High-temperature-resistant anti-corrosion water-based coating and preparation method thereof

A water-based paint and anti-corrosion technology, applied in the field of paint, can solve the problem that solvent-based paint is not environmentally friendly, and achieve the effects of not easy to break, improve temperature resistance, and improve mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

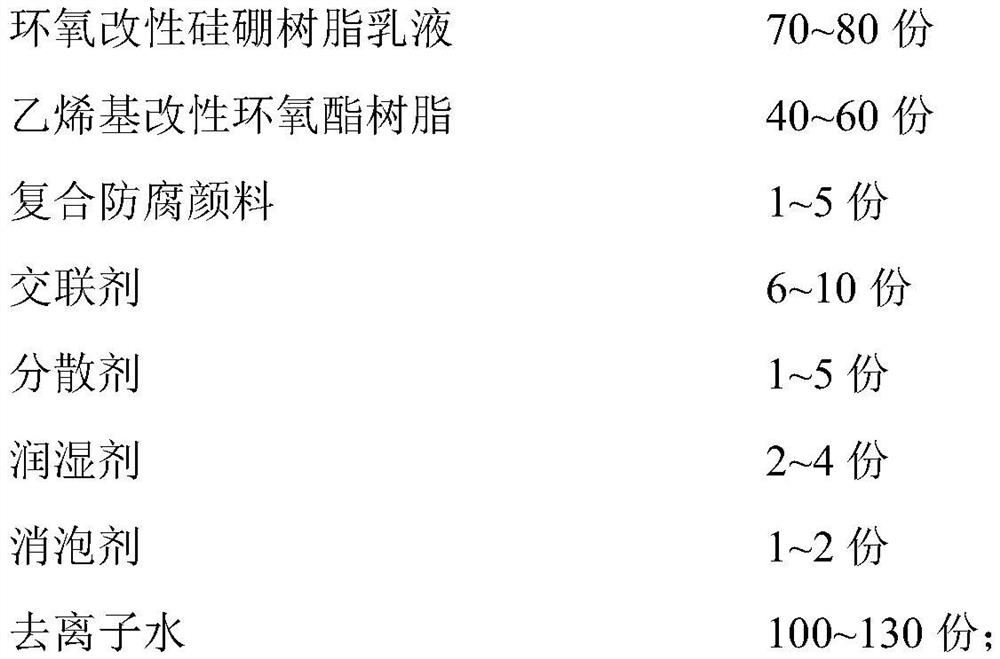

[0040] A high-temperature-resistant and anti-corrosion water-based paint, comprising the following raw materials in parts by weight:

[0041]

[0042] The composite anticorrosion pigment is a hydroxyl-terminated hyperbranched poly(amine-ester) modified graphene oxide / nano aluminum phosphate composite anticorrosion pigment.

[0043] In the present embodiment, the preparation method of the epoxy-modified silicon boron resin emulsion comprises the following steps:

[0044] S1. Mix 23 parts of n-butanol and 13 parts of cyclohexanone, add 75 parts of cyclopropane, and stir for 18 minutes at 40°C at a speed of 250 rpm / min to obtain a solution mixture;

[0045] S2. Add 70 parts of boric acid-modified silicone resin emulsion to 40 parts of epoxy resin, and stir at a speed of 225 rpm / min for 30 minutes in an oil bath at 60°C to obtain a mixed resin emulsion;

[0046] S3. Add the solution mixture obtained in S1 to the mixed resin emulsion obtained in S2, stir and react at a speed of 4...

Embodiment 2

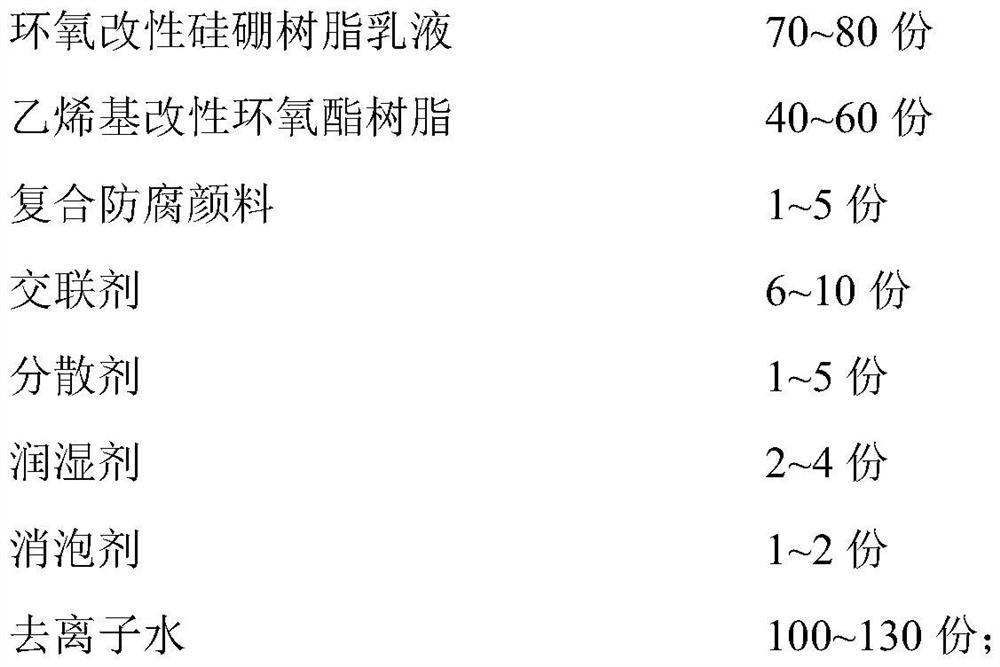

[0061] A high-temperature-resistant and anti-corrosion water-based paint, comprising the following raw materials in parts by weight:

[0062]

[0063] The composite anticorrosion pigment is a hydroxyl-terminated hyperbranched poly(amine-ester) modified graphene oxide / nano aluminum phosphate composite anticorrosion pigment.

[0064] In the present embodiment, the preparation method of the epoxy-modified silicon boron resin emulsion comprises the following steps:

[0065] S1. Mix 15 parts of n-butanol and 10 parts of cyclohexanone, add 50 parts of cyclopropane, and stir at 35°C for 15 minutes at a speed of 200 rpm / min to obtain a solution mixture;

[0066] S2. Add 30 parts of 50 parts of boric acid-modified silicone resin emulsion to epoxy resin, and stir for 25 minutes at a speed of 200 rpm / min in an oil bath at 55°C to obtain a mixed resin emulsion;

[0067] S3. Add the solution mixture obtained in S1 to the mixed resin emulsion obtained in S2, stir and react at a speed of...

Embodiment 3

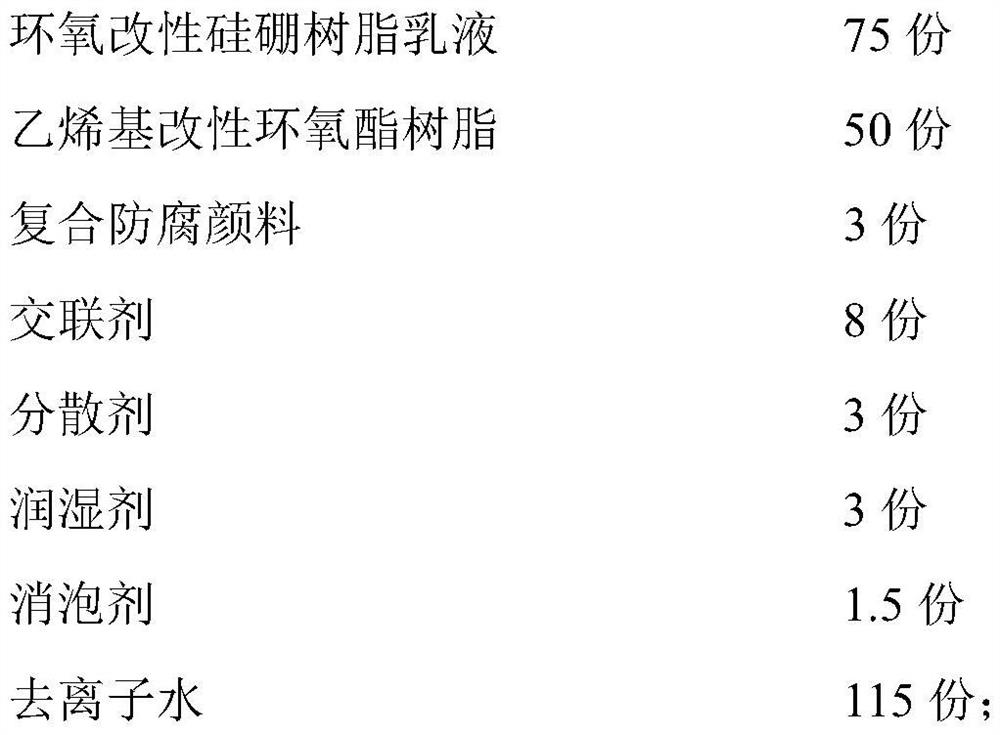

[0082] A high-temperature-resistant and anti-corrosion water-based paint, comprising the following raw materials in parts by weight:

[0083]

[0084] The composite anticorrosion pigment is a hydroxyl-terminated hyperbranched poly(amine-ester) modified graphene oxide / nano aluminum phosphate composite anticorrosion pigment.

[0085] In the present embodiment, the preparation method of the epoxy-modified silicon boron resin emulsion comprises the following steps:

[0086] S1. Mix 30 parts of n-butanol and 15 parts of cyclohexanone, add 100 parts of cyclopropane, and stir at 45°C for 20 minutes at a speed of 300 rpm / min to obtain a solution mixture;

[0087] S2. Add 90 parts of boric acid-modified silicone resin emulsion to 50 parts of epoxy resin, and stir at 250 rpm / min for 35 minutes in an oil bath at 65°C to obtain a mixed resin emulsion;

[0088] S3. Add the solution mixture obtained in S1 to the mixed resin emulsion obtained in S2, stir and react at a speed of 450 rpm / m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com