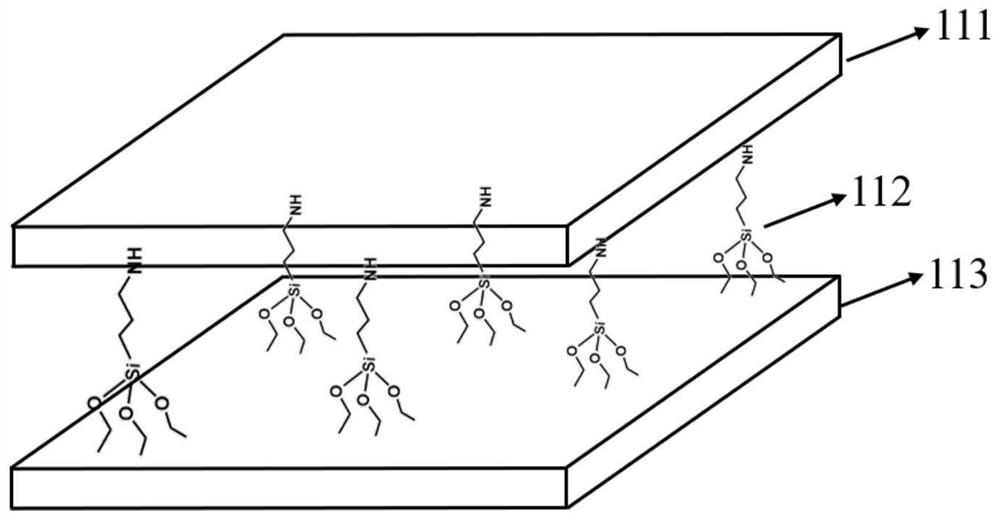

Preparation method of novel extruded polystyrene thermal insulation material/mortar covalent bonding system

A technology of extruded polystyrene and thermal insulation materials, applied in the direction of coating, etc., can solve the problems of difficult control of construction quality and falling off of thermal insulation projects, and achieve the goals of facilitating construction quality control, improving bonding strength, and shortening on-site construction technology Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

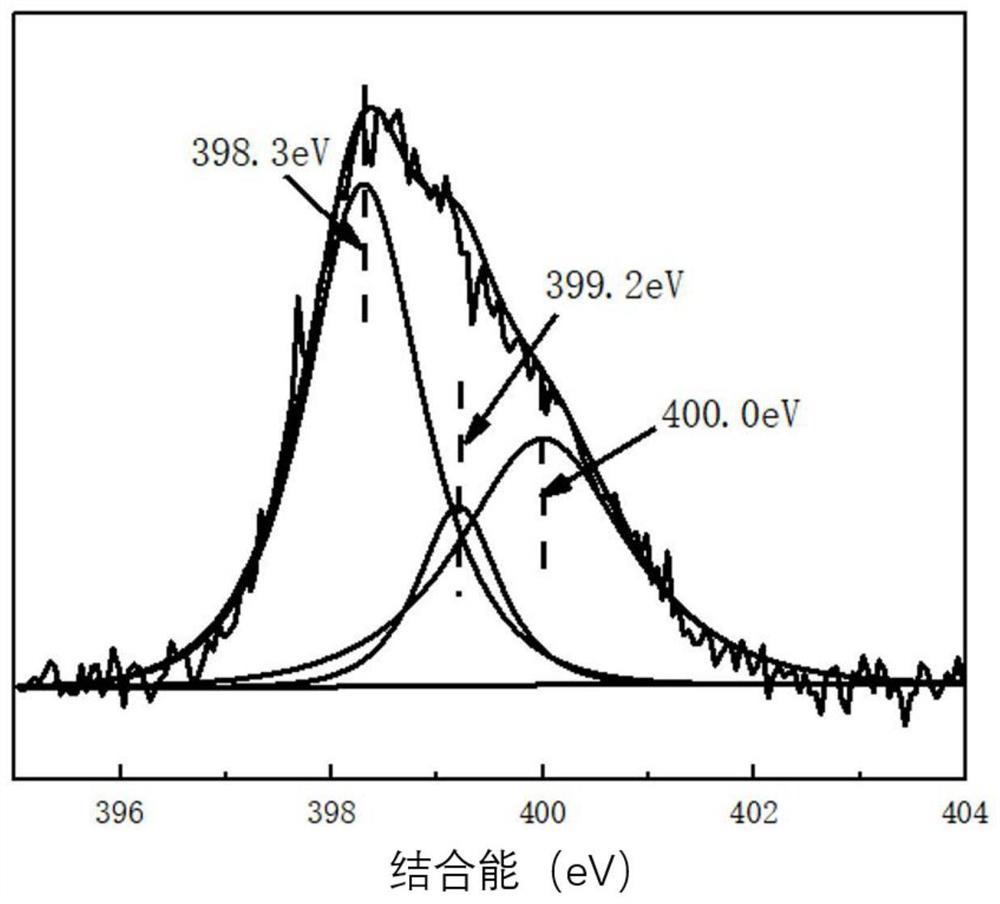

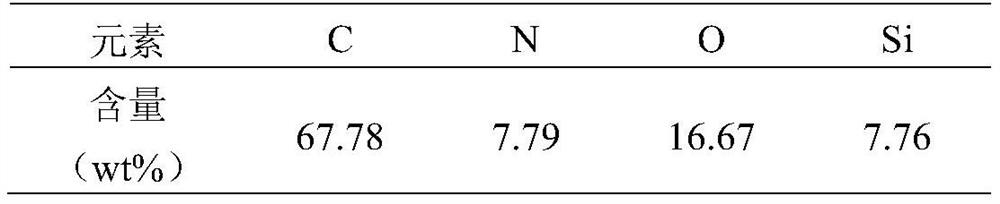

Embodiment 1

[0024] Cut XPS into blocks of 50mm*50mm*50mm for use. Put some XPS plates into the UVO device, set the irradiation time to 7min, adjust the irradiation distance to 9cm, and perform UVO surface activation. At the same time, prepare 0.5 mL (concentration: 2%) of γ-aminopropyltriethoxysilane (KH550) coupling agent solution (the solution is in an alkaline environment), and slowly and evenly drop it onto the surface of the activated XPS plate. The surface coupling reaction was carried out by UVO irradiation again, the irradiation time was 3min, and the irradiation distance was 9cm. After the reaction, the surface of the XPS plate was washed three times with deionized water, and dried in an oven at 40° C. for 15 minutes. Subsequently, apply the evenly stirred plaster mortar on the modified surface of the dried KH550-XPS board, and the thickness of the mortar is controlled at 3mm. The bonding strength test was carried out after curing for seven days under the standard curing condit...

Embodiment 2

[0032] The acidity and alkalinity of the coupling agent solution not only affects the hydrolysis rate of the coupling agent, but also affects the electronegativity of the amino group in the KH550 structure, thereby affecting its reaction characteristics with the activated XPS plate. Therefore, embodiment 2 changes the acidity and alkalinity of the solution.

[0033] Cut XPS into blocks of 50mm*50mm*50mm for use. Put some XPS plates into the UVO device, set the irradiation time to 7min, adjust the irradiation distance to 9cm, and perform UVO surface activation. At the same time, prepare 0.5mL (concentration: 2%) of γ-aminopropyltriethoxysilane (KH550) coupling agent solution (the solution is acidic or neutral environment), and slowly and evenly drop it on the surface of the activated XPS plate . The surface coupling reaction was carried out by UVO irradiation again, the irradiation time was 3min, and the irradiation distance was 9cm. After the reaction, the surface of the XP...

Embodiment 3

[0037] Cut XPS into blocks of 50mm*50mm*50mm for use. Put some XPS plates into the UVO device, set the irradiation time to 10min, adjust the irradiation distance to 9cm, and perform UVO surface activation. At the same time, prepare 0.5mL (concentration: 2%) of γ-mercaptopropyltrimethoxysilane (KH590) coupling agent solution (the solution is in an acidic, neutral or alkaline environment), and slowly and evenly add it dropwise to the activated XPS plate surface for interfacial coupling reaction. After the end, the surface of the XPS plate was washed three times with deionized water, and dried in an oven at 40°C for 15 minutes. Subsequently, apply the evenly stirred plaster mortar on the modified surface of the dried KH590-XPS board, and the thickness of the mortar is controlled at 3mm. The bonding strength test was carried out after curing for seven days under the standard curing conditions of temperature 20±5°C and humidity 40%-60%. The bonding strength between KH550-XPS and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com