A kind of wet rubbing fastness improving agent for acid dyes and preparation method thereof

A technology of wet rubbing fastness and acid dyes, applied in dyeing method, textile and papermaking, etc., can solve the problems of complex synthesis process, poor wet rubbing fastness, strict color fixing process, etc., to improve film-forming performance and fixing ability , reduce entanglement, reduce the effect of violent gathering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

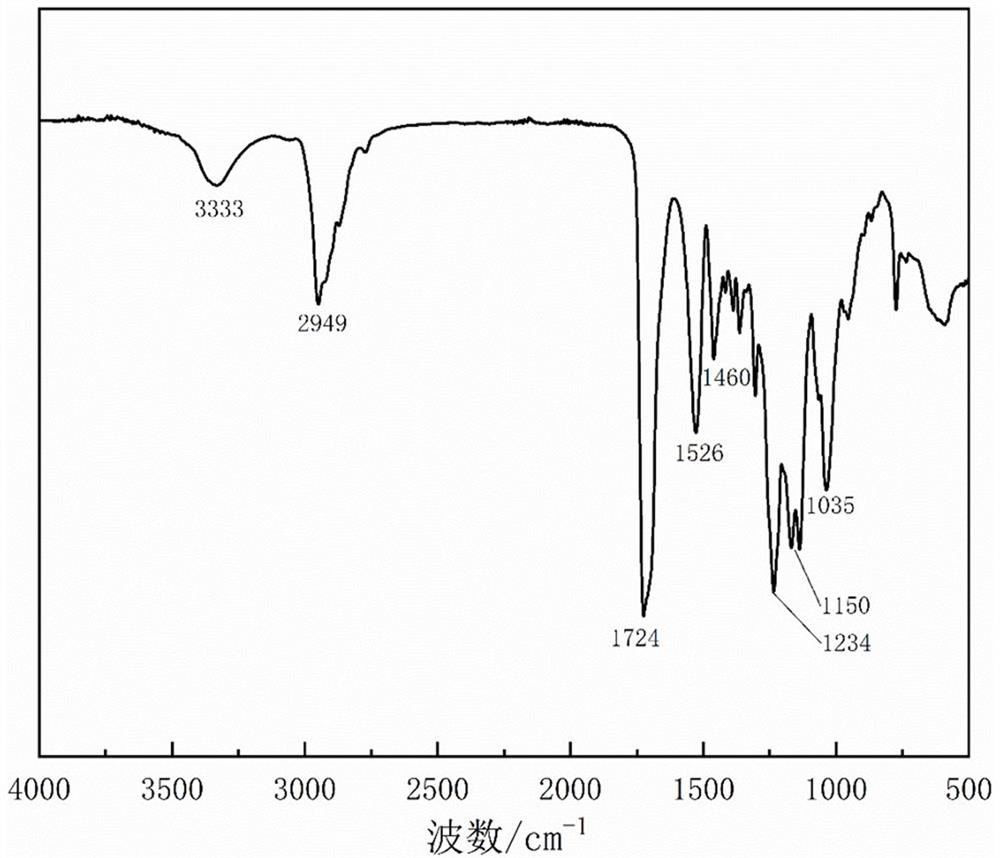

Embodiment 1

[0027] (1) Add 9.1g of serinol, 31.4g of 88% formic acid solution, and 18.4g of 37% formaldehyde solution into a reaction vessel with a stirrer and condensing reflux device, turn on the stirring and condensing reflux device, and react at 25°C After 2 hours, gradually raise the temperature to 80°C, and keep at this temperature for 8h; adjust the temperature to 70°C, pressure to -0.1MPa, and recover most of the water and formic acid by vacuum distillation; cool to 25°C, and gradually add sodium hydroxide Adjust the pH to 12, dissolve with anhydrous methanol and filter, heat the filtrate to 60°C, and pressure to -0.1MPa, distill under reduced pressure to recover methanol, and obtain the chain extender as light yellow oil.

[0028] (2) Mix 20g of polyethylene adipate diol with 4g of acetone and add it into a reaction vessel with a stirrer and condensation reflux device; turn on the reflux device and stirrer, gradually raise the temperature to 70°C, and add 0.03g After dibutyltin d...

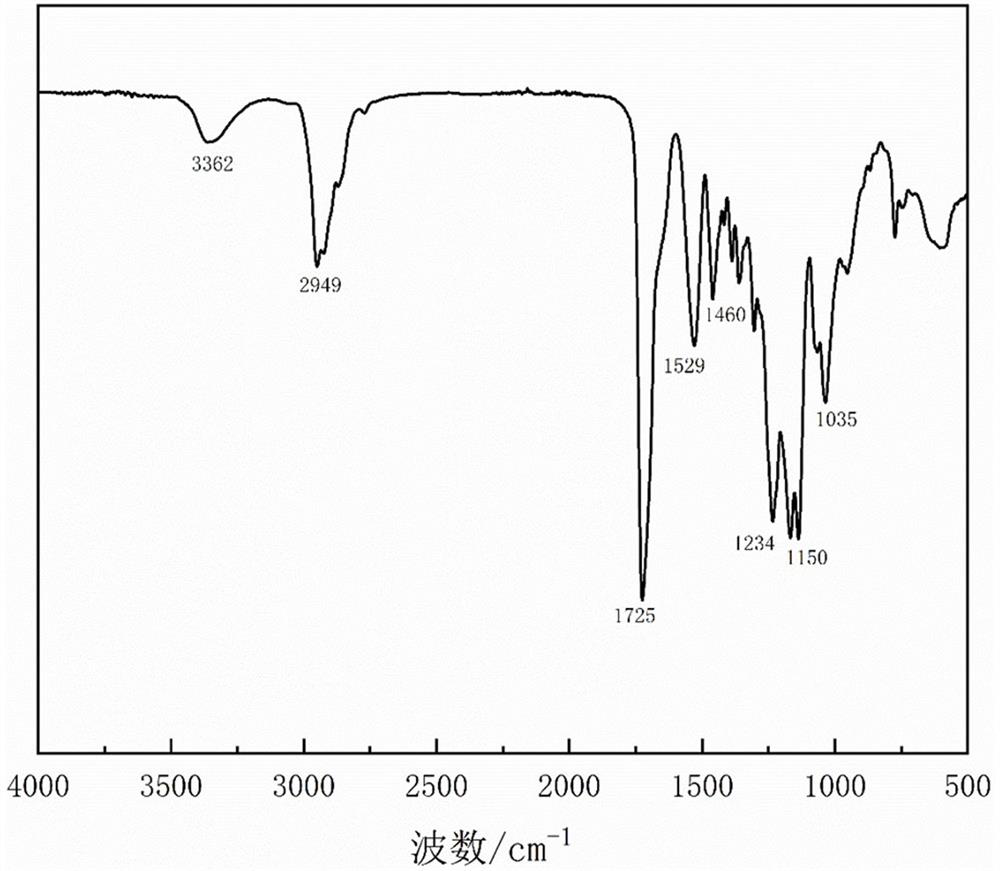

Embodiment 2

[0031](1) Add 9.1g of serinol, 31.4g of 88% formic acid solution, and 18.4g of 37% formaldehyde solution into a reaction vessel with a stirrer and condensing reflux device, turn on the stirring and condensing reflux device, and react at 25°C After 2 hours, gradually raise the temperature to 80°C, and keep at this temperature for 8h; adjust the temperature to 70°C, pressure to -0.1MPa, and recover most of the water and formic acid by vacuum distillation; cool to 25°C, and gradually add sodium hydroxide Adjust the pH to 12, dissolve with anhydrous methanol and filter, heat the filtrate to 60°C, and pressure to -0.1MPa, distill under reduced pressure to recover methanol, and obtain the chain extender as light yellow oil.

[0032] (2) Mix 20g of polyethylene adipate diol with 4g of acetone and add it into a reaction vessel with a stirrer and a condensing reflux device; turn on the reflux device and agitator, gradually raise the temperature to 70°C, and add 0.06g After dibutyltin d...

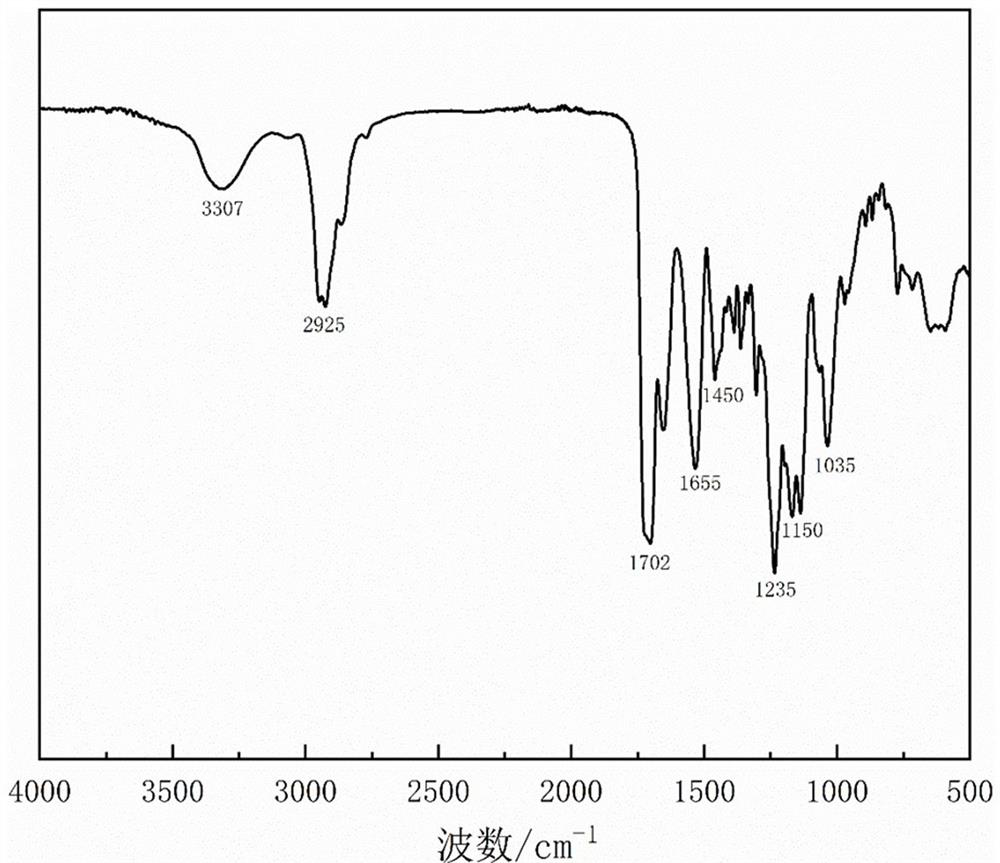

Embodiment 3

[0035] (1) Add 9.1g of serinol, 31.4g of 88% formic acid solution, and 18.4g of 37% formaldehyde solution into a reaction vessel with a stirrer and condensing reflux device, turn on the stirring and condensing reflux device, and react at 25°C After 2 hours, gradually raise the temperature to 80°C, and keep at this temperature for 8h; adjust the temperature to 70°C, pressure to -0.1MPa, and recover most of the water and formic acid by vacuum distillation; cool to 25°C, and gradually add sodium hydroxide Adjust the pH to 12, dissolve with anhydrous methanol and filter, heat the filtrate to 60°C, and pressure to -0.1MPa, distill under reduced pressure to recover methanol, and obtain the chain extender as light yellow oil.

[0036] (2) Mix 20g of polyethylene adipate diol with 4g of acetone and add it into a reaction vessel with a stirrer and condensation reflux device; turn on the reflux device and stirrer, gradually raise the temperature to 70°C, and add 0.03g After dibutyltin d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com