High-temperature-resistant inorganic adhesive and preparation method thereof

A technology of inorganic glue and high temperature resistance, applied in the direction of electrical components, circuits, electric solid devices, etc., can solve the problems of low bonding strength, aging, molecular dissociation damage, etc., and achieve good acid and alkali resistance and high temperature resistance , the effect of good adhesive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

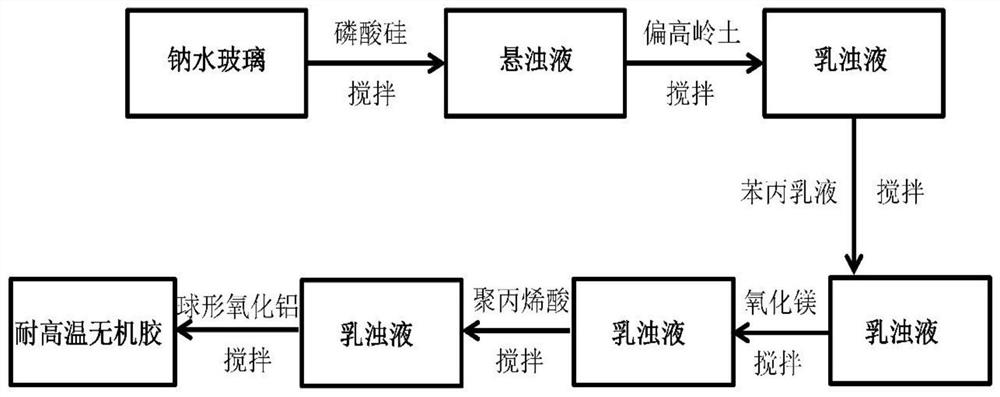

Method used

Image

Examples

Embodiment 1

[0037] Make a kind of high temperature resistant inorganic glue, this high temperature resistant inorganic glue is configured according to the following parts by weight: 60% sodium water glass, 32% metakaolin, 5% silicon phosphate, 0.2% styrene-acrylic emulsion, 0.5% magnesium oxide, 0.3% Polyacrylic acid, 2% spherical alumina;

[0038] The Baume degree of sodium water glass solution among the present invention is 39, and modulus is 3.2;

[0039] The average particle size of metakaolin is 10μm;

[0040] The average particle size of spherical alumina is 30um;

[0041] Preparation method: The following preparation methods are carried out at room temperature.

[0042] Use sand core movable filtering device, use 200 order filter screens to filter the sodium water glass solution for 30 minutes, obtain the sodium water glass after the suction filtration; Add the silicon phosphate under the weight ratio in the sodium water glass after the suction filtration, in Stir for 2min at a ...

Embodiment 2

[0050] The high temperature resistant inorganic glue includes the following raw materials in parts by weight: 60% sodium water glass, 29.5% metakaolin, 5% silicon phosphate, 0.2% styrene-acrylic emulsion, 1.0% magnesium oxide, 0.3% polyacrylic acid and 4% spherical oxide aluminum;

[0051] The Baume degree of the sodium water glass solution is 42, and the modulus is 2.8;

[0052] The average particle size of the metakaolin is 30 μm;

[0053] The average particle diameter of the spherical alumina is 20um;

[0054] Preparation method: The following preparation methods are carried out at room temperature.

[0055]Use sand core movable filtering device, use 200 mesh filter screens to suck and filter sodium water glass solution for 30 minutes, obtain the sodium water glass after suction filtration; Add silicon phosphate under the weight proportion in the sodium water glass after suction filtration, in Stir for 2min at a stirring rate of 200r / min to mix the two to obtain a suspen...

Embodiment 3

[0057] The high-temperature-resistant inorganic glue includes the following raw materials in parts by weight: 54% sodium water glass, 38.5% metakaolin, 4% silicon phosphate, 0.3% styrene-acrylic emulsion, 0.5% magnesium oxide, 0.7% polyacrylic acid and 2% spherical oxide aluminum;

[0058] The Baume degree of the sodium water glass solution is 43, and the modulus is 2.6;

[0059] The average particle size of the metakaolin is 50 μm;

[0060] The average particle diameter of the spherical alumina is 25um;

[0061] Preparation method: The following preparation methods are carried out at room temperature.

[0062] Use sand core movable filtering device, use 200 mesh filter screens to suck and filter sodium water glass solution for 30 minutes, obtain the sodium water glass after suction filtration; Add silicon phosphate under the weight proportion in the sodium water glass after suction filtration, in Stir at a stirring rate of 300r / min for 3min to mix the two to obtain a suspe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com