Super-elastic flexible three-dimensional composite ceramic nanofiber block as well as preparation method and application thereof

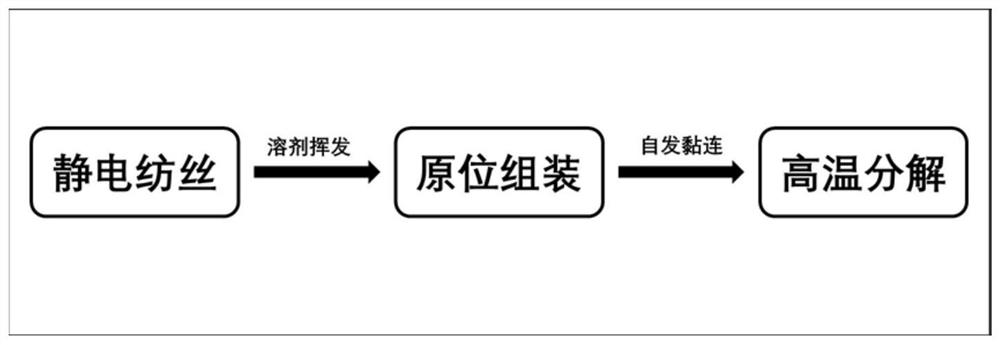

A three-dimensional composite and nanofiber technology, applied in separation methods, chemical instruments and methods, dispersed particle filtration, etc., can solve the problems of complex preparation methods, limited mechanical properties of ceramic fiber membranes, and long time consumption, and achieve large specific surface area and good performance. Thermal stability and chemical stability, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

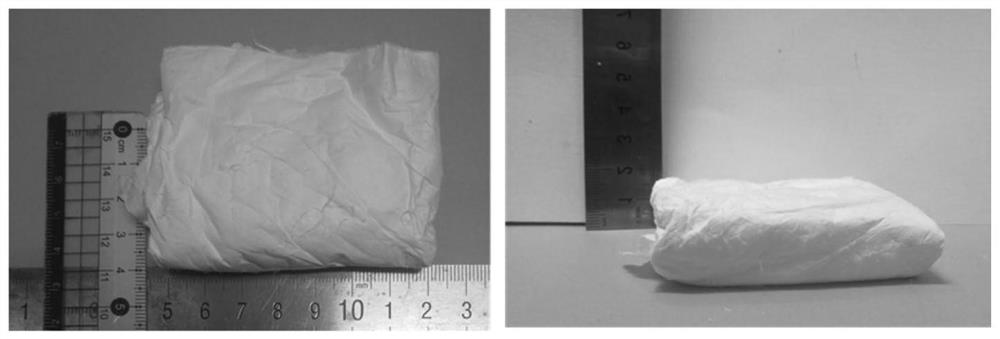

[0021] a. Preparation of alumina / titania three-dimensional composite ceramic nanofiber blocks with a mass fraction of aluminum of 5% by electrospinning:

[0022] First, prepare the electrospinning precursor. Mix 0.6g of PVP powder with 4.5mL of ethanol, stir overnight to obtain a uniform and transparent solution, add 5mL of acetone, 0.22g of aluminum acetylacetonate, 3mL of acetic acid and 2.5mL of isopropyl titanate into the above solution in sequence, and stir at room temperature to make it completely Dissolved to obtain a yellow and transparent precursor solution.

[0023] Secondly, under the conditions of a voltage of 15kV-20kV, a distance between the metal needle and the receiver of 12.5cm, and a flow rate of 0.5mL / h, the fiber film prepared from the above precursor solution was collected after 2 hours, and the film thickness was 10-30μm Between, the spinning environment temperature is required to be 25°C, and the humidity is 30%-40%.

[0024] Under the condition of 40-...

Embodiment 2

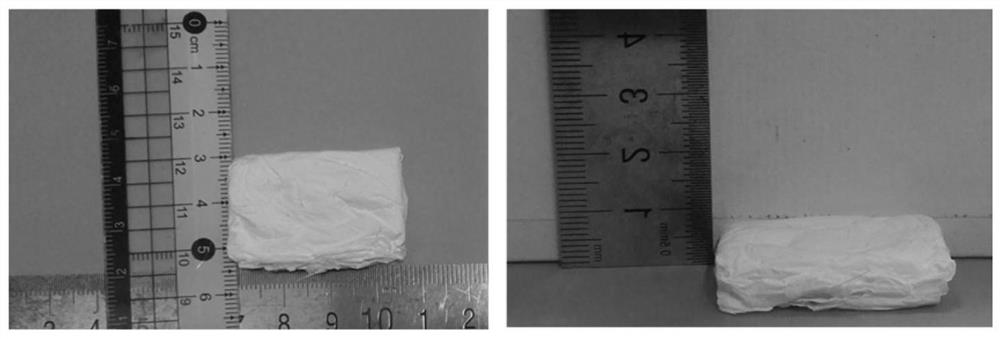

[0029] a. Alumina / titania three-dimensional composite ceramic nanofiber blocks with a mass fraction of aluminum of 15% were prepared by electrospinning:

[0030] First, prepare the electrospinning precursor. Mix 0.6g of PVP powder with 4.5mL of ethanol, stir overnight to obtain a uniform and transparent solution, add 5mL of acetone, 0.73g of aluminum acetylacetonate, 3mL of acetic acid and 2.5mL of isopropyl titanate into the above solution in sequence, and stir at room temperature to make it completely Dissolved to obtain a yellow and transparent precursor solution.

[0031] Secondly, under the conditions of a voltage of 15kV-20kV, a distance between the metal needle and the receiver of 12.5cm, and a flow rate of 0.5mL / h, the fiber film prepared from the above precursor solution was collected after 2 hours, and the film thickness was 10-30μm Between, the spinning environment temperature is required to be 25°C, and the humidity is 30%-40%.

[0032] Under the condition of 40-...

Embodiment 3

[0037] a. Preparation of alumina / titania three-dimensional composite ceramic nanofiber blocks with a mass fraction of aluminum of 30% by electrospinning:

[0038] First, prepare the electrospinning precursor. Mix 0.6g of PVP powder with 4.5mL of ethanol, stir overnight to obtain a uniform and transparent solution, add 5mL of acetone, 1.00g of aluminum acetylacetonate, 3mL of acetic acid and 1.41mL of isopropyl titanate into the above solution in turn, stir at room temperature to make it completely Dissolved to obtain a yellow and transparent precursor solution.

[0039] Secondly, under the conditions of a voltage of 15kV-20kV, a distance between the metal needle and the receiver of 12.5cm, and a flow rate of 0.5mL / h, the fiber film prepared from the above precursor solution was collected after 2 hours, and the film thickness was 10-30μm Between, the spinning environment temperature is required to be 25°C, and the humidity is 30%-40%.

[0040] Under the condition of 40-60wt.%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com