A kind of preparation method of perylenetetracarboxylic acid-graphene heterojunction based photoanode material

A technology of perylene tetracarboxylic acid and graphene, which is applied in the field of preparation of perylene tetracarboxylic acid-graphene heterojunction-based photoanode materials, and can solve unfavorable probe molecules, covalent bonding, unfavorable photoelectrochemical sensors, etc. problem, to achieve the effect of improving comprehensive analysis performance and good optical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Example 1: The preparation method of the perylene tetracarboxylic acid-graphene heterojunction-based photoanode material: firstly, the perylene tetracarboxylic acid is synthesized, and then compounded with graphene in a certain proportion. The synthesis process of perylene tetracarboxylic acid is as follows: first, add perylene tetracarboxylic dianhydride into 4% potassium hydroxide solution, and stir at 60°C until it is completely dissolved. Add 0.08 mol L dropwise with stirring -1 Hydrochloric acid solution until pH = 4.5 is obtained, wherein as the pH of the solution decreases, the formation of solid perylenetetracarboxylic acid is accompanied. After it was completely precipitated, it was filtered, washed, and vacuum-dried to obtain red perylene tetracarboxylic acid with a yield of 92.5%.

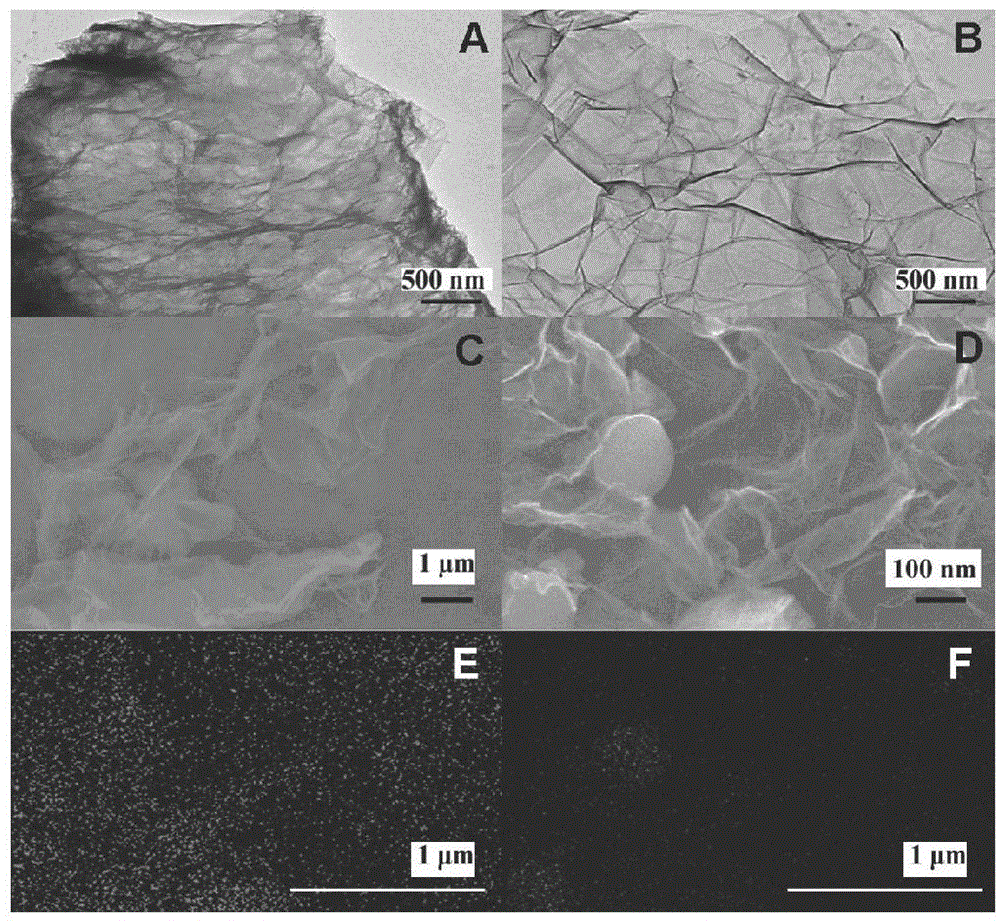

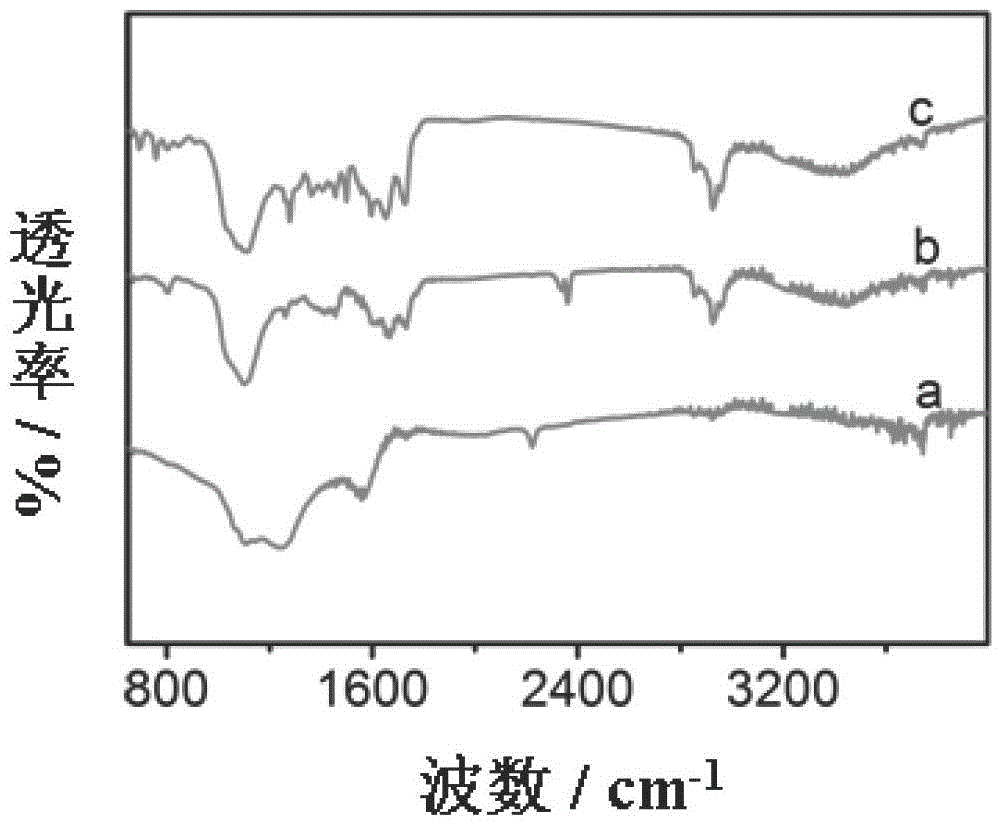

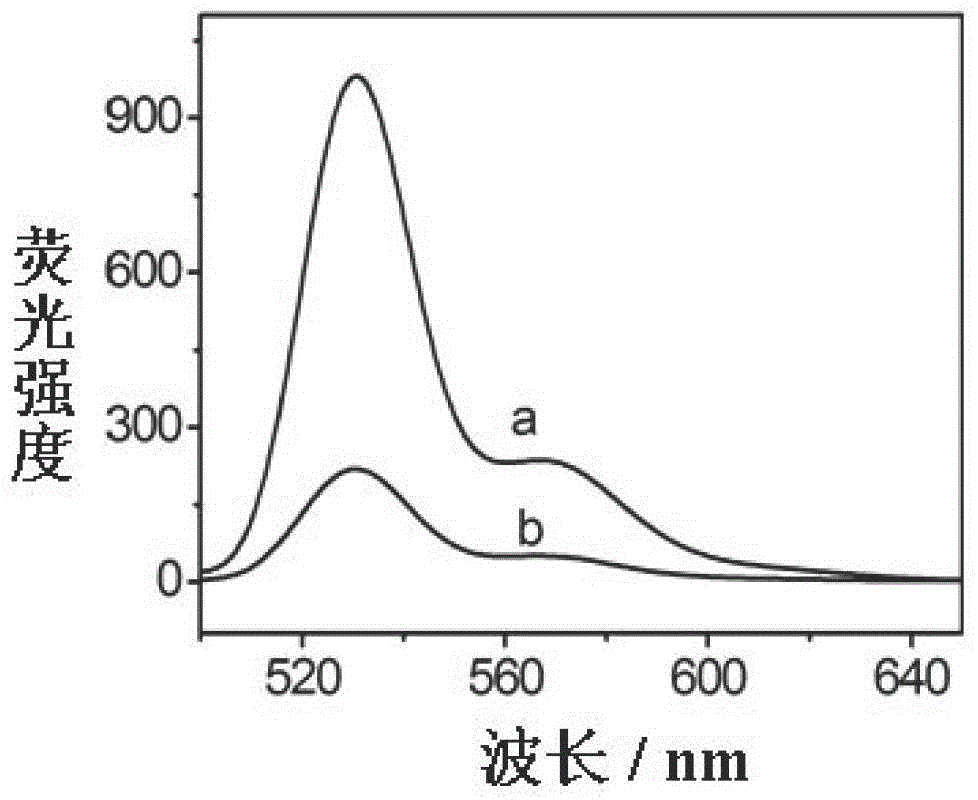

[0017] The specific scheme for preparing perylenetetracarboxylic acid / graphene heterojunction is as follows: First, prepare 0.05×10 -4 mol L -1 DMF solution of perylenetetra...

Embodiment 2

[0020] Example 2: The preparation method of perylene tetracarboxylic acid-graphene heterojunction-based photoanode material: firstly, perylene tetracarboxylic acid is synthesized, and then it is combined with graphene in a certain ratio. The synthesis process of perylene tetracarboxylic acid is as follows: first, add perylene tetracarboxylic dianhydride into 5% potassium hydroxide solution, and stir at 65°C until it is completely dissolved. Add 0.1 mol L dropwise with stirring -1 Hydrochloric acid solution until pH = 4.8 is obtained, wherein as the pH of the solution decreases, the formation of solid perylenetetracarboxylic acid is accompanied. After it was completely precipitated, it was filtered, washed, and vacuum-dried to obtain red perylene tetracarboxylic acid with a yield of 96.5%.

[0021] The specific scheme for preparing perylenetetracarboxylic acid / graphene heterojunction is as follows: First, prepare 1×10 -4 mol L -1 DMF solution of perylenetetracarboxylic ac...

Embodiment 3

[0023] Example 3:The preparation method of perylene tetracarboxylic acid-graphene heterojunction-based photoanode material: firstly, perylene tetracarboxylic acid is synthesized, and then it is combined with graphene in a certain ratio. The synthesis process of perylene tetracarboxylic acid is as follows: first, add perylene tetracarboxylic dianhydride into 6% potassium hydroxide solution, and stir at 70°C until it is completely dissolved. Add 0.12 mol L dropwise with stirring -1 Hydrochloric acid solution until pH = 5.1 is obtained, wherein as the pH of the solution decreases, the formation of solid perylenetetracarboxylic acid is accompanied. After it was completely precipitated, it was filtered, washed, and vacuum-dried to obtain red perylene tetracarboxylic acid with a yield of 97.5%.

[0024] The specific scheme for preparing perylenetetracarboxylic acid / graphene heterojunction is as follows: First, prepare 2×10 -4 mol L -1 DMF solution of perylenetetracarboxylic ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com