Method for reducing content of deoxynivalenol in malting process

A technology of deoxynivalenol content, which is applied in botany equipment and methods, biochemical equipment and methods, chemicals for biological control, etc., can solve the problems of difficult utilization, low solubility of plant essential oils, heat resistance high stability issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

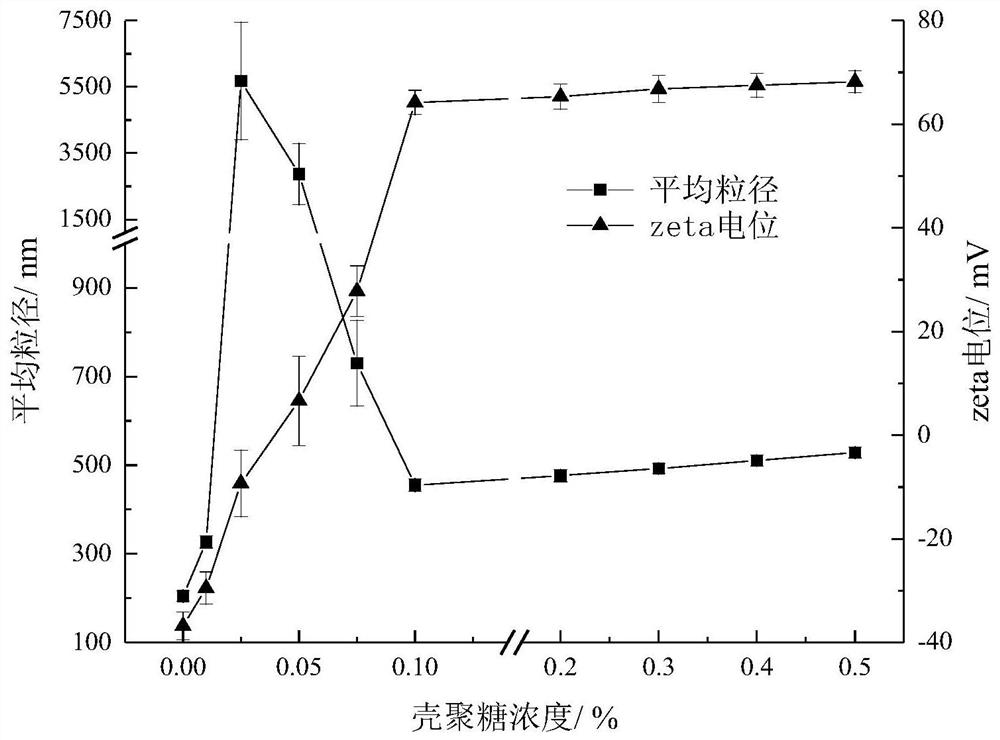

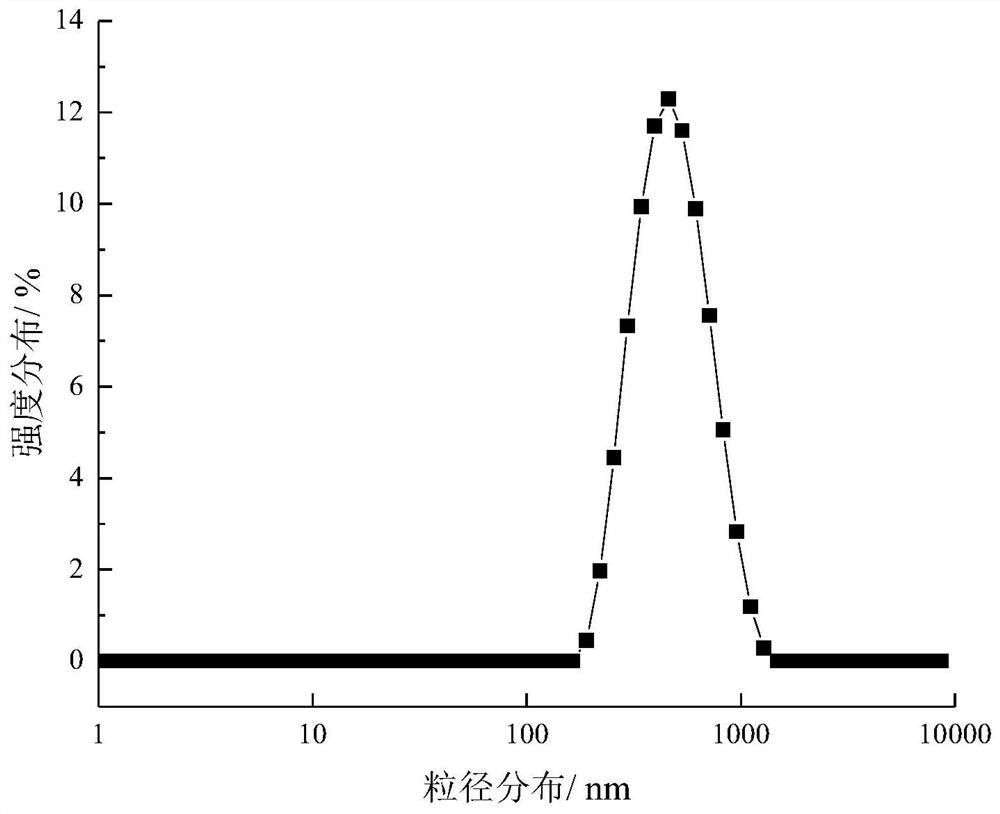

[0042] Embodiment 1 different chitosan concentrations prepare Litsea cubeba oil nanoemulsion

[0043] (1) Dissolve lecithin in 10mM acetate buffer solution to prepare a solution with a lecithin concentration of 10g / L, and filter through a double-layer filter cloth to obtain an emulsifier solution

[0044] (2) Mix 92mL of the emulsifier solution prepared in step (1) with 8mL of Litsea cubeba oil to obtain a total of 100mL of the mixed system. Use a hand-held homogenizer to homogenize at 32000rpm for 2min, then pass through a high-pressure homogenizer, Circulation and homogenization at a rate of 9 L / h for 1 min under a pressure of 1000 bar to obtain a primary emulsion of litsea cubeba oil.

[0045] (3) be that concentration is 0%, 0.5g / L, 1g / L, 2g / L, 3g / L, 4g / L, the chitosan solution of 5g / L and the litsea cubeba oil primary that step (2) prepares The emulsion was mixed at a mass ratio of 1:1, ultrasonicated at 40kHz, 300W for 30s, inverted and mixed for 30s, repeated 3 times a...

Embodiment 2

[0048] Embodiment 2 Litsea cubeba oil nanoemulsion inhibits the growth of Fusarium graminearum mycelium

[0049] (1) 100 μL of Litsea Cubeba Oil Primary Emulsion and Litsea Cubeba Oil Nanoemulsion prepared in Example 1 were respectively coated on a PDA plate, and an equal amount of acetic acid buffer was used as a blank control.

[0050] (2) Take the mycelium of Fusarium graminearum activated for 4 days on the plate, punch a fresh bacterium cake with a diameter of 6 mm, inoculate it in the center of the plate coated with emulsion in step (1), and cultivate it for 4 days at 27 ° C. The mycelial diameter was measured and the mycelial inhibition rate (MGI) was calculated.

[0051] MGI (%)=(blank mycelium diameter-sample mycelium diameter)×100%.

[0052] The inhibitory effects of different solutions on the mycelial growth of Fusarium graminearum were as follows: image 3 As shown, the MGI of Litsea cubeba oil primary emulsion to Fusarium graminearum mycelia is only 15.2%, while ...

Embodiment 3

[0053] Example 3 Effect of adding emulsion on DON content in malt at different stages of malting process

[0054] (1) Use malting barley infected with scab, with 200g barley as a group, carry out malting experiment:

[0055] Soak the wheat in a 1L beaker, use 500mL of soaking water each time, and cut off the water in the specially customized malt making tank. Wheat immersion process: the first immersion in water for 6 hours, water cut-off for 8 hours; the second immersion in water for 4 hours, water cut-off for 6 hours; the third immersion in water for 3 hours; the temperature of wheat immersion in the whole process is 13°C, the humidity is 95%, and the degree of immersion is controlled at 43%-45% ;

[0056] Germination: 0-24h at 14°C, 25-48h at 14.5°C, 49-120h at 15°C, turn the wheat twice a day, and replenish water once;

[0057] Baking: 57°C for 7h, 59°C for 2h, 61°C for 2h, 63°C for 2h, 65°C for 2h, 73°C for 2h, 77°C for 1h, 86°C for 3h.

[0058] (2) Add 100 g of Litsea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com