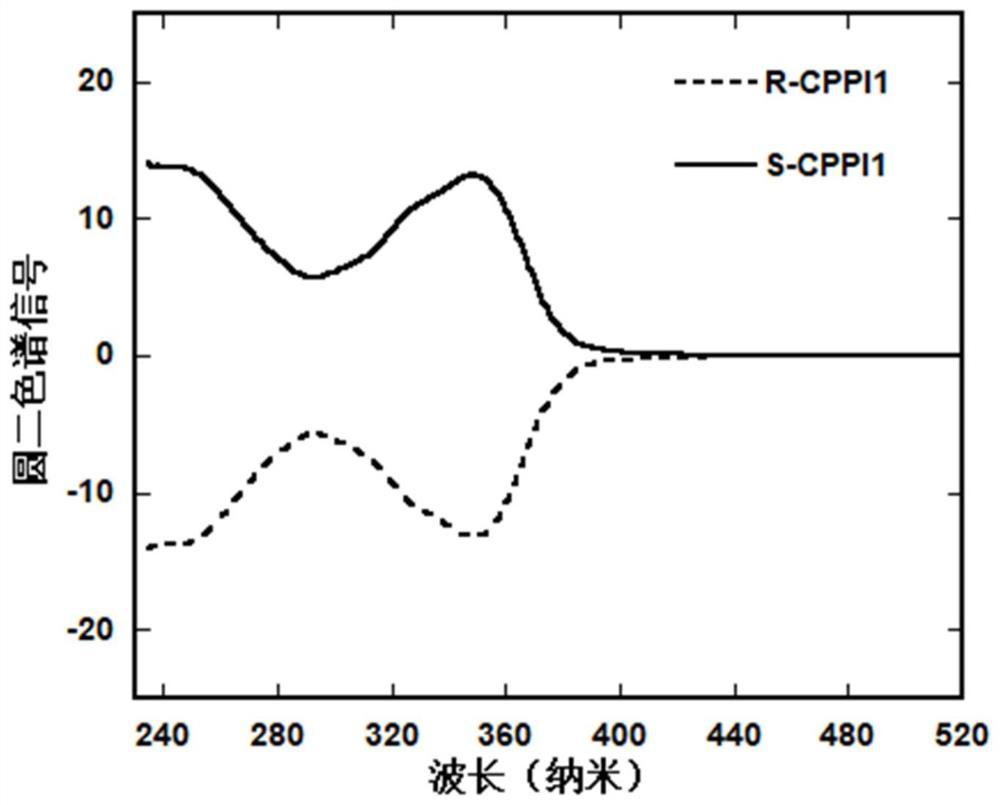

A kind of phenanthroimidazole electroluminescent material with circularly polarized luminescence and its preparation method and application

An electroluminescent material, phenanthroimidazole technology, applied in the direction of luminescent materials, chemical instruments and methods, circuits, etc., can solve the problems of material types or quantities, and performance needs to be improved, so as to achieve commercial application and improve device electrical Luminescent properties, easy synthesis of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0086] (5) Preparation of compound CPPI1

[0087] Under argon atmosphere, 2-fluorobenzo[b]dinaphtho[2,1-e:1',2'-g][1,4]dioxan (1.89 g, 5 mmol) and 1-( 4-tert-butylphenyl)-2-(4-(4,4,5,5-tetramethyl-1,3,2-dioxaborolan-2-yl)phenyl)-1H-phenanthrene [9,10-d]imidazole (4.26g, 7.5mmol), catalyst tetraphenylphosphine palladium (Pd(PPh 3 ) 4) (0.29g, 0.25mmol) was dissolved in toluene, then an alkaline potassium carbonate aqueous solution (50% by mass, 3.45g / 3.45mL deionized water, 25mmol) was added, reacted at 100°C for 16h, after the reaction was stopped, quenched with water Reaction, extraction with dichloromethane and drying with anhydrous magnesium sulfate, the solution was concentrated to obtain a khaki liquid, purified by silica gel column chromatography, petroleum ether and dichloromethane mixed solvent (volume ratio 3:1) as eluent As eluent, a white solid was obtained with a yield of 72%. 1 H NMR, 13 C NMR, MS and elemental analysis results show that the compound obtained...

Embodiment example 18

[0108] Fabrication of Organic Electroluminescent Devices

[0109] 1) Cleaning of ITO conductive glass. Place the ITO glass substrate on the film rack, and use an ultrasonic machine to ultrasonically clean it. The washing liquid is used in the order of acetone, isopropanol, detergent, deionized water and isopropanol. The purpose is to fully remove the ITO glass substrate. Stains that may remain on the surface of the chip, such as photoresist, etc., and improve interface contact. Then dry in a vacuum oven;

[0110] 2) ITO is placed in an oxygen plasma etcher, using oxygen plasma (O 2 Plasma) carries out the bombardment of 20 minutes, thoroughly removes possible residual organic matter on the surface of the ITO glass substrate;

[0111] 3) Spin-coat a 40nm-thick hole injection layer PEDOT:PSS (Baytron P4083) on the ITO, and then dry it in a vacuum oven at 80°C for 12 hours;

[0112] 4) Spin-coat a layer of 80nm-thick phenanthroimidazole electroluminescent material with circu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com