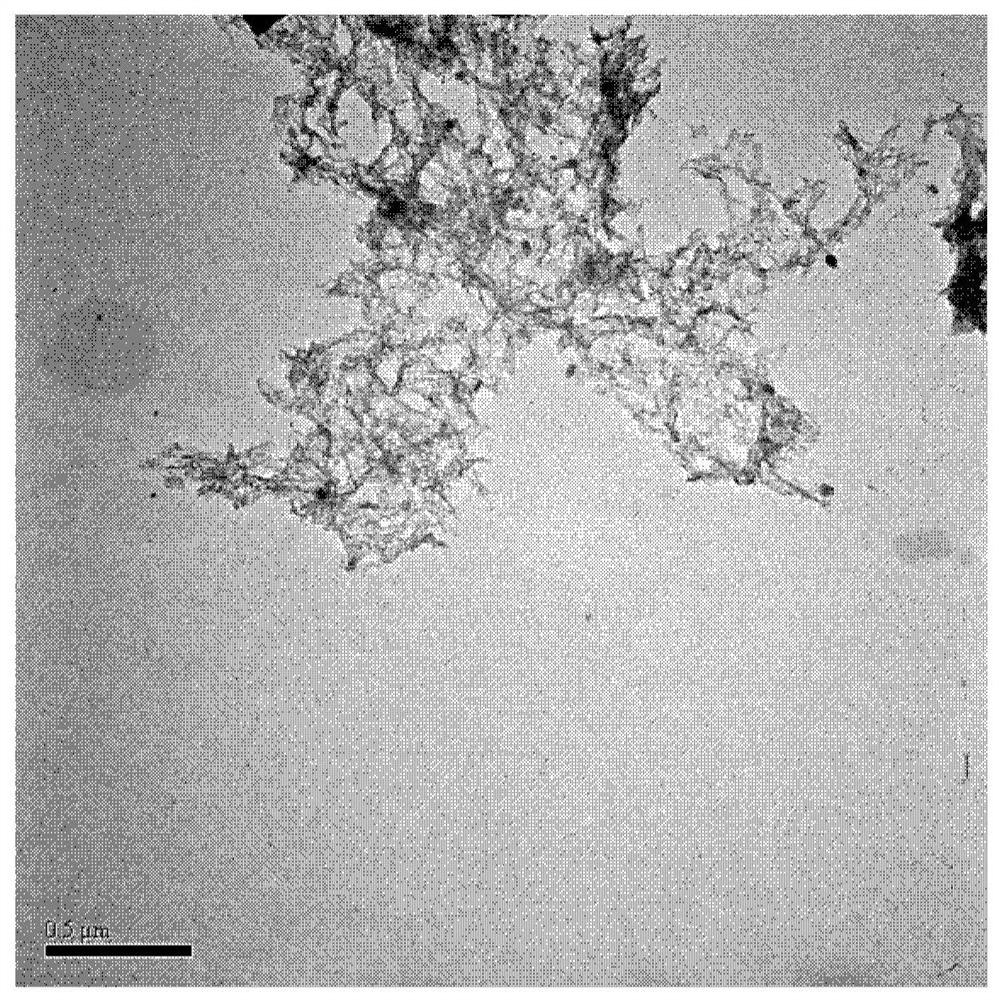

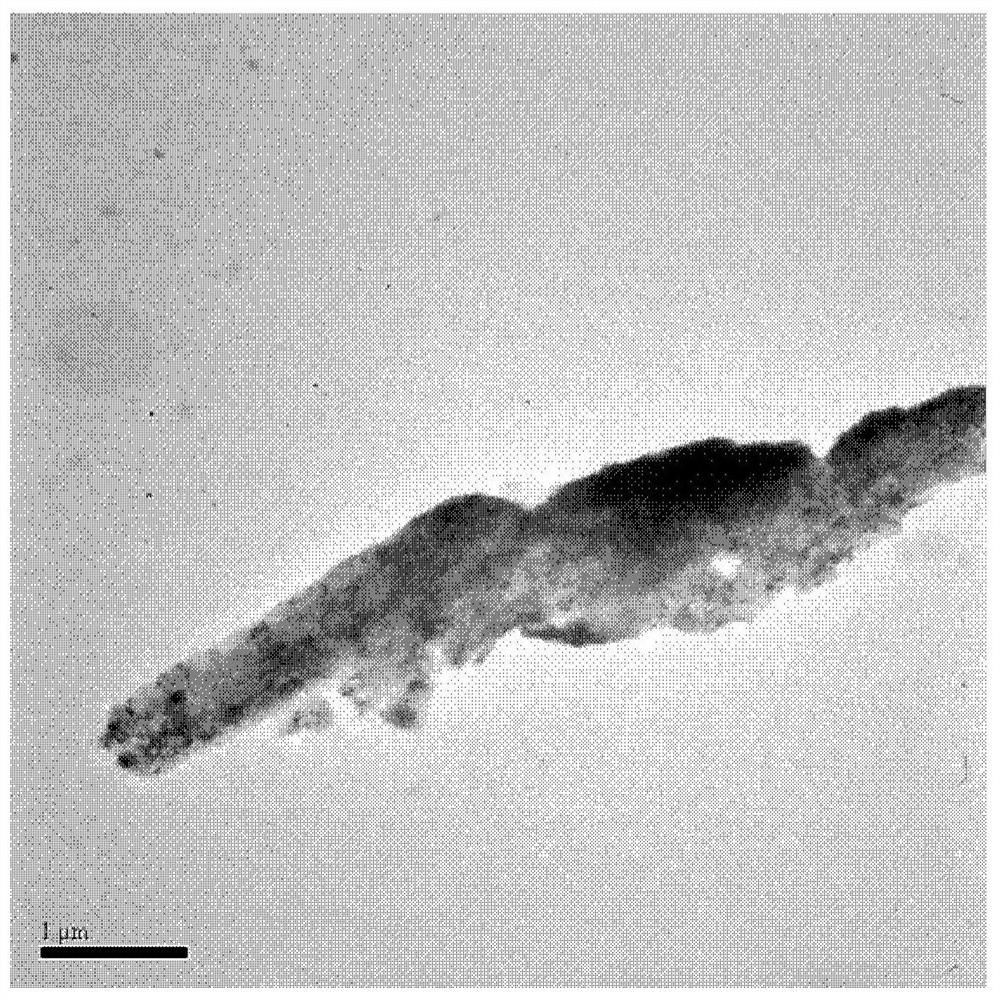

Three-dimensional network graphene airgel, its preparation method and application

A graphene airgel and three-dimensional network technology, applied in the direction of airgel preparation, chemical instruments and methods, colloid chemistry, etc., can solve the problem of less attention to solid-phase carbon sources, achieve excellent adsorption and catalytic performance, Enrich the pore structure and specific surface area, the effect of controllable shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] Specifically, the invention discloses a preparation method of a three-dimensional network graphene airgel, comprising the following steps:

[0019] (1) dissolving the polymer and the transition metal salt in water to obtain a mixed solution;

[0020] (2) Sealing and heating the solution obtained in step (1);

[0021] (3) The product obtained in step (2) is first mixed with the polysaccharide solution, then repeatedly thawed, and then mixed with the transition metal salt solution to form a gel;

[0022] (4) Calcining the gel product obtained in step (3) at a high temperature under a protective atmosphere and metal substrate catalysis, to obtain the three-dimensional network graphene airgel.

[0023] Wherein, the polymer in step (1) can be all aliphatic alcohols such as polyvinyl alcohol and polyethylene glycol, proteins such as gelatin and silk fibroin, and sugars such as agar.

[0024] Wherein, the transition metal salt in step (1) is, for example, salts of all transi...

Embodiment 1

[0038] In this embodiment, the three-dimensional network graphene airgel is prepared by the following specific steps:

[0039] Prepare a mixed solution of polyvinyl alcohol and ferric sulfite, wherein the concentration of polyvinyl alcohol in the final solution is 10 mg / mL, and the concentration of ferric sulfite in the final solution is 0.1 mol / L, and stir to form a uniform solution. Put the mixed solution into a polytetrafluoroethylene-lined stainless steel reaction kettle and heat it at 120°C for 12 hours. After the reaction, dissolve sodium alginate into the product solution. The concentration of sodium alginate is 40 mg / mL, and stir to form a uniform solution. Add the solution dropwise into 100mL 30mg / mL ferric sulfite solution to cross-link sodium alginate and iron ions to form gel balls, freeze the gel balls at -40°C for 12h, then thaw at room temperature for 12h, repeat Cold thaw 3 times to allow polyvinyl alcohol to form a gel. The double network gel was freeze-dried...

Embodiment 2

[0041] Prepare a mixed solution of polyvinyl alcohol and copper nitrate, wherein the concentration of polyvinyl alcohol in the final solution is 10mg / mL, and the concentration of copper nitrate in the final solution is 0.1mol / L, and stir to form a uniform solution. Put the mixed solution into a polytetrafluoroethylene-lined stainless steel reaction kettle and heat it at 200°C for 24 hours. After the reaction, dissolve sodium carboxymethylcellulose in the product solution. The concentration of sodium carboxymethylcellulose is 80 mg / mL. Stir to form a homogeneous solution, drop this solution into 100mL 30mg / mL copper nitrate solution drop by drop, make sodium carboxymethylcellulose cross-link with copper ions to form gel balls, freeze the gel balls at -40°C for 12h , then thawed at room temperature for 12 hours, and repeated freezing and thawing three times to make the polyvinyl alcohol form a gel. The double network gel was freeze-dried to form an aerogel, and the aerogel was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com