPa until the insulation is over. Finally, the burner door is opened, the fireplace door is opened, and the indium sulfide blank target is obtained. The sulfide indium blank target is processed into the desired size to obtain an indium oxide target.

[0038] Density, resistivity, and crystal particle size detection of indiu...

Embodiment 3

[0040] A method of preparing a fine sulfide oxide powder, steps below:

[0041] Be in 3+ Ins with a concentration of 200g / L 2 (SO4) 3 The solution was added to the glass reaction kettle, and the stirring paddle was opened, and the stirring paddle rate was controlled at 300 rpm. Then, will h 2 S gas is entry in 3L / min 2 (SO4) 3 In the solution until the reaction is completed. Then, the pure water is rinsed, and the cycle is filtered multiple times until the liquid in the reactor is not turbid. Take the sulfurized indium moisture in the filter bag, place in a clean quartz booon, then add the calcination in the quartz force, the calcination temperature is 450 ° C, heat insulation 120min, cool to room temperature, discharge. The material was placed in the ball grinding 10 min, and then sieved with a 325 mesh stainless steel screen to give indium oxide powder. Sampling, XRD and SEM analysis of the sulfide oxide powder, analysis results are analyzed as the analysis result of the ind...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com