Photocatalyst, preparation method thereof and method for producing hydrogen by photolysis of water

A photocatalyst and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, hydrogen production, etc., can solve the problem that the valence band and conduction band potentials cannot be satisfied at the same time, the utilization rate of sunlight is low, and the quantum efficiency is reduced, etc. problem, to achieve the effect of improving migration and separation efficiency, excellent photocatalytic production, and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

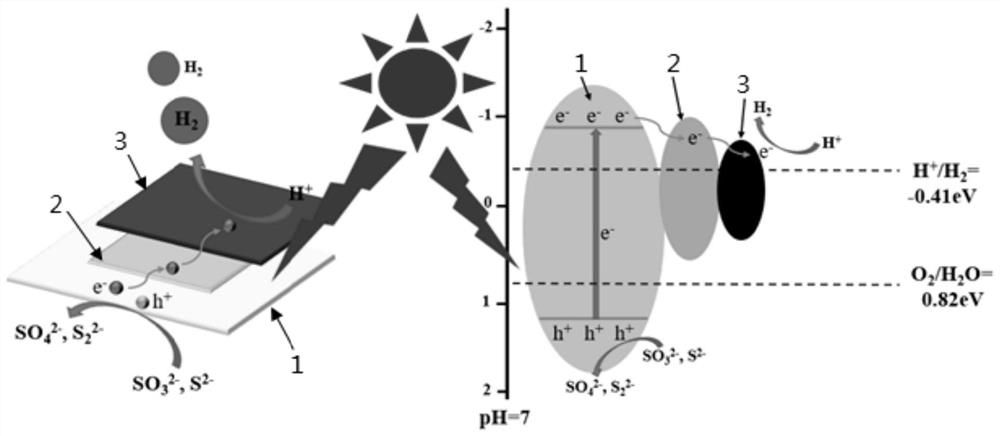

[0031] As an embodiment, the first semiconductor nanosheet is a main catalyst, and the second semiconductor nanosheet is a co-catalyst, forming a photocatalyst loaded on the co-catalyst and having good photocatalytic hydrogen production activity.

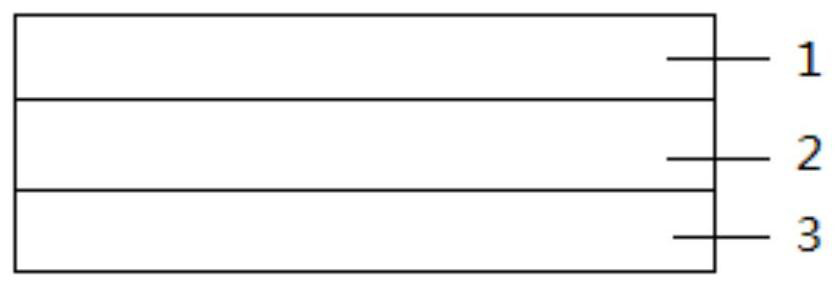

[0032] As an implementation, such as figure 1 As shown, the first semiconductor nanosheet 1, the two-dimensional carbon nanomaterial 2 and the second semiconductor nanosheet 3 are stacked in sequence.

[0033] The first semiconductor nanosheet, the two-dimensional carbon nanomaterial, and the second semiconductor nanosheet all have a sheet-like structure, and the first semiconductor nanosheet, the two-dimensional carbon nanomaterial, and the second semiconductor nanosheet are sequentially stacked to form a sandwich-like structure. photocatalyst with composite structure. On the one hand, the formed photocatalyst has a larger interface contact area, and makes the contact between the layers closer, and promotes the rapid transfer of p...

Embodiment 1-3

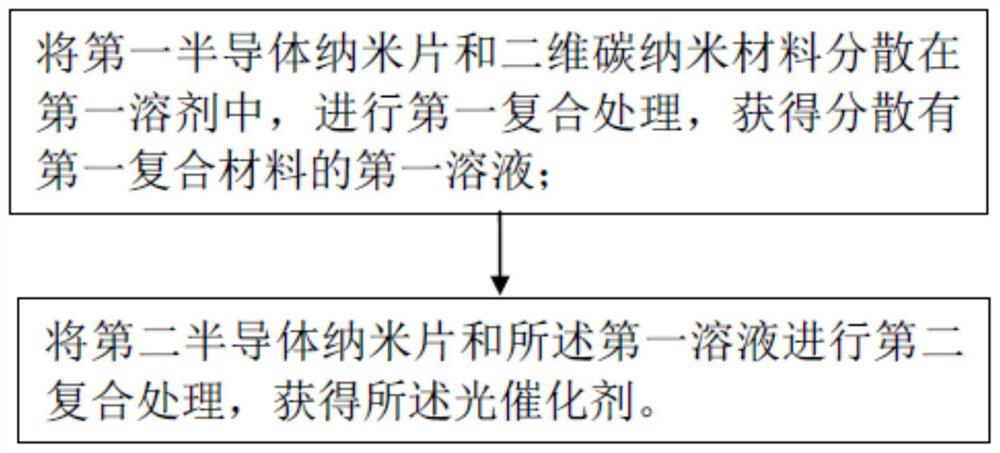

[0077] This embodiment provides a photocatalyst g-C 3 N 4 / RGO / MoS 2 , its preparation method specifically includes:

[0078] 1. Preparation of g-C 3 N 4

[0079] Put 10 g of urea into the crucible, place it in a muffle furnace for calcination at 600°C for 2 hours, and heat up at a rate of 5°C / min. The calcined product is washed with distilled water, filtered, dried in an oven, and ground to obtain g-C 3 N 4 .

[0080] 2. Preparation of graphene oxide (GO)

[0081] Add 360mL of concentrated sulfuric acid and 40mL of phosphoric acid to 3g flake graphite, mechanically stir in an ice-water bath for 10min, then add 18g of potassium permanganate, stir for 30min and mix well, heat in a water bath at 50°C for 24h, add 300mL of distilled water after the reaction is completed, then mechanically stir for 1h, slowly drop Add 20mL of 30% hydrogen peroxide, and the reaction solution gradually turns from brown to golden yellow. After centrifugation, soak in 500mL of 5% hydrochloric...

Embodiment 4-6

[0091] This embodiment provides a photocatalyst CdS / acetylene black / MoS 2 , its preparation method specifically includes:

[0092] 1. Preparation of Cds nanosheets

[0093] 0.4g sublimated sulfur powder and 0.45g CdCl 2 2.5H 2 O was dissolved in 75mL of diethylenetriamine (DETA) and stirred for 1h to mix well, the mixture was transferred to a 100mL polytetrafluoroethylene-lined reaction kettle, heated to 80°C in an oven and kept for 45h, and then naturally cooled to room temperature A pale yellow product was obtained by centrifugation at 3000 rpm. Then the product was washed three times with deionized water and absolute ethanol respectively, and dried in a vacuum oven at 60° C. for 8 h to obtain CdS nanosheets.

[0094] 2. Preparation of MoS 2 Nanosheets

[0095] Dissolve 0.48g of sodium molybdate and 0.8g of thioacetamide in 60mL of deionized water and continue to stir for 1h to obtain a clear solution; then, transfer the clear solution to a 100mL polytetrafluoroethylen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com