Preparation method of ethyl benzoylacetate

A technology of ethyl benzoyl acetate and concentrated sulfuric acid, which is applied in the preparation of carboxylic acid esters, the preparation of organic compounds, the separation/purification of carboxylic acid esters, etc., can solve the problems of surface corrosion and affecting filtration efficiency, and achieve enhanced durability Corrosiveness, the effect of guaranteeing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

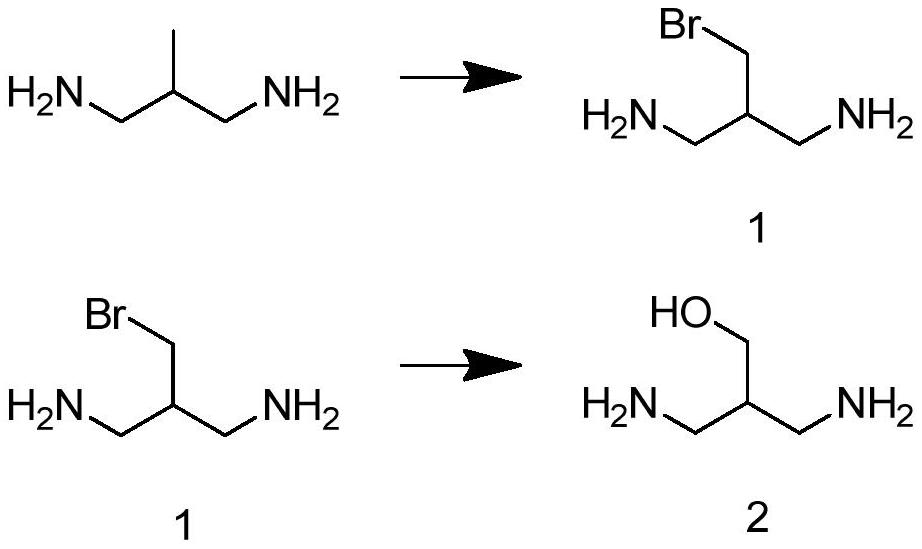

Method used

Image

Examples

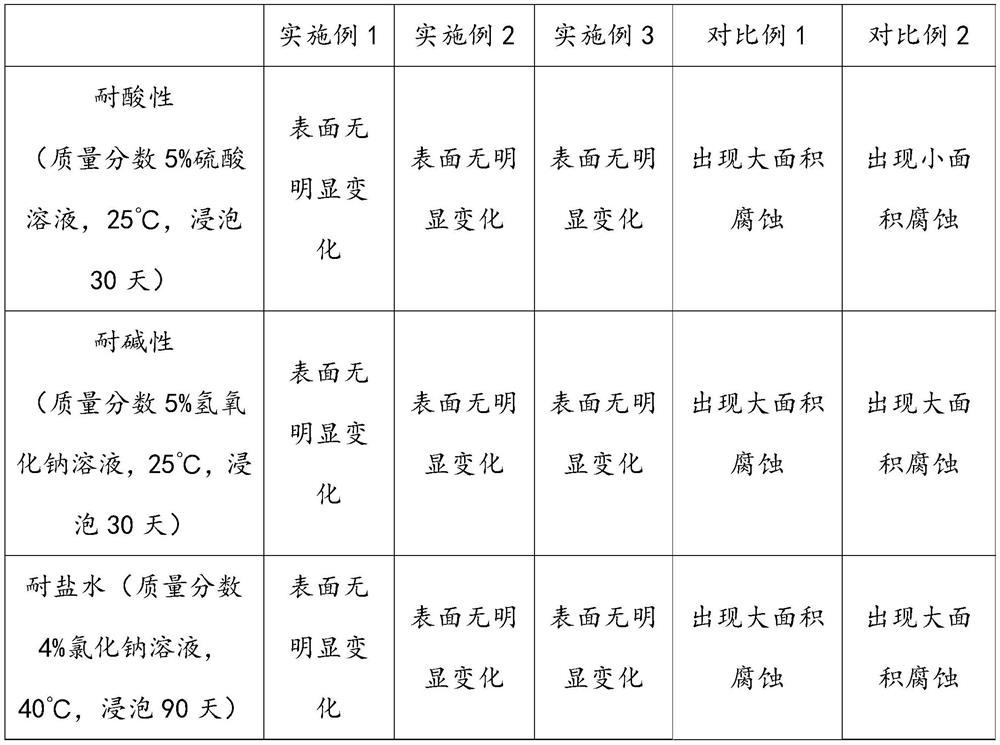

Embodiment 1

[0029] The preparation method of ethyl benzoyl acetate comprises the steps:

[0030] Step S1: Add carbon tetrachloride and sodium bicarbonate into the reaction kettle, stir at a speed of 150r / min, and a temperature of 15°C, and add ethyl acetoacetate, after stirring for 10 minutes, add benzoyl chloride, The temperature was raised to 50°C, and the reaction was continued for 3 hours;

[0031] Step S2: Add sodium hydroxide to the reaction kettle, and react for 10 hours at a speed of 200r / min and a temperature of 100°C, then cool down to a temperature of 25°C, filter with a microporous membrane, and filter the filtrate Distillation to obtain ethyl benzoylacetate.

[0032] Described microporous membrane is made by following steps:

[0033] After mixing polypropylene, kerosene, and reinforcing fillers uniformly, blend and extrude at a temperature of 40°C. The temperature of the roller is 190°C, the linear speed of the roller is 25m / min, and the speed difference between the upper a...

Embodiment 2

[0040] The preparation method of ethyl benzoyl acetate comprises the steps:

[0041] Step S1: Add carbon tetrachloride and sodium bicarbonate into the reaction kettle, stir at a rotation speed of 150r / min, and a temperature of 25°C, and add ethyl acetoacetate, after stirring for 10 minutes, add benzoyl chloride, The temperature was raised to 60°C, and the reaction was continued for 3 hours;

[0042] Step S2: Add sodium hydroxide to the reaction kettle, and carry out the reaction for 15 hours under the condition of rotating speed of 300r / min and temperature of 100°C, then cool down to a temperature of 25°C, filter with a microporous membrane, and filter the filtrate Distillation to obtain ethyl benzoylacetate.

[0043] Described microporous membrane is made by following steps:

[0044] After mixing polypropylene, kerosene, and reinforcing fillers uniformly, blend and extrude at a temperature of 60°C. The temperature of the roller is 190°C, the linear speed of the roller is 25...

Embodiment 3

[0051] The preparation method of ethyl benzoyl acetate comprises the steps:

[0052] Step S1: Add carbon tetrachloride and sodium bicarbonate into the reaction kettle, stir at a speed of 200r / min, and a temperature of 25°C, and add ethyl acetoacetate, after stirring for 15 minutes, add benzoyl chloride, The temperature was raised to 60°C, and the reaction was continued for 5 hours;

[0053] Step S2: Add sodium hydroxide to the reaction kettle, and carry out the reaction for 15 hours under the condition of the rotating speed of 300r / min and the temperature of 120°C, then cool down to the temperature of 30°C, filter with a microporous membrane, and filter the filtrate Distillation to obtain ethyl benzoylacetate.

[0054] Described microporous membrane is made by following steps:

[0055] After mixing polypropylene, kerosene, and reinforcing fillers evenly, blend and extrude at a temperature of 60°C. The temperature of the roller is 200°C, the linear speed of the roller is 25m / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com