A kind of screen printing protective ink composition and screen printing method

A technology for protecting inks and compositions, applied in the direction of inks, printing, printing devices, etc., can solve the problem of unstable size in the sandblasting step and achieve good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] First, prepare the screen printing protection ink composition in the present invention: first prepare the acid-resistant ink and the amine curing agent in proportion and stir evenly, then add superfine Stir the rubber powder and diluent (ketone solvent) evenly; the weight ratio is ink:curing agent:diluent:rubber powder=100:1:8:10. Among them, the acid-resistant ink is the acid-resistant ink of the model IP-505-03 produced by Matsui Chemical, the ultra-fine rubber powder is the ultra-fine rubber powder produced by Mingjintai Rubber and Plastic Products Company, and the curing agent is the model DA-043 produced by Matsui Chemical The amine solidifying agent, the diluent is the ketone-containing solvent of the model KJ001 that Matsui Chemical produces.

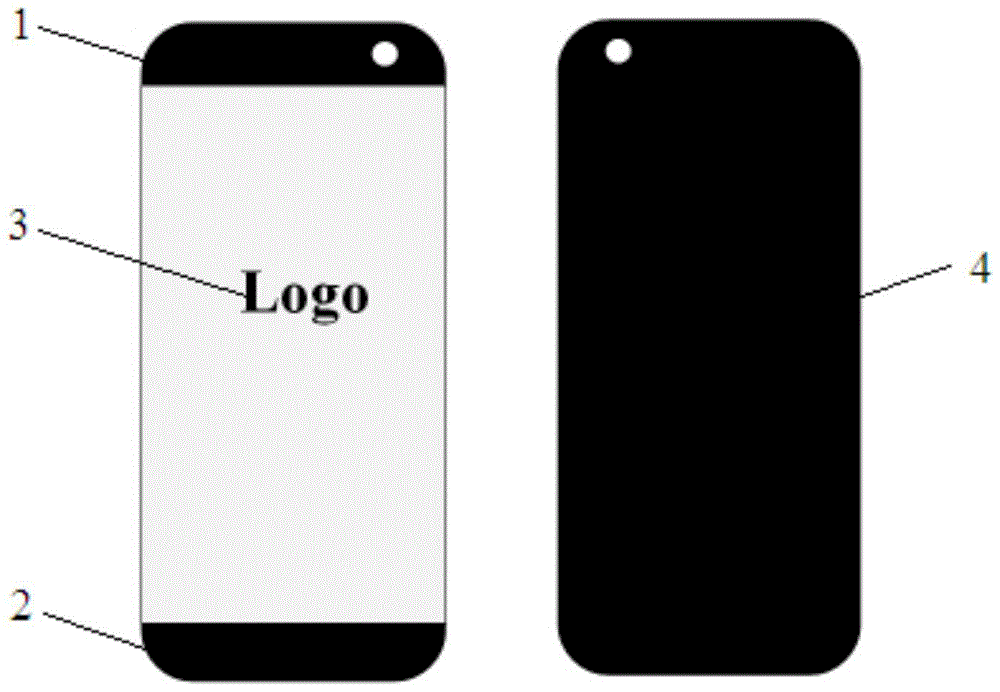

[0028] Preparation: Prepare the screen version (screen version of about 120T mesh), screen printing machine and such as figure 1 The shapes and dimensions shown in are all processed white glass.

[0029] Silk screen prin...

Embodiment 2

[0033] The weight ratio of the screen printing protective ink composition in this embodiment is ink:curing agent:diluent:rubber powder=100:0.8:8:8, and the rest of the conditions are the same as in Example 1. The obtained screen printing protective ink composition can play an ideal protective effect when used for screen printing.

Embodiment 3

[0035] The weight ratio of the screen printing protective ink composition in this embodiment is ink:curing agent:diluent:rubber powder=100:1.2:10:15, and the rest of the conditions are the same as in Example 1. The obtained screen printing protective ink composition can play an ideal protective effect when used for screen printing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com